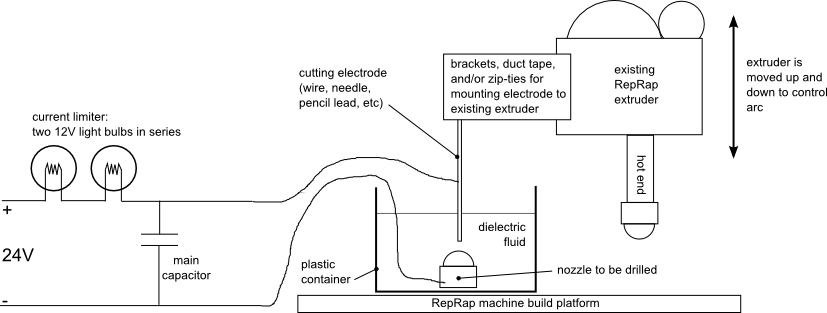

Electrical Discharge Machining

Electrical Discharge Machining. Basically it applies electric fields strong enough to break up the material. Of course a plasma forms(or a spot-weld potentially) that increases conduction and decreases the field, so then something is done to stop the current, like raising the conductor away.

a forum thread, MattMoses build one around 2001.

From that forum thread:

24V,12V might both work.

The purpose of the dielectric fluid is move the material out and cool. pdf with more information. Vegetable oil or distilled water can work for removing material. Flash point(fire!) might be an issue for some fluids. (I expect for now that is sufficient?)

For stopping the current MatMoses used a servo. a coil that pulls on a magnet/ferromagnetic material might also work and use the current of the discharge itself.