Dual drive geared extruder

Release status: working

| Description | A dual drive geared extruder made with savaged gears.

|

| License | |

| Author | |

| Contributors | |

| Based-on | |

| Categories | |

| CAD Models | |

| External Link |

Introduction

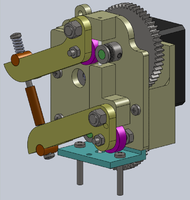

The Flow Rate of an extruder is one of the main issues to reach high print speeds. Trying to push the limits of flow rate in direct-drive extruders leads to motor stall or filament smashing. A geared extruder, as Wade's, increases the torque available to the hobbed gear. The motor is less prone to stall, but smashing filament is still an issue. With two hobbed gears pushing the filament, the force is distributed over larger area, so I started to try some projects that use dual gear extrusion. Up to now I found two designs of double-geared extruders that work nicely, but I decided to develop another one with minor changes. This project describes a geared dual drive made with savaged gears from an old laser printer.

Overview

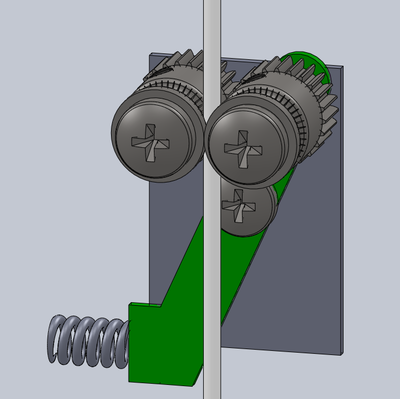

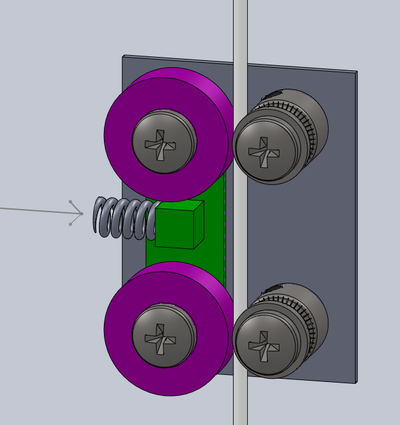

[1] shows a large assortment of dual drive extruder designs. Those extruders have one hobbed drive connected to the motor shaft and other hobbed drive conducted by a spring loaded lever, as shown in the figure below. Two gears joined to the drivers are responsible for the dual drive characteristic: the filament is griped in two sides at same time.

But there are some objections to this design (and to the designs of direct drive extruders as well). The lever drive press the filament against the motor drive and this causes a radial force applied to the motor shaft. Motors in general are projected to exert only torque and do not cope well with radial forces. The company Applied Motion Products[2] have an excellent documentation with lots of specs about the subject. In this document it is recommended that the maximum radial force applied to a Nema 17 motor shaft ranges from 20 to 30 N. A spring used in an extruder's lever can easily exert a force of 10 N. The distances between the spring, pivot and drive can result in a gain of momentum that generates forces well above 30 N over the motor shaft. Considering that the specifications given by Applied Motion Products are for good quality motors, cheap motors could be in real danger. Some issues about this problem have been reported in RepRap forum [3].

There is another objection to this design: The distance between gears depends on the filament hardness. For a soft ABS filament the driver's teeth could smash the filament so that the gears touch each other to the limit and avoid the driver's teeth to penetrate further. For a hard PLA filament the distance between the gears could be large enough to cause backlash. As I like gears touching in its primitive diameter or even a little bit tighter, I preferred to look for another solution.

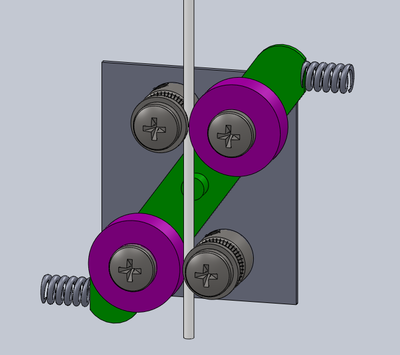

Ryan Huang - yyh1002 - shows a Belted Dual Drive [4] that circumvents the gear distance problem described. The two drivers and the motor shaft are interconnected by a timing belt. The figure bellow shows the mechanical aspect of this design. The spring press the two bearings against the filament. The radial forces are applied to shafts sported by bearings and not to the motor shaft. But there is still a radial force over the motor shaft caused by the timing belt tension.

What annoys me in this design is that the filament is griped and smashed in just one side. After passing through the upper drive, the second drive will encounter an already ground filament.