DrillandFile Hot End

Release status: Working

| Description | A simple DIY hotend which can be made with only a drill press and hand tools

|

| License | GPL

|

| Author | |

| Contributors | |

| Based-on | |

| Categories | |

| CAD Models | |

| External Link |

Making your own hotend is like baking your own bread - there might be professionals out there who can bake better and have superior gadgets to do so, but nothing compares to your own, self-made bread.

This hotend is just another attempt at designing a simple hotend which can be made DIY-style without the need for expensive tools, machinery and materials. It was inspired by the Watson_Hot_End, the KISS_Hot_End and the Wildseyed_Simple_Hot_End.

The basic idea is to drill first, then file in shape. That is, you take a rectangular block of aluminium alloy, drill the holes for the ptfe sleeve and the nozzle first, and then start filing the block into its final shape. That way, the drilling precision that can be reached with a simple drill press is not critical, you can more or less drill slightly off-center and still end up with a very precise hotend after filing.

The heater block is drill/saw/file, the bracket is drill/saw and the insulator is drill/cut only. There is now lathe or milling required, neither for the heater block nor for the insulator. The M4 thread in the heater block (for attaching to the bracket) can easily be tapered by hand.

The materials are cheap, a single hotend costs probably no more than 5 EUR as far as material is concerned. However, to source the material, you probably need to buy slightly larger quantities (for example, you cannot buy a 20x35x12mm piece of aluminum alloy, you need to buy 20cm of 20x35mm bar at ebay for approx. 5 EUR - which you can use to build more than 15 heater blocks). I have bought material for approx. 30-40 EUR and now have enough in stock to build at least 10 hotends, that is, 6 more to go.

Summary:

- electric tools required: drill press

- common hand tools required: saw, file(s), drill bits 5mm, 3.2mm, 2mm, M4 inside tap

- special hand tools required: hand chuck and 0.5mm or 0.3mm drill bits for nozzle

- materials required: aluminium bar 20x35mm for heater, PTFE round material 5mm and 15mm OD for insulator, 3mmx20mm steel bar for bracket

- vitamins required: 2 power resistors 6.8R, thermistor, high-temperature silicon caulk

- skills: drill, file and tap an M4 thread

Contents

Status

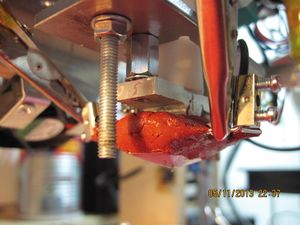

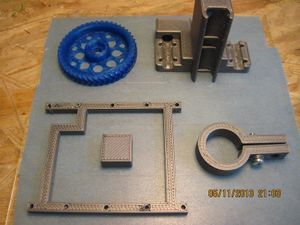

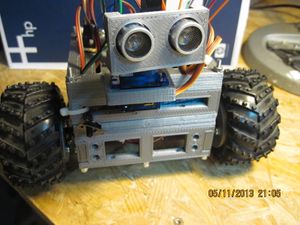

The current version is v3 and works quite well. Besides printing calibration pieces and robotics parts, I have used it to print all parts for my Mendel90.

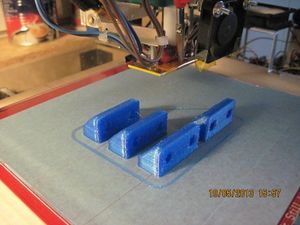

Here are some examples of prints made with v2 and v3 with a 0.5mm nozzle:

Component Overview and Functional Description

the main components are:

- heater block

- bracket

- insulator

Heater Block

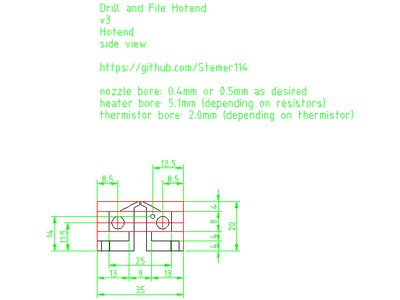

The heater block is made from aluminum alloy. It has a central bore of 5mm for housing the PTFE insulator sleeve. The central bore goes almost through to the nozzle end (minus 1.5mm). The nozzle bore (0.5mm or 0.3mm for example) is made using a hand chuck and a drill bit from the other side, so it aligns with the nozzle bore. Additionally, there are two 5mm bores for the wire-wound heating resistors and a single bore of approx. 2mm for the thermistor. At the top of the heater block there are two M4-threaded 3.2mm bores for the fixing screws.

Note that the heater block has no thread or other fixing means for the insulator. The insulator sleeve will push-fit into the central bore with the bracket pulling the heater block against the main body of the insulator. I got this idea from

Also, despite its complex shape, the heater block is made from a single rectangular 20x35x12mm piece of aluminium alloy by simply drilling, cutting and filing.

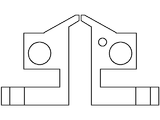

Bracket

The bracket is made of ordinary steel (Baustahl) 2mm thick by 30 mm wide. Is has two bores for the fixing screws of the heater block and two bores for the M4 rods for fixing the whole hotend to the extruder (standard distance of 50mm for fixing to extruder). In the center, there is a cutout for allowing the insulator to pass through into the heater.

Insulator

The insulator consists of two parts: an inner sleeve of PTFE with an OD of 5mm and a bore of 3mm for the filament, and a main insulator body with an OD of 15mm, which has a bore of 5mm for receiving the sleeve. The inner sleeve is approx. 18mm longer and engages with the heater block. Because of this two-part design, the insulator assembly can be made without a lathe. All that is required are two rods of PTFE round material of 5mm and 15mm OD, respectively. See the build description for an explanation on how to make a centered 3mm bore into a 5mm PTFE rod using a drill press.

The inner sleeve is inserted into the central bore of the heater block and goes all the way through to the nozzle. I got this idea from the Watson_Hot_End v0.3, where there is also a long part of the PTFE insulator engaging with the nozzle.

The lower end of the inner sleeve is pressed against the end of the 5mm bore in the heater block. The long way of the inner sleeve seems to ensure that the filament is sufficiently heated when arriving at the end of the sleeve and entering the last 2mm through the nozzle bore. The pressure comes from the bracket pulling the heater block up against the extruder, with the insulator in between. That way, there is only compression acting on the PTFE insulator, no tension or shearing.

Additionally, the 15mm main body of PTFE is pressed against the top of the heater block, thereby sealing the central bore. I have only once experienced leakage of molten filament at the top of the heater block, after I had not tightened the brackets on the rods enough. When the rods are tightened properly, there is no back leakage.

As can be seen in the picture above, the push fit design has the additional advantage of being able to swap the heater block (e.g. for using a heater block with a different nozzle diameter) of the hot end without having to heat the hot end. Because the contact of the filament with the nozzle is only minimal at the end of the PTFE inner sleeve, the heater block with the mounted bracket can be easily pulled off after the nuts on the rods have been loosened, while the insulator with the cold filament remains in place.

v3 Build Description

The heater block is made from a block of 20mmx35mm aluminium. I have bought a 182mm long bar of Al Cu Mg Pb as a surplus piece off ebay for 2.60 EUR. This aluminium alloy is excellent for drilling, milling etc. and far superior to the aluminium you can get at your local home improvement store.

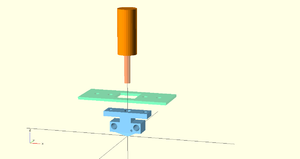

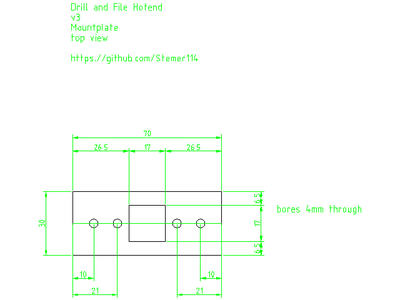

The drawing contains all the required measurements:

The bracket is made from a strip of 3mm thick, 30mm wide. I have choosen steel because it is thermally at least a little bit isolation (in comparision to aluminium). The drawing contains all the required measurements.

build process in pictures (click on them to view them bigger):

Take a 20x35mm alumium alloy bar, file the end flat and mark off 12mm. Then mark the positions of the nozzle bore and central bore on opposite sides (try to keep them aligned using a square ruler). Drill the central bore using a 5mm drill bit in the drill press. Drill almost through, but leave 2mm at the bottom.

Flip the bar and drill the nozzle bore using a hand chuck and a drill bit matching your desired nozzle size. I used cheap 0.3mm and 0.5mm drill bits (10 pcs. for 1 EUR, ebay) for this and they worked well. The drilling by hand through 2mm of aluminium takes only a few minutes. Take your time so the drill bit doesn't break.