Diamond Hotend

Release status: working

| Description | triple filament hotend

|

| License | CC-BY-NC-SA

See License section below |

| Author | |

| Contributors | |

| Based-on | |

| Categories | RepRap Diamond Hotend

|

| CAD Models | |

| External Link |

Contents

- 1 Compact multicolor printhead

- 2 Features

- 3 Benefits of this design

- 4 Sources

- 5 Assembling

- 6 Firmware adaption

- 7 Electronics setup

- 8 Slicer settings

- 9 Multi-material printing with Repetier Host

- 10 Developers

- 11 License

- 12 Revision History

- 13 Fun facts

- 14 How to get it

- 15 Mounts for other printers

- 16 Accessories

Compact multicolor printhead

Watch the video of the Prusa i3 Hephestos equipped with a Diamond Hotend printing the 3D-Hubs' mascot "Marvin" here

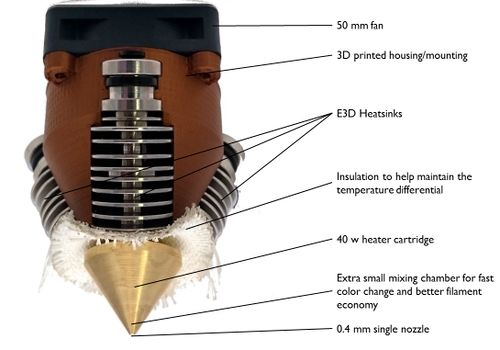

Features

- 3 pcs inputs for 1.7 mm filament

- Common 0.4 mm nozzle orifice

- Smallest possible mixing chamber for minimal waste and fast color change

- Cutout for standard 40W heater cartridge and leaded thermistor

- 3 pcs threaded mounting holes for state of the art E3D v6 HeatBreaks & HeatSinks

- Combined mounting bracket and airguide for optimal cooling by a 50mm high efficiency fan

- Optional pendant for attaching a 5015 blower fan for extrudate cooling

- Weight of assembled hotend: 250 grams (nozzle, HeatSinks, cooling shield, fan, heater cartridge & thermistor)

The key feature of The Diamond Hotend is the diamond shaped nozzle. We have designed the nozzle to have smallest possible mixing chamber, to make color shifts as fast as possible and to avoid unnecessary filament waste. To ensure rapid nozzle heat up we have constructed the nozzle as compact as possible.

Benefits of this design

- Easy calibration

- Better precision compared to multi-nozzle printing

- Prints with 3 different colors

- Minimal filament waste

Sources

These parts are recommended in order to construct a working Diamond hotend

Part list

- 1 x The Diamond Hotend nozzle File:Diamond Nozzle.pdf

- 1 x Diamond Hotend Cooler Shield (printed part)

- 3 x Thermal insulation sheet (made from lasercut fire blanket: diamond_thermal_insulation.dxf)

- 1 x Thermal compound

- 1 x Standard cartridge heater (12 Volt / 40 Watt / Ø:5.8 mm / L:20 mm max)

- 1 x Leaded glass bead thermistor (EPCOS 100k NTC)

- 3 x E3D-Lite6 HeatSinks with bowden fittings

- 1 x High efficiency fan 50 mm capable of delivering an airflow of at least 18 cubic feet per minute (e.g. Multicomp MC35357)

- 4 x Zip ties (2.5x100 mm)

- 4 x M3 x 20 mm countersunk screw [1]

- 2 x M3 x 16 mm screw

- 2 x M3 washer (Ø7 mm)

- 1 x Extension wire with 2P female Dupont for the 50 mm fan

- 1 x Heat shrink for the extension wire

Accessories

- 3 x PTFE Bowden tube (DO:4 mm / DI:2 mm /L:500 mm)

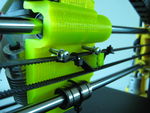

- 3 x Bowden extruder (eg. MK9 bowden extruder)

- 1 x Electronics capable of driving 6 stepper motors (eg. RUMBA)

- 1 x Radial blower fan 5015S available from eBay in both a low and a high-power version (we found that the one with a label marked AV-5015S could deliver the most output)

Assembling

Prusa i3 version

These instructions are written with Prusa i3 Hephestos in mind

If you haven't already done so, or you want the one with the blower fan option, download and print out the Diamond Hotend Cooler Shield (http://www.thingiverse.com/thing:720520). For normal use we recommend printing the cooler shield in PLA. For printing with materials that require higher printing temperatures, we recommend printing the shield in ABS or another material with a higher glass transition temperature (Tg).

Insert the two M3 nuts into the hexagonal holes at the rear of the printed Cooler Shield and press them into place. If necessary use a soldering iron to heat the nuts and melt them into place.

The two holes are spaced 30.5 mm apart, hence it should fit most Prusa i3 printers, but check with your printer anyways - you may have to customize this part if your printer have different specifications.

Apply a small amount of the thermal compound to the center hole of the Diamond Hotend.

Insert the heater cartridge into the center hole of the Diamond Hotend and press it in as much as possible. Wipe off excess compound. If there's no excess remove the heater cartridge and repeat from step 3.

Dip the thermistor tip into the remaining thermal compound and press it into the 2 mm hole in the Diamond Hotend along with some millimeters of the PTFE tubings, which will keep the thermistor locked in place.

Stack the three Thermal Isolator Sheets, feed the wire ends through their corresponding holes, then firmly press the sheets onto the Heat Breaks of the HeatSinks.

Screw the HeatSinks loosely onto the Heat Breaks. Do not tighten yet, we will do this later.

Grap the wire ends from the heater cartridge along with the thermistor wire ends and feed them all the way through the pointy end of the Cooler Shield orienting the shield in such a way that the thermistor is located closest to the Cooler Shield mounting plate. Press the small black Bowden Fittings in place.

Making sure the wires remain in the central opening of the Cooler Shield, press the shield into the hotend assembly. The rear end of the HeatSinks must click equally into the grooves on the Cooler Shield. Retighten the HeatSinks but be careful not to over-tighten or the Heat Breaks might collapse.

Use 3 cable ties to attach the HeatSinks onto the Cooler Shield and the fourth cable tie to attach the wires onto the rear part of the Cooler Shield (the side which has a groove where the cables will fit).

Cut off any excess of the cable ties.

Mount the fan using 4 pcs M3 x 20 mm countersunk screws. Make sure to orient the fan such that the airflow goes down into the Cooler Shield (label side of fan pointing into the assembly) and the wires coming out at the same side as the other wires.

Attach the hotend mount onto the carriage using 2 pcs M3 x 16 mm along with 2 pcs M3 washers.

To avoid filament clogging and/or meltdown of the Cooler Shield the fan must be constantly running. Be sure to connect it directly to 12 volt by cutting the heat shrinking tube into two pieces, sliding them over each wire (black and red) and soldering the bare leads onto the included extension cord. On a RUMBA board there is a 2 pin terminal referred to as 12V. Connect the black wire to - and the red wire to +.

Strip the outer 5 mm of the heater cartridge wire ends and mount them in the Hotend power output screw terminal. On a RUMBA board this is done via the terminal referred to as HE0. The thermistor plug goes to the pins marked T0.

Before using your Diamond Hotend, in order to avoid liquid plastic leakage the HeatSinks must be properly tightened while hot. Heat up your Diamond Hotend and tighten the HeatSinks. (While you are at it, make sure the top fan is running or you will end up with a hotend mount meltdown). You may use a water pump size pliers (to avoid making marks or scratches on the HeatSinks you could put a piece of cloth in between) but please be careful not to over-tighten as the weakest spot is the HeatBreak and it cannot take a whole lot of stress.

When connecting the Z-axis motor wiring on a printer with dual Z-motors you will find that there is only one plug on the board. A simple workaround is to strip the wires and connect then in parallel to the Z-screw terminals. Another workaround is to solder the wires into one plug. Please note the colours or the order of colours shown here is not necessarily the same as found on your printer (please refer to your printers documentation). If you find that motor(s) are turning the oppotite way as intended then simply switch off the machine, turn the plug(s) by 180 degrees and switch back on.

- Attaching the bowden tubes

See the chapter Bowden tube hints

- Done!

Congratulations! You now have an assembled Diamond Hotend.

Prusa i3 version with extrudate cooling

If you wish the benefits of actively cooling the extruded material while printing with your new Diamond Hotend (especially good for printing bridges and overhangs), we encourage you to browse to http://www.thingiverse.com/thing:720520. There you will find an alternate cooler shield file, this version features a pendant for attaching a 5015S radial blower fan.

- Download and print “diamond_cooler_shield_blower.stl”, and “bq_extruder_Tobera.stl”.

- Insert two M3 nuts into the cooler shield blower pendant.

- Screw the blower bracket in place using 2 pcs countersunk M3 x 10 mm screws.

- Screw the radial blower onto the blower bracket using 2 pcs M3 x 20 mm screws.

- Screw the blower nozzle onto the blower bracket using 1 pcs M3 x 15 mm screw.

- Extend the wires from the blower

Bowden tube hints

- Regarding the length of the bowden tubes; shorter is better because it decreases both corrugation and resulting friction. However the shortness of the bowden tubes actually depends on how far the hotend can move. Be sure to make them long enough to be able to reach all hotend positions while still avoiding any sharp bends at all.

- Using even lengths on all three tubes are easiest to manage in case you want to swap any of them at a later point.

- Roughly speaking most printers with a standard 20 x 20 cm print area (at least those with hotend moving in only one dimension having a clearance in the order of 200 mm) will need the tubes to be approximately 50 cm (depending on extruder placement).

- On Witbox (which has a print area the size of a sheet of A4 paper) the tubes need to be approximately 65 cm.

- Before inserting the bowden tube into the E3D HeatSink, cut off a small piece perpendicular the end as to make a perfect right angle cut. This should minimize any gap between the tube and the hotend and help avoid clogging.

- At the motor end of the bowden tube drill the inside of the tube using an exacto knife (or another sharp tool) in order to make a small funnel helping to guide the filament into the tube. Make absolutely sure to remove all excess drill remainings before proceeding to the next steps since you do not want this residue inside the hotend, it can make your hotend clog!

- Prior to heating and applying filament you must fully insert the bowden tubes (approx. 53 mm) into the three E3D-(Lite6) HeatSinks. If you do not, the HeatSinks will get clogged - and after cooling the filament get stuck.

- If you have a bowden tube that is stuck with melted up filament inside and you are having trouble getting it loose, take a cup of hot water (60 deg. Celcius or above) and dip the tube into it for about ten seconds. This will soften the filament and you should be able to push out the blockage with ease using another piece of filament.

Firmware adaption

For the development of this hotend we have been using the RUMBA motherboard running Marlin

The necessary firmware adaptions listed below are centered on Marlin

In Configuration.h

#define MOTHERBOARD 80 #define EXTRUDERS 3 #define TEMP_SENSOR_0 6 #define TEMP_SENSOR_1 6 #define TEMP_SENSOR_2 6

In Pins.h (scroll down into the “RUMBA pin assignment” section)

#define TEMP_0_PIN 15 #define TEMP_1_PIN 15 #define TEMP_2_PIN 15

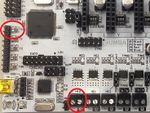

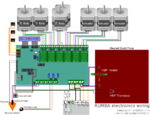

Electronics setup

Rumba

If you are using a RUMBA motherboard to control your printer, here is how to set it up for the Diamond Hotend:

- Link: Wiring of the various parts

- Install the RUMBA TAURINO driver from RUMBA (scroll down to the RUMBA_USB_Driver_for_Windows section)

- Move the on-board jumper from "Stand-alone" to "USB Power". See reference image.

- Attach a MINI-USB cable.

- If you do not already have Arduino IDE installed on your computer, download and install it from http://arduino.cc/en/Main/Software. For general info on how to upload firmware onto the motherboard please see http://arduino.cc/en/Guide/HomePage.

- Using Arduino IDE, upload the Marlin (Stable) Diamond Hotend version firmware to the motherboard. If you are using a different printer you should edit the firmware to fit your machine parameters.

- Move the jumper back to "Stand-alone" position.

- Mount stepsticks into the sockets X, Y, Z E0, E1 and E2 on the Rumba motherboard. Caution: be sure to orientate them such that the corner pin marked EN is closer to the motor output terminals.

- Attach the thermistor to the T0 pin header.

- Power supply wires (12 volt) mounts in the MAIN-PWR screw terminal.

Note: if you are using the BLUE version of the Rumba board and want to connect a display via the EXP1 and EXP2 terminals, be aware that the silk print has those two connectors swapped, so you should connect the EXP1 cable to the terminal labeled EXP2 and vice-versa.

Other

If your current electronics supports only one or two extruders but has at least 6 GPIO pins in surplus you should be able to upgrade the number of extruders.

Please see Adding more extruders.

Slicer settings

Slic3r

Print Settings tab:

Layers and perimeters → Layer height: 0.2 mm

Printer Settings tab:

General → Capabilities → Extruders: 3

Custom G-code → Start G-code:

T0 M190 S[first_layer_bed_temperature] ; Note for other slicers: "[first_layer_bed_temperature]" must be exchanged with e.g. "50". M109 S[first_layer_temperature] ; Note for other slicers: "[first_layer_temperature]" must be exchanged with e.g. "180". G28 G0 Z5 G0 X0 Y0 G91 T0 G0 E8 F100 T1 G0 E8 F100 T2 G0 E8 F100 T0 G90 G0 X30 Z0 F1000 G0 Z0.1 G92 E0

Custom G-code → End G-code

T0 M104 S0 M140 S0 G28 X0 G91 G1 Z10 F1200 M84

Extruder 1 → Size → Nozzle diameter: 0.4 mm

Extruder 1 → Position → Extruder offset: X: 0 mm

Extruder 1 → Position → Extruder offset: Y: 0 mm

Extruder 1 → Retraction → Length: 8 mm (hint: if clogging occours try lower values or increase cooling flow)

Extruder 1 → Retraction → Lift Z: 0.1 mm

Extruder 1 → Retraction → Speed: 100 mm/s

Extruder 1 → Retraction → Extra length on restart: 0 mm

Extruder 1 → Retraction when tool is disabled → Length: 8 mm (hint: if clogging occours try lower values or increase cooling flow)

Extruder 1 → Retraction when tool is disabled → Extra length on restart: 0.2 mm

(The same settings apply to extruder 2 & 3)

Alternative start code

This start gcode works very well with machines capable of fast Z-axis movements:

T0 M190 S[first_layer_bed_temperature] ; Note for other slicers: "[first_layer_bed_temperature]" must be exchanged with e.g. "50". M109 S[first_layer_temperature] ; Note for other slicers: "[first_layer_temperature]" must be exchanged with e.g. "180". G28 ; home all axes G91 ;Use relative coordinates M106 T2 G0 Z3 E20 F100 G0 Y20 Z-3 F1000 T1 G0 Z3 E20 F100 G0 Y20 Z-3 F1000 T0 G0 Z3 E20 F100 G0 Y20 Z-3 F1000 M107 G90 ;Use absolute coordinates G92 E0

Cura

At the time of writing, triple-material slicing with Cura is not recommended. We tried, but the current version (v.15.01 at the time of writing) of Cura only works for dual material printing. However the developers of Cura has mentioned that this will become a feature from the next major version change.

Other slicing software

If you prefer using slicing software that has not been mentioned here and you have successfully applied workable settings, we encourage you to share these settings with the rest of the community by uploading them to one of the free online file sharing sites. Be sure to use the name Diamond Hotend either in the title, description or tags and add it to this section.

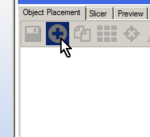

Multi-material printing with Repetier Host

Add your desired multi-material object (.amf file) using the encircled plus symbol on the right pane.

Again using the encircled plus symbol add “primetower.amf” then click the encircled areas and enter a Z-value to scale it in the Z-direction equal to the object in step 1.

Verify that the primetower is located behind the object to be printed as seen from View → Front View.

Choose Slic3r settings appropriate for the object you want to print and press “Slice with Slic3r...”.

You can now print directly from within Reptier Host or choose to save your gcode to SD-card.

The primetower.amf file is accessible for download via the link mentioned in step 1 of the assembling instructions.

For further info on using Repetier Host please refer to the Repetier-Host Documentation: http://www.repetier.com/documentation/repetier-host/

Developers

The source code for the cooling shield is an OpenSCAD script that you can download here: thingiverse thing 720520

If you are making a Diamond Hotend mounting bracket for a different printer we encourage you to share your design with the rest of the community by uploading it to one of the free online file sharing sites. Please use the name Diamond Hotend either in the title, description or tags and add a link in the bottom of this page.

License

The Diamond Nozzle is released under the Creative Commons CC-BY-NC-SA license. We chose this license because of the significant amount of man-hours invested in the project. The cooling shield and related parts that we have developed are released under the CC-BY-SA license. We intent to release the original project as a whole under the CC-BY-SA license, if and when we decide to publish a new or superior version of the project.

Revision History

Production batches:

Rev. 0.1a (2 pcs produced for proof of concept)

Rev. 0.2b (10 pcs produced for beta testing)

Rev. 1.0

Fun facts

Beginning April 1st. 2015 a Kickstarter campaign were launched to initiate the Diamond Hotend production. As of April 3rd. the campaign had reached its goal with still 27 days to go. At the end of the campaign the goal was met by over 400% of the original (DKK150000) sum pledged. A big thank you to everyone goes out to every one of the backers supporting this project by pedging in on the campaign.

How to get it

The Diamond Nozzle can be bought alone or as a Diamond Hotend kit at RepRap.me

Mounts for other printers

- Diamond hotend printrbot 2 plus 1306? edition by Enochj

- Diamond hotend Nozzle -Kossel / Delta mod. by Rhuuk

- Diamond Hotend for Rostock Max by MeowFace

- Diamond mount for Replicator/Duplicator by kharar

- Diamond hotend direct extruder by sopak

- Diamond Hotend Mount and BasePlate for Rigidbot by Michael Peters (Mykal451)

- ...

- Made a new design? Go on and list it here

Accessories

- Diamond hotend print cooler by Kulitorum

- MK9 universal Bowden mount (Based on Wanhao MK9 extruder) by kharar

- Universal RUMBA holder for i3 Hephestos by kharar

- Kuro´s Compact Extruder for the Diamond Hotend by snipermand

- ...

- Made a new design? Go on and list it here