DIY Hobbed Drive Gear

Release status: experimental

| Description | A mounting jig to make stainless steel hobbed drive gears.

|

| License | |

| Author | |

| Contributors | |

| Based-on | |

| Categories | |

| CAD Models | |

| External Link |

Introduction

I was wondering if it was possible to make a stainless steel hobbed gear drive using a M3 turning tap. Some techniques described in RepRap are based on pressing taps mounted in drilling machines against bolts, using bearings mounted in a vise to let the bolt spin. This method works reasonably well for soft iron bolts, but when I tried to replicate the method in hard stainless steel rods, the only result I got were lots of broken taps.

In this page I describe a simple mounting jig that was used successfully to make MK8 stainless steel hobbed drive gears. Besides the jig, the technique requires a lathe and a milling machine to make precision machined gears.

Overview

The standard MK8 Drive Gear have an hob diameter of 7 mm. This is the diameter of MK8 Drive Gears listed in Drive-gear and manufactured by Aus3D, RepRap.me, TaoTac.com and Twelvepro.com. Others manufactures offer a diameter of 7.25 mm (Garage Days 3D and Alfa-Tech3D) or 7.1 mm (TriDPrinting.com).

Perhaps the last option has an actual hobbed diameter slightly greater than 7 mm to consider the bite of the teeth, but 7.25 mm is a diameter too large to be explained by the bite. To make things worse, the manufactures does not specify if this diameter is the major or minor diameter of the gear thread.

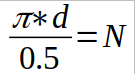

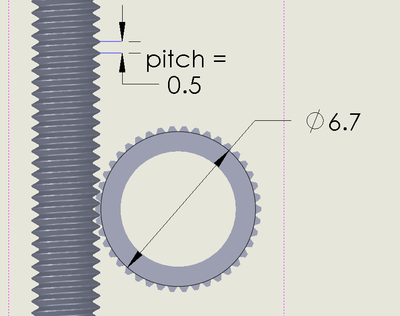

There is some uncertainty about the optimal number of cuts on the gear's circumference and due to the reason explained before, I preferred to calculate the diameter gear from scratch. For this, lets consider that a M3 tap has an major diameter of almost 3 mm and a pitch equal to 0.5 mm. The number of cuts on the gear internal circumference must be a multiple N of 0.5 mm. If the internal diameter of the gear’s thread is d, we have:

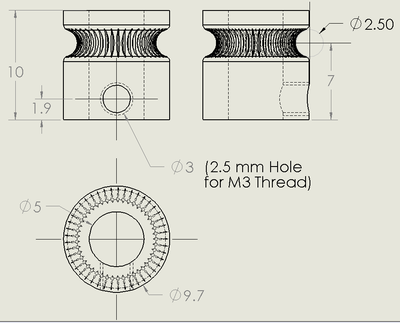

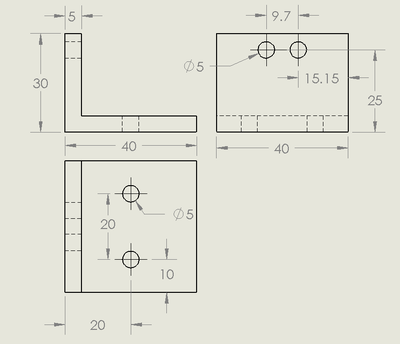

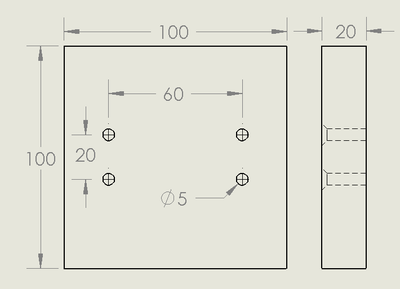

So, for a diameter d = 6.7 mm, we obtain an N equal to 42 cuts as shown in figure 1. Considering a thread high equal to 0.25 mm, the outer diameter of the gear’s thread will be 6.7 + 2*0.25 = 7.2 mm. As the hole required to tap an M3 thread is 2.5 mm, the total diameter of the gear will be 7.2 + 2.5 = 9.7 mm. Figure 2 gives the gear dimensions that will be made in next sections.

- Making Grooved Gears

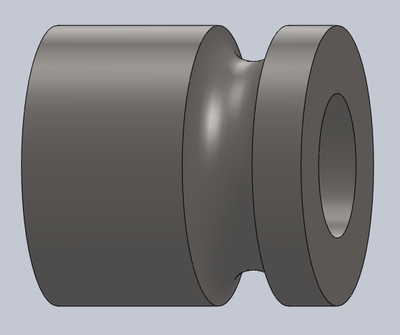

With the necessary gear dimensions established, a lathe is used to turn a stainless steel rod to make several bored grooved gears as shown in figure 3. The lathe operations required are straightforward and can be seen in detail in the video at the end of the page. Figure 4 shows some grooved gears to be hobbed in next steps.

- The Jig

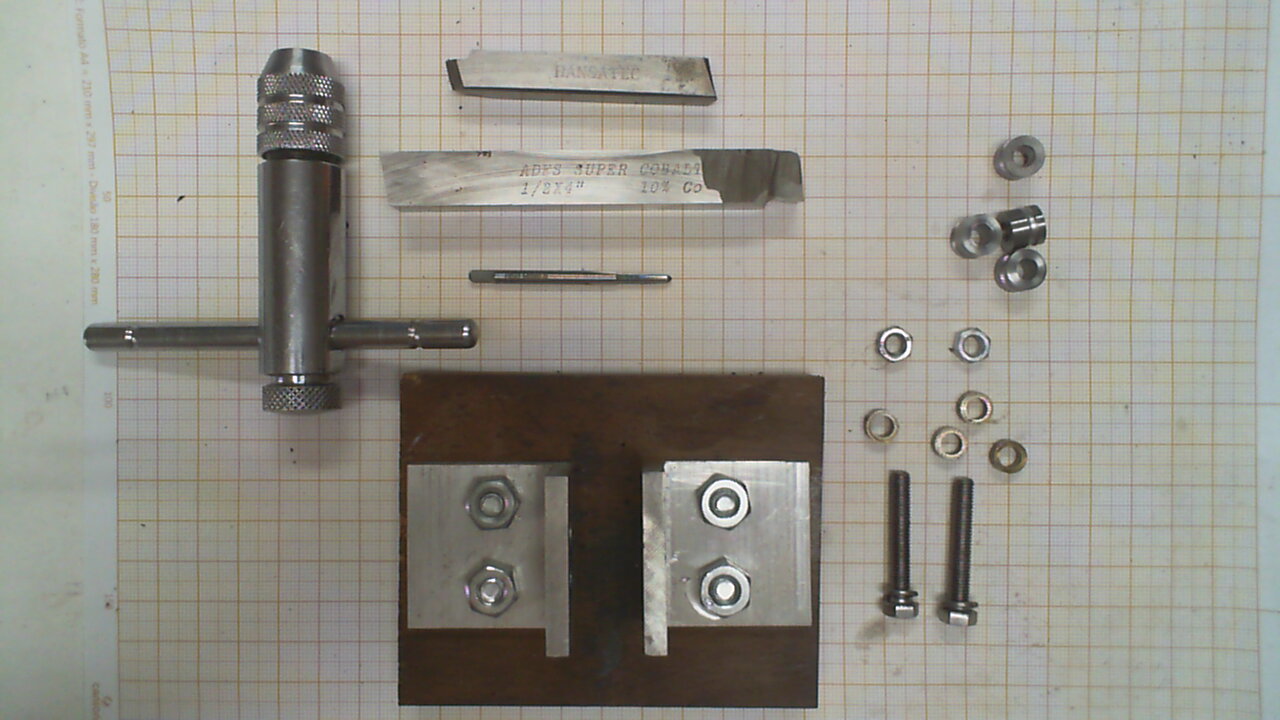

Figures 5 and 6 show a technical drawing of the main parts of the jig used to hobbing the gears grooves. They can be produced in a mill with L shaped aluminium profile and plywood. The most important measure is the distance of 9.7 mm for the two M5 screws that will support the gears. This distance needs to be precisely set in order to make sure that the two gears are perfectly tangent, without gaps. Among these parts, it is required four flat-head M5 x 25mm screws, two hex-head M5 x 35 mm screws, six M5 nuts and two brass washers to keep the gears constrained between the L shaped aluminium supports.

- Material for hobbing

Figure 7 shows the required material for hobbing. Among the jig itself, with its screws and nuts, we need an M3 Tap and two hard steel bits.