Crispy HotEnd

Contents

A Bit of Background

This HotEnd was developed after struggling with the fact that in Argentina (were I live) PEEK is very hard to come by, very expensive and a controlled material (since it can be used to manufacture guns).

Therefore, I went and designed a PEEK-free HotEnd.

Since PTFE is available and fairly cheap, I started to work on building a HotEnd based on that insulation.

PTFE is easy to work with, threads don't last much and are quite fragile, to solve this I went on and designed a "contained" PTFE insulation.

I took some ideas from the Budaschnozzle (which I tried, unsuccessfully, to build replacing PEEK with PTFE)

I'm a Hobbyist Lathe operator, so a lot is done on my lathe. That's a lot of help and makes this cheap.

I Hope some people out there find it useful.

Gustavo "Crispy" Blanco

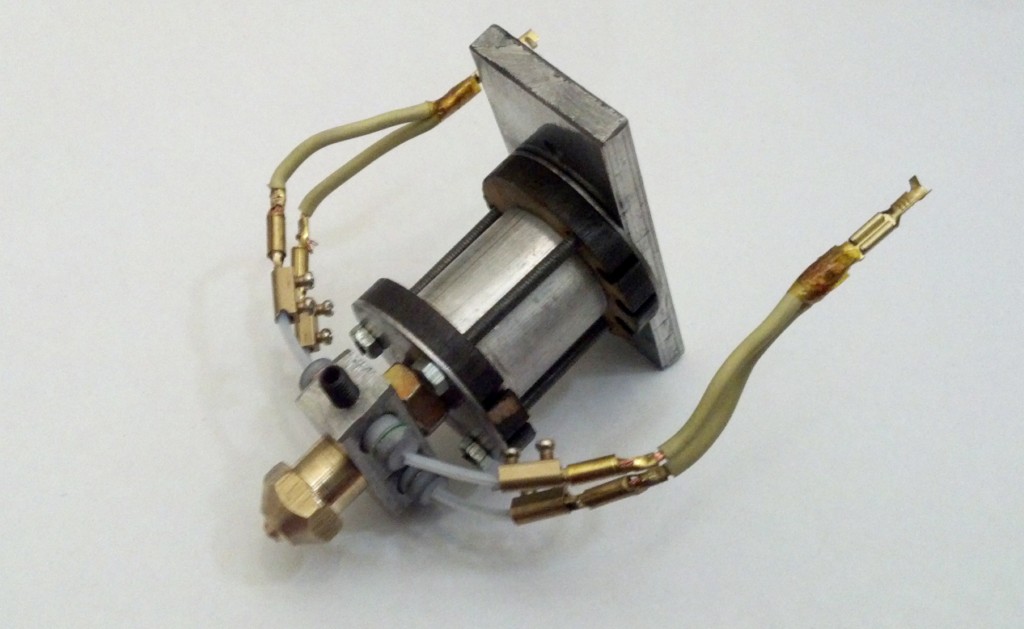

The Crispy HotEnd

The HotEnd Disassembled

BOM (Build of Materials)

1 * 50 mm Long 12mm Aluminium Round Bar (Barrel) 1 * 20 mm Long 12mm Brass Hexagonal Bar (Nozzle) 1 * 12 mm Long 12mm PTFE Round Bar (Inner Insulator) 1 * 25 mm Long 1" or 25mm PTFE Round Bar (Outer Insulator) 1 * 25 mm Long 1" or 25mm Aluminum Pipe (Shield) 2 * M8 Large Washers 2 * Pieces of MDF 5.5mm thick (use the large Washers as a template) 1 * M8 Nut 1 * 6mm x 32mm x 80mm Aluminium square bar 3 * 1/8" x 50mm Bolts 3 * 1/8" nuts

The Built

Tipically I star with the Barrel.

It's a 50mm 12mm Aluminum round bar which it turn to 8mm in diameter for 45mm, and make those 45 mm a 8x1.25 Thread.

Next, I take a piece of 1" (or 25mm) Aluminum Pipe and cut a 25mm long section. On the Lathe and with a piece o 25mm PTFE, turn it so you can fill the pipe (try to get it tight). With a 6.75mm Drill bit, drill the PTFE (at least 30mm deep). Then with a 12mm Drill bit, drill 18mm into the PTFE

Now take a