Calibration/fr

|

English • العربية • български • català • čeština • Deutsch • Ελληνικά • español • فارسی • français • hrvatski • magyar • italiano • română • 日本語 • 한국어 • lietuvių • Nederlands • norsk • polski • português • русский • Türkçe • українська • 中文(中国大陆) • 中文(台灣) • עברית • azərbaycanca • |

Votre RepRap fonctionne bien ? Génial !

Avez-vous déjà eu un pied à coulisse pour vérifier si ces 10 mm dans le fichier STL correspondent à ceux de la pièce imprimée ? Si le trou de 8 mm a vraiment 8,0 mm de diamètre, ni 6,8, ni 8,3 ? Non ?

Cette page a pour but de vous remonter le moral au cas où vous ou votre copain soyez déjà déçu. Une Reprap peut être calibrée aussi précisèment que sa mécanique le lui permet.

Contents

- 1 Pré-requis

- 2 Théorie et Maths

- 3 Further reading

- 4 References

- 5 Old Version of this Page

Pré-requis

Avant de commencer la calibration, il faut que la construction de votre machine soit déjà bien avancée de sorte qu'elle soit pas mal stable.

Une fois que la construction physique de votre imprimante 3D est finie, il s'agit du nouveau gros morceau.

Si vous essayez d'imprimer avant la calibration, vous obtiendrez vraisemblablement un enchevètrement de plastoc qui barbouille le plateau de votre imprimante.

En utilisant la procédure de calibration suivante, je suis passé d'un amas immonde à de belles pièces imprimées en une seule journée. On pourrait croire que c'est de la magie.

Les objets et informations de cette page proviennent (et ont été publiées) de Coasterman qui les a postés sur Thingiverse.

Je les ai déplacés sur le wiki de RepRap afin que la communauté puissent les édités et les amender plus facilement. Aussi si vous avez une idée ou un objet qui puisse aider à faciliter cette calibration, n'hésitez pas à rajouter l'information ici.

Les recommandations particulières de cet article sont basées sur Skeinforge (ou Sfact) cependant vous devriez trouver les paramètres équivalents dans votre programme préféré. ¢n dehors du logiciel que vous employez, vous devriez trouver ce jeu d'instructions de calibration fort utile.

D'une manière générale, vous devriez lancer ces test de calibration pour ajuster votre imprimante au programme que vous utilisez. Une fois fait, je vous recommande de procéder à un second test car le dernier peut affecter les précédents.

Mise à niveau du plateau

Objectif : Ajuster la hauteur du plateau afin que vos objets adhèrent à la surface.

Pièce à imprimer pour tester la mise à niveau : bedleveling.stl

Avant de faire quoi que ce soit, vous devez mettre à niveau votre plateau. Il ne sert absolument à rien d'imprimer tant que le plateau n'est pas parfaitement de niveau et à la bonne hauteur. Lors d'une impression, la première couche est la fondation de toutes les suivantes, si la première passe n'est pas nette et qu'elle n'adhère pas bien vous n'avez plus qu'à stopper l'impression et corriger ce problème.

Instructions

Lisez et complétez la page sur la mise à niveau du plateau avant de passer à l'étape suivante.

Une fois le plateau de niveau, imprimez la pièce de test de niveau du plateau et assurez-vous que chaque coin est à angle droit, lisse et régulier. Il est possible que vous deviez télécharger le fichier scad original de cette pièce afin de la faire correspondre aux dimensions de votre plateau : http://www.thingiverse.com/thing:13053

Préparation de la surface du plateau

Objectif : préparation correcte du plateau pour être certain que les objets y adhèreront.

Instructions

Un plateau mal préparé peut être la cause d'une faible adhérence du plastique dessus mais aussi d'un effet de 'bubbling'. Il suffit même parfois d'un peu de graisse laissée par les doigts pour ruiner une impression.

La préparation du plateau dépendra du matériau dans lequel il est fabriqué :

Pour du verre

Nettoyer le verre avec un nettoyant classique pour les vitres de la maison et un chiffon qui ne peluche pas. Ne ménager pas vos efforts pour rendre le verre impeccable.

Matériau différent du verre

TODO: Cette section a besoin d'être enrichie.

Le Kapton est un ruban adhésif résistant à la chaleur qui est couramment utilisé pour recouvrir les plateaux quelle que soit sa matière. Le Kapton offre une bonne adhérence pour une grande variété de plastiques.

Calibration des moteurs

Objective: set the current for the stepper motors to the correct level.

Your motors should be quiet when running and can occasionally make musical sounds, particularly when making circles. If they are making a fair amount of noise then you have a problem.

Calibration Object: None

NOTE: incorrect current settings can damage your pololus and/or your motors.

Symptômes

Motors make significant noise.

This generally means you have too much current.

Motor vibrates on the spot.

This generally means that you don't have sufficient current to the motors. You could also have a problem with a part sticking which stops the motor from being able to drive the axis.

Axis movement pauses momentarily and then resumes.

You may have too much current going to the motor which is causing the pololu to over-heat. Reduce the current. This can also be caused by firmware but check your motors first.

Instructions

Each Pololu has a trimpot located next to the heatsink. The trimpot controls the current that is sent to each motor. Turning the trimpot counter-clockwise reduces the current to the motor, turning it clockwise increases the current to the motor.

Start by adjusting the trimpot down until your motor vibrates on the spot rather than turning cleanly. Now turn the trimpot in a clockwise direction in small increments (1 eighth of a turn) until the motors just start running. Then give the trim port a final turn of about 1 eighth of a turn and your should be good to go.

Extrusion

Objective: to ensure the hot end temperate is set correctly so that material is extruded cleanly

Calibration Object: None

PLA

Layer height

Objective: to correct the layer height settings to reflect your printers actual layer height.

Calibration Object: 0.5mm-thin-wall.stl

Instructions

Print the 0.5mm thin wall cube and make sure that the layers adhere well but the nozzle does NOT drag through while printing.

Adjust softwares layer height in .01 increments until you get a nice print.

Depending on other factors you may find it hard to get all four walls to print nicely. For the first pass if you can get just one wall looking good then move on to the next test.

Infill

Objective: to correct the infill setting.

Calibration Object: 20mm-box.stl

Instructions

Set infill solidity to 1.0 for this.

Print the cube and analyze the top. If there is NOT ENOUGH plastic (a concave top), reduce the Infill Width over Thickness by .05 increments. If there is TOO MUCH plastic (convex top), turn that parameter up by .05 increments.

Once you're feeling close, start bumping it around in smaller increments.

You may also need to adjust your feed rate.

Adjust the feed rate by increments of 2 or so until you feel close. If it looks really disgusting and blobby, go by increments of 0.5mm. Then go by smaller and smaller increments until you've nailed it. Although you probably just want to decrease Infill Width over Thickness instead of decreasing Feedrate because lowering feedrate will degrade the resolution.

Temperature control

Objective: to set the hot end temperature correct for your preferred plastic.

Note: you will find that different types of plastic have vastly different temperatures for both your hotend and your bed. What you might not expect is that different colours for the same material can also required different printing temperatures.

As the tower has quite a small 'top' surface area you may need to cool this object as you print. If your printer doesn't have a built in fan you can use any room fan as a substitute.

Calibration Object: 50mm-tower.stl

Instructions

Set the 'Infill solidity' to 100%.

Start by doing a simple extruder test to determine what the range of temperatures are that you can extrude at. Reduce the temperature in 5 degree increments until the extruder starts skipping when you do a manual extrude. Turn the extruder up 5 degrees and note this as your minimum extruder temperature.

Print this block.

If it looks like a blob, turn down all the temps by 5 degrees until you get something good. Chances are you won't need to do this more than 5 degrees.

Note: Be careful as going too low can result in the plastic setting making it hard for the motors to drive the plastic, possibly causing wear or damage.

TODO: list temperature ranges for common plastics.

Recommendations

PLA

Hotend: 185

Bed: 60

ABS Hotend: 230

Bed: 110

Perimeter Width

Objective: correct the perimeter width over thickness

Calibration Object: perimeter-wt.stl

Instructions

This test prints two objects which are designed to fit together.

Try to insert the smaller block into the larger block. Try inserting it differently a few times, and check your belt tensions.

TODO: Need notes on calibration of belt tensions

If you can get it in a few mm, good. If you can get it in all the way, awesome. The fit should be snug. If it is loose and can jitter around inside, decrease the perimeter width over thickness. If you CANNOT get it in AT ALL, and you are sure there are no whiskers blocking it, INCREASE perimeter width over thickness. The latter is more likely.

Bridging

Objective: to maximize your printers ability to bridge gaps (i.e. print in thin air).

Calibration Object: 20mm-hollow-box.stl

Instructions

Print the calibration object and if the top droops in, increase the BRIDGE FEEDRATE MULTIPLIER in Speed by increments of .1 until the top stops drooping.

Print Precision

Objective: improve print precision

Calibration Object: precision-block.stl

Instructions

Then there is the precision block. No real huge calibration parameter here. Just play with this and see how well it does on the overhangs and shapes.

TODO: We need to add some recommendations on how to improve this or find more direct methods of calibrating specific aspects of the print.

Overhang

Objective: fix overhang problems

Calibration Object: overhang-test.stl

Instructions

Then there is a simple overhang test. Print and observe the overhangs. This is up to you to figure how to improve the overhangs.

TODO: We need to add some recommendations on how to improve this or find more direct methods of calibrating specific aspects of the print.

Oozebane

Objective: stop material oozing out of the noozle during 'non-printing' moves.

Many extruders will emit (ooze) plastic even when the extruder motor is not turning. To overcome this your slicing software needs to 'retract' the print medium during head movement when not printing. The retraction creates negative pressure within the hot end heating chamber which effectively sucks the print medium back up through the nozzle, stopping it from oozing.

Calibration Object: oozebane-test.stl

The calibration object prints two towers about 30 mm apart. The head must move between each of the towers at each layer. If your printer is not set correctly then you will see many fine filaments (or strings) between the two towers. You can eliminate these filaments by eliminating ooze.

Symptoms

Instructions

This is to try to control ooze and calibrate it to be useful.

Start by setting the Early Shutdown distance to 0 and Slowdown Startup Steps to 1.

Print the piece and measure the length of stringers where the extruder shut off and the line is thick before becoming a thin whisker. Take that length and put it into early shutdown distance.

Play with Early Startup Distance Constant until the place where the extruder arrives at the other tower is nice and smooth, so that there isn't any empty space where plastic should be, but there isn't excess plastic extruded.

Parties en saillie

Objectif : éliminer l’affaissement des parties en saillie.

Pièce de test pour la calibration : BridgeTestPart.stl

Les parties en saillie (ou en surplomb) sont des parties dont les couches de plastiques ne s'appuient pas sous celle de dessous.

Instructions

Si la pièce de test s'affaisse, vous devrez certainement diminuer la valeur de "Bridge Flowrate over Operating Flowrate." Ou augmenter le "Bridge Feedrate over Operating Feedrate."

X & Y scaling

To be defined. Scaling goes into the STEPS_PER_MM of the firmware, track offset goes into the G-code compiler (Skeinforge etc.).

OK, here we get a bit stuck. While the theory section below nicely shows how to calculate the optimum track offset, Skeinforge has no configuration option to adjust this value.

- An excerpt from a chat between Greg Frost and Traumflug, on 2011/22/06:

- [14:30] <GregFrost_> I calibrated the extruded length and then set feed=flow and pw/t and iw/t to 1.5 and immediately got nice looking prints. However, and here is the kicker, the objects are all slightly too big because my single wall box has an actual w/t of 2.1

- [14:31] <GregFrost_> I can fix this with p flow but then i get thin preimeters and they dont alway bond well to each other (but objects are the right size).

- [14:31] <GregFrost_> I would like normal flow on the perim but a wider w/t but if i do that it adjusts all of the flows up and I get far too much plastic.

- [14:32] <GregFrost_> what I really need is a way to change the distance inside the objest that the perimeter is traced without changing the flow rates.

- [14:37] <Traumflug> To be honest, I never used Skeinforge, this adjustable track offset is an assumption.

- [14:38] <GregFrost_> Traumflug: it would be a good setting, i agree.

- [14:38] <GregFrost_> Traumflug: I think the only way to achieve a track offset is to adjust the perimiter w/t ratio.

- [14:38] <Traumflug> So, Skeinforge doesn't compensate for track width?

- [14:38] <GregFrost_> Traumflug: it does. but it uses the perimiter witdth/t and infill w.t settings

- [14:39] <GregFrost_> Traumflug: then it uses the layer height

- [14:39] <GregFrost_> Traumflug: and useing those it works out the track offset.

- [14:39] <Traumflug> ok, good to know.

- [14:39] <GregFrost_> Traumflug: but the kicker is, changing perimeter w/t also adjusts the flow rate

- [14:40] <GregFrost_> Traumflug: so theoretically when you choose a new w/t, it puts out enuf plastic to fill the width.

- [14:40] <Traumflug> Yes, theoretically

- [14:41] <GregFrost_> Traumflug: but on the perimiter if you use the same volumetric flow as the infill, it bulges past the desired width because there is no containing line.

- [14:42] <GregFrost_> but the one setting that allows you to compensate for that adjusts the flow on all other lines (both infill and permiiters)

- [14:42] <Traumflug> IMHO, changing the plastic flow to compensate for size errors isn't a good way.

- [14:43] <GregFrost_> Traumflug: I agree completely.

- [14:43] <Traumflug> Each time you change the flow, a lot of minor parameters change as well, so a prediction is very difficult.

- [14:43] <GregFrost_> I want to change the track offset.

Théorie et Maths

Par Markus "Traumflug" Hitter.

Axes X et Y

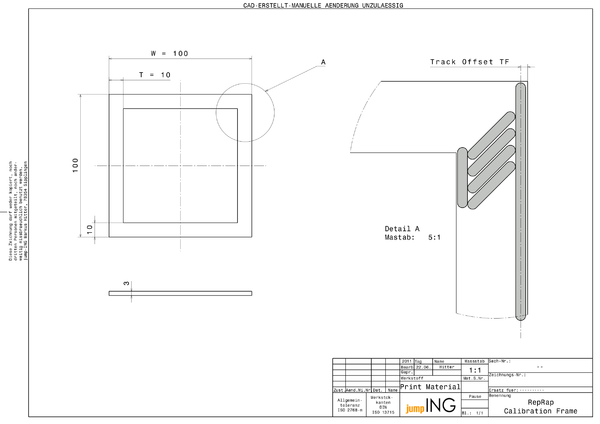

Les 2 axes horizontaux doivent être calibrés en tenant compte de 2 valeurs : le track offset (décalage en largeur dû à l'épaisseur du trait) et l'overall scaling (mise à l'échelle globale sur la longueur du trait). Pour comprendre comment cela fonctionne, regardons le schéma ci-dessous :

C'est un cadre, identiques à ceux que l'on utilise pour mettre des photos sur les murs. L'essentiel ici est de mesurer à la fois les distances longues et courtes sur une même partie. Il faut mesurer les 2 pour pouvoir faire la distinction entre le track offset et l'overall scaling.

À droite du schéma, on a esquissé quelques bandes déposées par l'extrudeur. Elles montrent comment le track offset fait que l'extrudeur se déplace très près du bord intérieur de la pièce, et que le côté extérieur de la bande s'arrête là où la pièce devait aussi arriver.

Toutes les dimensions sont touchées par la mise à l'échelle, qui est une sorte de "rapport de vitesse" entre les unités de mesure et les pas des moteurs.

Calibration Object

OpenSCAD

// X-Y Calibration object

// See http://reprap.org/wiki/Calibration#Theory_and_Maths

difference() {

cube([100,100,3], true);

cube([80,80,3.1], true);

}

STL file

Basic Equation

With that knowledge, we can sum up what the extruder moves to get the size T = 10 mm exactly 10 mm wide:

- <math>\begin{align}

\mbox{movement} = ( \mbox{intended size} - 2 * \mbox{track offset} ) * \mbox{scaling} \\ \end{align}</math>

This holds true for measurements of any size, i.e. also for the 100 mm size of our calibration frame:

- <math>\begin{align}

M_{10} & = ( 10\,\mbox{mm} - 2 * TF ) * S \\ M_{100} & = ( 100\,\mbox{mm} - 2 * TF ) * S \\ \end{align}</math>

You see? Two unknowns and two equations, so the set is solvable.

Extending to Erroneous Movements

Now, the whole point of this writing is, the extruder movement doesn't match what we need to get accurately sized parts. So we have not only a movement, but also a movement error.

Reason for the movement error is, according to the basic equitation, erroneous track offset and/or erroneous scaling.

Get these two into the basic equitation, result to the left, reason to the right:

- <math>\begin{align}

& \mbox{movement} * \mbox{movement error} = \\ & ( \mbox{intended size} - 2 * \mbox{track offset} * \mbox{track offset error} * \mbox{scaling} * \mbox{scaling error} \\ \end{align}</math>

Again, this holds true for both our measurements:

- <math>\begin{align}

M_{10} * E_{M10} & = ( 10\,\mbox{mm} - 2 * TF * E_{TF} ) * S * E_S \\ M_{100} * E_{M100} & = ( 100\,\mbox{mm} - 2 * TF * E_{TF} ) * S * E_S \\ \end{align}</math>

... to be continued ... about a formula to get scaling and track offset from measuring these 10 mm and 100 mm ...

Axe Z

Sur l'axe Z, il n'y a pas à compenser le track offset, aussi la calibration se limite à la mise à l'échelle de la hauteur d'une pièce.

Imprimez une pièce quelconque de 50 mm de hauteur, laissez-la refroidir puis mesurez-la. Ensuite ajustez la valeur de STEPS_PER_MM (ou STEPS_PER_M comme dans Teacup) dans le config.h de votre firmware afin de réduire la différence entre la pièce voulue au départ et celle obtenue en réalité. Comme beaucoup de RepRaps utilisent des tiges filetées pour l'axe Z, la valeur théorique devrait être très proche de la réalité.

N'oubliez pas aussi le retrécissement du plastique dû à la différence de température entre celle élevée de l'impression et celle ambiante.

Further reading

References

- nopheads blog on undersized holes and how to make then accurate.

Old Version of this Page

put here as the new part is still incomplete --Traumflug 22:55, 21 June 2011 (UTC)

Is this part of commissioning? Is this part of Builders/Config/Config Axes?

To calibrate, you will need the following: a Rep(st)rap, a slide caliper, and printing material (ABS, PLA, HDPE, etc).

You will also need this object file to print out.

- Setup and load your printing material.

- Print the calibration object.

- Allow the object to cool.

- Use the slide caliper to measure each edge and the diagonals.

- Make a note of each measurement and this will allow you to determine where a problem is IF there is a problem.

With the above measurements, you should be able to determine any alignment issues. The sides should measure withing .5mm of 40mm.

if it is off consistently, then it is probably a firmware issue.

Most inconsistent discrepancies are a sign of backlash (i.e. slop or play in your mechanical system). Make sure the grub screws on the pulleys are tight; make sure the belts are tensioned so that when you turn the stepper by hand, it immediately produces a movement in the axis; make sure all the bearings turn smoothly, and that the carriages only move along their intended axis. with all of that double checked, try printing your test piece again, and pay very close attention while it is printing. If your stepper motors make strange noises occasionally, it might be that they are skipping steps because they don't have enough torque. Try turning up the trim pot for that axis.

If all this fails, the best place to go to figure out how to fix your issue, once you've identified it, is either to ask someone in the forums, or on IRC, if you prefer. Then come back here and make this page better, or complain to the forum users.

Once you get a simple cube printed adequately, you might consider trying a more difficult object such as the bearing clip 01 for more fine-tuning.