Build a reprap

Contents

This page has not been checked and may well not be accurate

Build a RepRap

There are multiple ways to build a RepRap or RepStrap; the method selected for these instructions has been chosen to minimize skills and tools needed. If you wish to explore other options click Build a RepRap-Advanced

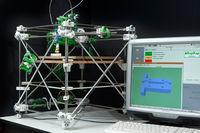

The Classic RepRap Design is "Darwin" pictured on the right. There are very full and accurate building instructions in Make Your Own RepRap.

The RepRap was carefully designed to use only parts that can be made on a RepRap and other cheap parts that you can get anywere. It was also designed to require few skills to assemble. The one snag is you have to find someone to supply you with the parts that must be made on a RepRap

RepStrap Darwin Clones are reprap designs which are fairly accurately copies of the darwin design but the RepRapped parts are replaced by parts created some other way, Perhaps moulded plastic or laser cut acrylic or plywood. Generally parts of one of these machines are interchangeable with RepRapped Darwin parts.

Other RepStraps, these are 3D printers capable of making RepRap (Darwin) parts but are not structuraly similar to Darwin. These machines may vary a lot but generally they may be separated into two kinds. Those like Darwin in which the extruder (print head) is moved in the x and y directions and the work is slowly lowered as the print progresses and others where the work is moved in the x and y directions under a stationary head which gradually moves upwards as the print progresses.

Overview

A RepRap or RepStrap (A RepRap can build itself, a RepStrap can build something that can build itself) can be divided into several key areas:

- Object creation Software

- System control Software

- Thermoplastic extruder

- Positioning system

- The electronics to control the positioning system

Object Creation Software

Art of Illusion is currently the software bundled in the Linux distribution liveCD for the RepRap project. This program allows you, the user, to view, manipulate, edit, and save STL files.

STL files are object files that are used in Rapid Prototyping. RepRap uses these files and any object you want to print must first be saved in an STL file format.

System control Software

Where to get and how to run the Java client program

Thermoplast extruder

There three different extruders all of which in the end perform the same function. There is the "official" extruder that can be made my another RepRap. Then there are the kits which are mass produced so that it is easier to start printing your first parts. Both kits are designed to be interchangeable with official extruder.

- RepRapable Thermoplast Extuder

Can be made either by another RepRap or commercial rapid prototyper. These are not the only way the parts can be made but are the easiest. Some builder have made them from machining aluminum or plastic. Other by making molds and casting from resin. This is only for the main pieces of the extruder. The drive screw and other mechanic must be bought or machined. - Kit from Bits from Bytes (laser cut acrylic)

A there is an extruder kit currently available from Bits from Bytes who are based in the UK. The kit is part of the silver or gold kits and so doesn't need ordering separately unless you want a spare. Assembly instructions are available on the bits from bytes website in the 'Assembly Instructions' area:

Bits from Bytes Extruder Assembly instructions

Bits from Bytes Extruder 3d Model - the model requires a recent copy of Adobe Acrobat.

There are also videos of the construction process, in the 'Tutorials' section of the website.

Bits from Bytes Heater Barrel Assembly

Bits from Bytes Extruder Drive Assembly

- Kit from Ponoko (laser cut plywood)

A kit will also shortly be available via Ponoko who have offices in the US.

Positioning system

Kits are available from Bits from Bytes, either the FULL Mechanical Kit - Silver or Gold contain all the components necessary to build a positioning system and extruder. Assembly instructions are available on the bits from bytes website in the 'Assembly Instructions' area:

Bits from Bytes Assembly Instructions

The electronics to control the positioning system

No pre-assembled option is currently available for the electronics and so you, or someone you know, will need to solder the components to the board.

The RepRap Research Foundation produces kits for the electronic components. The Complete Arduino Electronics Kit when ordered with the optional Aurduino and usb cable contains all the electronics, in component form, provides everything required to control the positioning system. The main RepRap site contains guides to constructing each of the boards the kit contains:

shopping list

The following list contains all the components necessary to build a RepStrap and enough plastic to print a RepRap. Some handtools are required for assembly, but the only power tool used is a soldering iron.

Extruder and Positioning System

Bits from Bytes - FULL Mechanical Kit - Silver or Gold

Ponoko - coming soon

(only one required)

Electronics

RRRF Complete Arduino Electronics Kit, Arduino Diecimilia, USB cable

Plastic

The extruders all use 3mm diameter plastic filament/wire. ABS is the recommended plastic for its combination of strength, availability and dimensional stability. Suitable plastic is available from RRRF in 5lb reels. It is also available by request from plasticweldingrod.com.

Total

Shipping and tax vary by country of order but $1000 total is a reasonable approximation.