Adapto

Release status: working

| Description | Adapto is a 3D printer that can be built with many different types of frames and frame materials.

|

| License | GPL

|

| Author | |

| Contributors | |

| Based-on | |

| Categories | |

| CAD Models | |

| External Link |

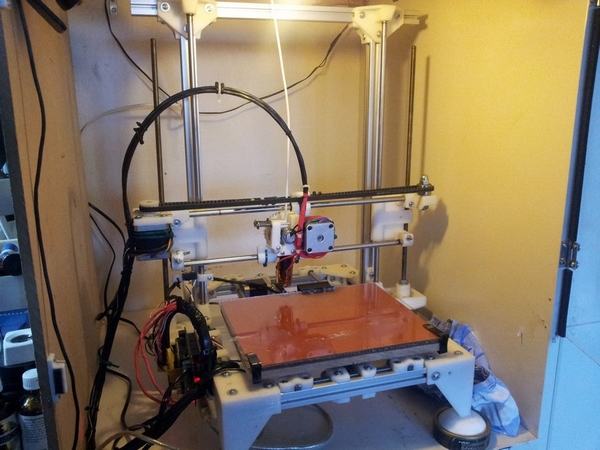

The ADAPTO!!

The thought behind the Adapto 3D printer is that one can use the same printed parts on printers with different types of materials (in the frame).

The history behind this design is that i got hold of some alu extrusions that was intended to be used on a MendelMax. During the MM build i got so extremely annoyed with how over engineered it is so I decided to tear the MM apart in favor to make a design that only used 50% of the MM extrusions (that means i now have enough extrusions for 2 printers :D ).

I also designed the parts in a way that makes the builder able to use either Alu extrusions (20x20mm), wood, alu, acryl plates or plates made out of any material actually (if it is stiff enough).

I recommend not using anything thicker than 20mm thick plates/stripes (due to the y motor mount and y idler parts) and use max 34mm wide frame parts (due to the design of the feets), but thinner is ok if the material is stiff enough.

More information

This is also posted on:

- GitHub: https://github.com/rotorit/Adapto

- Thingiverse: http://www.thingiverse.com/thing:29850

The most up to date Files will always be on GitHub.

- Sample BOM for a Big T-Slot Adapto: the BOM page lists required parts, gives sample sources, and discusses possible alternatives

ENJOY!

This is such an easy build it dont need much instructions.

- Print the parts

- choose your frame material

- look at the pictures

- BUILD IT! :D

Thanks to the entire RepRap- and Thingiverse- comunity for all the inspiration.

All the pictures can be viewed and downloaded from Thingiverse and GitHub

The Wooden frame is just an example of what you CAN use for frame material. Open your mind and let the creativity flow! :D

If you decide to build one, please feel free to add a pin on the Adapto map.

_________________________________________________________________________________________________________________________________

RP parts

This is the RP parts you need to build a 20x20mm alu extrusion framed Adapto with 8mm smooth rods, M5 Z-threaded rods and makes a 200x240mm build area with a Z travel up to about 270mm

So if you have a MendelMax frame laying around you can build 2 of this Adapto 3D printer :-)

This table is still under construction and is not yet complete.

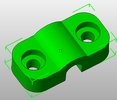

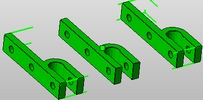

| Quantity | Part Name | Part Type | Used Where | Comment | Looks like | File Download | 4 |

Y_Rod_Clamp_4_Off.stl |

RP | Frame | Holds the Y smooth rods firmly to the frame. You need 4 of these for each Adapto printer you build | [1]GitHub,

[2]Direct |

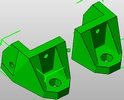

1 |

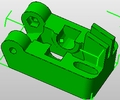

Y_Motor_Mount_1_Off.stl |

RP | Frame | Holds the Y motor to the frame. Fits a Nema 17 stepper motor just fine. You need 1 of this for each Adapto printer you build | [3]GitHub,

[4]Direct |

1 |

Y_Idler_1_Off.stl |

RP | Frame | This is the Y axes belt idler that holds the Y belt idler bearing(s) firmly to the frame. You need to print 1 of this .stl file (that actually contains 2 plastic parts) for each Adapto printer you build. | [5]GitHub,

[6]Direct |

1 |

Y_Belt_Block_1_Off.stl |

RP | Bed | This part is to be mounted under the bed. It holds both ends of the Y belt firmly to the bed making the stepper able to move the Y akses. The belt can for example be mounted to this with Zipties and make you able to get the belt nice and tight. You need one of this for each Adapto printer you build. | [7]GitHub,

[8]Direct |

3 |

Y_Bearing_Holder_LM8UU_3_Off.stl |

RP | Bed | Holds the Y axes bearings that slide on the Y smooth rods. Is to be mounted under the bed and holds a firm grasp on the y linear bearings of choice as long as the bearings have a outer diameter of about 15mm. You need at least 3 of these on each Adapto printer you build. Some people prefer to use 4. | [9]GitHub,

[10]Direct |

2 |

Z_Motor_Holder_2_Off.stl |

RP | Frame | Holds the Z motors firmly to the frame. You need 2 of this for each Adapto you build. | [11]GitHub,

[12]Direct |

1 |

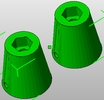

Z_Couplers_M5.stl |

RP | Z Motors | Couples the Z threaded rods firmly to the Z motors. You need to print 1 of this .stl file (that actually contains 2 plastic parts) for each Adapto printer you build. | [13]GitHub,

[14]Direct |

4 |

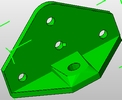

Foot_4_Off.stl |

RP | Frame | Holds the lower frame firmly assembled and also work as the feet clearing the Z motors from the table keeping the nice look intact. You need 4 of these for each Adapto printer you build. | [15]GitHub,

[16]Direct |

2-10 |

90_innerCorner.stl |

RP | Frame | Primary to support the frame on the opposite side of the extrusion from the Z_Smooth_Rod_Holder_Lower_2_Off.stl helps to keep the high frame at 90 degrees onto the lower frame. Recommended is to also use 4 more supporting the high frame in x direction. Some people also prefer to use even 4 more of these on the inside corner on the back side of the feet. Optional buy some metal corners to do the job if you like overkill and don't thrust your mother. | [17]GitHub,

[18]Direct |

1 |

Extruder_Idler_1_Off.stl |

RP | Extruder | Holds the extruder idler that squeeze the filament up against the hobbed bolt for consistent plastic feeding. Holds a 608 bearing with a short M8 threaded rot or preferably a sjort 8mm smooth rod. You need 1 of this for each Adapto Printer you build. | [19]GitHub,

[20]Direct |

1 |

Large_Gear_T36_1_Off.stl |

RP | Extruder | Turns the hobbed bolt for filament feeding. It have 36 tooths and fits a M8 hobbed bolt nicely and have room for a M8 captive nut allowing it to lock on to the hobbed bolt using an additional nut. You need 1 of this for each Adapto printer you build. | [21]GitHub,

[22]Direct |

1 |

Small_Gear_T13_1_Off.stl |

RP | Exruder | Sits on the extruder motor and turns the large gear. Locks to the motor axle with a M3 captive nut with M3 screw. You need 1 of this for each Adapto printer you build. | [23]GitHub,

[24]Direct |

1 |

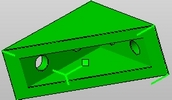

Extruder_X_Carriage_Combo_1_Off.stl |

RP | Exruder | This is both the X-carriage and extruder combined in one plastic part. It holds the weight of the nema17 close to the X-smooth rods to prevent shaking and holds the 3 linear bearings making the x akses slide smoothly. You need 1 of this for each Adapto printer you build. | [25]GitHub,

[26]Direct |

2 |

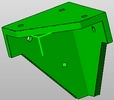

Z_Smooth_Rod_Holder_Lower_2_Off.stl |

RP | Frame | To hold the lower end of the Z smooth rod firmly to the frame. It fits a 8mm smooth rod nicely and ads another good looking part to the design. You need 2 of these for each Adapto printer you build. | [27]GitHub,

[28]Direct |

2 |

Z_Smooth_Rod_Holder_Upper_2_Off.stl |

RP | Frame | To hold the upper end of the Z smooth rod firmly to the frame. It fits a 8mm smooth rod nicely and ads another good looking part to the design. You need 2 of these for each Adapto printer you build. | [29]GitHub,

[30]Direct |

1 |

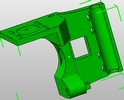

X_End_Idler_1_Off.stl |

RP | Frame | Holds the X smooth rods, Z threaded rods firmly to the frame, the Z linear bearings in place and X idler in position to make the best possible print results. You need 1 of this for each Adapto Printer you build. | [31]GitHub,

[32]Direct |

1 |

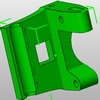

X_End_Motor_1_Off.stl |

RP | Frame | Holds the X smooth rods, Z threaded rods firmly to the frame, the Z linear bearings in place and X motor in position to make the best possible print results. You need 1 of this for each Adapto printer you build. | [33]GitHub,

[34]Direct |

1 |

Endstop_Holders_X_3.stl |

RP | Frame | Holds the end stops firmly to the frame. Some changes may be expected in these soonish but will do for now. you need to print 1 of this STL for each Adapto printer you build. | [35]GitHub,

[36]Direct |

|---|