A list of common problems

Here you find a list of common problems which can occur during the print.

Contents

Object bend up from the heatbead (ABS)

I had this problem under the following environment:

- Printer: reprap prusa i3

- Extrude: mgs

- Nozzle: jhead 0.5mm

- Filament: abs black 3mm

How it looks during fail:

Solution 1

After many try an errors I found the following solution:

My printer said it has 100°C on the heat bed but it were only 80°C. I had to replace the thermistor. After this I the ABS sticks much better. I set the temperature to 105°C, more than that temperature consume more time (about 20 minutes and longer). It is very important to calibrate the heat bed levelling correct and adjust the nozzle heat bed distance.

Layers broken (ABS)

I had this problem under the following environment:

- Printer: reprap prusa i3

- Extrude: mgs

- Nozzle: jhead 0.5mm

- Filament: abs black 3mm

How it looks during fail:

Solution 1

- Possible reason: the heat bed turned off during the print.

- Reduce the layer height

Bad first layer (ABS)

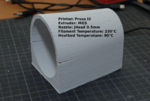

I had this problem under the following environment:

- Printer: reprap prusa i3

- Extrude: mgs

- Nozzle: jhead 0.5mm

- Filament: abs black 3mm

- Temperature: 230°C

How it looks during fail:

Solution

Increase the nozzle heat bed distance

Bad top infill (PLA)

I had this problem under the following environment:

- Printer: reprap prusa i3

- Extrude: mgs

- Nozzle: jhead 0.5mm

- Filament: pla green 3mm

- Temperature: 170°C

How it looks during fail:

Solution

Reduce the perimeter shell to 1