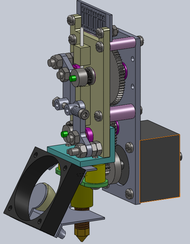

A Nema14 compact dual drive geared extruder

Release status: experimental

| Description | A dual drive geared extruder made with a Nema14 motor.

|

| License | |

| Author | |

| Contributors | |

| Based-on | |

| Categories | |

| CAD Models | |

| External Link |

Introduction

In an earlier post [1] I described a dual drive geared extruder made entirely from scratch and explained why this design could be better than others projects of geared extruders. With ABS and hotend set to 220C and a 0.4 mm nozzle the extruder yielded a flow rate of 25 mm3/s, a good result. But the overall assembly was bulky (but no problem if its used as a Bowden extruder). In this post I describe a more compact version of a Dual Drive Geared Extruder, made with a Nema14 motor. The motor/drives transmission rate was 69:15. The motor used (Applied Motion model 5014-819) was savaged from an old table scanner. Each motor coil have a resistance of 3.8 Ohms and a recommended motor current of 0.5 A. A A4988 driver from the RAMPS1.4 shield can easily run such a motor, but as the motor size and current were small, I wondered if I could obtain a reasonable flow rate. To my surprise, I could obtain a flow rate of almost 25 mm3/s, similar to the former development shown in [2].

Overview

I had in my scrap gears box three modulo 0.5 gears: a smaller one with 15 teeth and two larger, with 69 teeth each. The shaft of a Nema14 stepper motor is attached to the 15 teeth gear. This gear is coupled to a 69 teeth gear connected to the first hobbed drive. The rotation is reversed by another 69 teeth gear that is connected to the second hobbed driver.