A5 Powder bed printer

Release status: Just started

| Description | Building a Powder bed 3D printer.

|

| License | GPL

|

| Author | |

| Contributors | |

| Based-on | |

| Categories | |

| CAD Models | |

| External Link |

The purpose for the A5 Powderbed printer is for experimenters and hobbyist to try different powders, binders and fusion methods without fear of invalidating warranty on a commercial machine, it is also for artists to experiment with the materials and geometries available to digital creation.

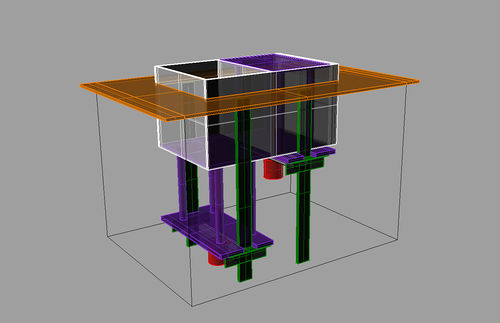

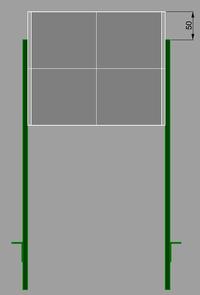

With this in mind, the machine has been designed to be modular, that is to say, the powder bins are the heart of the machine, applying a thin layer of powder being a common task with a smoothing roller or blade.

Powderbed printers have some advantages and disadvantages, the main advantage is that the powder provides the support for the part whilst being built and they can be fast in comparison, colours are a possibility with appropriate software, the disadvantages are the mess they make, good housekeeping is essential, without fusion the parts are not regarded as engineering grade, however the parts can be used for moulding, infiltrated or other secondary operations.

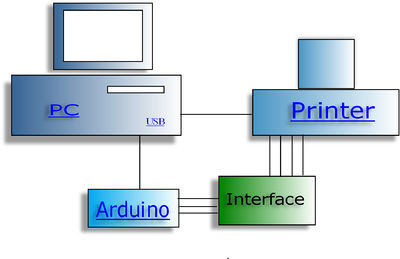

The surface of the powder or, TOP of the machine, can be regarded as a separate entity, the place where binder is applied or fusion occurs, and different equipment can be installed, a plotter driven by EMC2 or Mach3, flatbed printer, plotter or galvanometer guided laser etc to name a few.

A hopper system to dispense powder has a space saving advantage, but may not be as flexible with various powders, needing the powder to be engineered to suit the hopper or the hopper to suit the powder, with this in mind the trusted method of feed bin and part bin have been adopted, although this is no guarantee that the powder will spread in a thin layer out of the bag without some additives or sieving, but should give the most flexibility to use different powders.

The Powderbed printer has been designed to be built with minimum cost by someone with average workshop ability and tools, where the use of machines that may not be available to others in building the prototype, alternatives are suggested.

A5 Powder bed Printer A number of people have built powderbed printers, but a lack of detail makes it hard for many to build their own, I hope to build one and explain each step, so that others can follow, using equipment and materials that are off the shelf wherever possible.

if you want a finished solution, it may be best to wait until it is tried and tested.

Materials The Open 3DP project has been developing DIY powder printers for a few years. They've concluded that USG Hydroperm powder and rice wine "binder" gives good results and are very inexpensive to source.

Printer HP DJ1000 HP DJ2050.. other printer candidates

The HP DJ1000 was the printer of choice for initial development, it looks simple and cheap, and cartridges are refillable, at the time they were difficult to find due to being on special offer, so a HP DJ2050 was purchased instead, this looks like a DJ1000 with a scanner on top, hopefully the scanner will not present extra problems?.

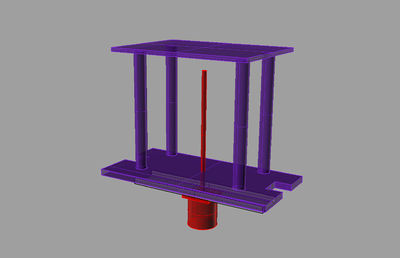

Recoat mechanism

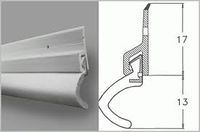

Concealed door slides,(500mm) at £11.50 for two are a cost effective option, they have little or no play and low friction,

3 pairs will be needed.

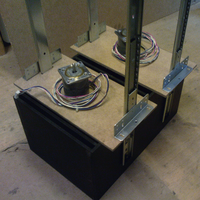

Powder bins and mechanisms

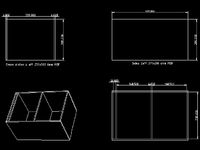

The powder bins are made from 6mm MDF, (£10) to the drawing below, "other sheet materials could be used, melamine coated mdf, tufnol etc", the store cut the parts on a wall saw, this ensures the cuts are square, (no charge for cutting). the apertures are A5 + 10mm all round, to aid part removal, the slot is for overflow The centre lines of the cross plates were marked out, and small holes for panel pins drilled, glue the edges and assemble, making sure all sides are as square as possible to avoid tight spots when the pistons are fitted, then tap in the panel pins, (use small pins to avoid splitting the MDF), double check that the whole thing is square, ( clamp if needed) and leave to set for 24 hours, I coated mine with wood stove paint, to seal it against moisture, which may cause swelling and distortion.

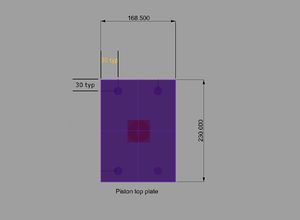

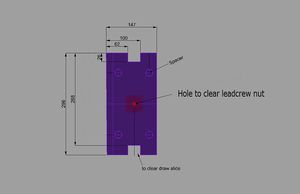

Pistons, The pistons need to move in a smooth manner,without jitter, slop etc, this is to ensure that each layer is directly above the previous layer, we also need to seal between piston and bins to prevent powder getting by, using door seal strip, cut the top piston plate to suit your bins, so that they will pass through without any tight spots but without excessive clearance.

Draw slides are again used for the piston slides, to obtain maximum accuracy at minimum cost and effort.

The top and bottom plate are made from 6mm MDF, they are not critical accuracy, the top plate will have the draught excluder to exclude powder, and the bottom plate is not a close fit to anything, the spacers can be wood broom handle cut to 197mm long, try to get them all the same length for each bin,

Mark on each side plate, the centre line for both bins, select which is to be the top face of the bins and mark 50mm down, and with a small clamp, clamp a slide to the bin so that the small hole is central to the line and the end of the slid is 50mm from the top, with a hand drill or pistol drill, drill out the hole in the slide and through the bin with a 5mm drill, countersink the inside face of the bin until the screw is flush, cut the screw so that it does not protrude through the nut, otherwise it will foul the runner, do the same for the other hole, making sure the slide is square to the bin, and mount the other slides this way.

Brace bars, made from whatever you have available, I used 35mm square wood,cut them so they are a snug fit, not to tight or to loose, with the ends square, this brace bar adds rigidity.

The piston spacers are 20mm wood dowel, cut to 197mm long, the motor plate is made from some of the remaining 6mm MDF, supported by alluminium angle, with the holes for the motors cut with a hole saw.

Motors

Electronics

Software