RBS/Gears

Gear Families

We need Gear Families that all work with each other. This includes popular construction toys. But we're also scaling stuff up to work with Big Iron, like 2"x2" RBS/Beam. And Rack and Pinion.

Release status: unknown

| Description | documenting a generic tool/artpiece

|

| License | |

| Author | |

| Contributors | |

| Based-on | |

| Categories | |

| CAD Models | |

| External Link |

Contents

World-edittable Working Notes!!!

Everything on this page is working notes.

Gear Math and Theory

Gear math and theory is important. We can build it up here, and then give it its own place in the wiki when that makes sense.

Files and Parts

Generic/Daughter_part and CarrotStraightener. (As a gentle style recommendation, it's good to try to keep all your parts and files on the RepRap wiki rather than scattered around so that Mr. Bunny doesn't have to use a scripts and so on to get stuff back onto the wiki.)

Photos and Drawings

Links can be put in captions.

Flicker Example

<flickr>2967868906|right</flickr>

Working Notes

Project Lead(s): Mr. Bunny Wiki-maintainers and helpers:

Forum thread?

Files

Tooling

Description of tooling requirements.

Process

What is making the part like?

Notes

We need cad drawings, background theory, but we also need a "Print this file (with photograph)" and make things with your five year old.

Because we have five year old user builders.

Types

RBS/Gears/Background for theory and names of parts.

Design and Library

- GPL and linux friendly tools for design

- Blender gear script

Common Types

- Meccano/Erector/Vex

- Databases

- Other

Fabrication

Laser Cutter

- Common, works well.

RepRapping

- Precision and Tolerance

CNC mill/router

- Sherline examples

- Taig Mill examples

- Bridgeport examples

Hybrid

Hybrid fabrication; RepRapping and then precise tidying of each layer with a milling/routing head is the most promising.

- Direct: We can make the plastic gear directly

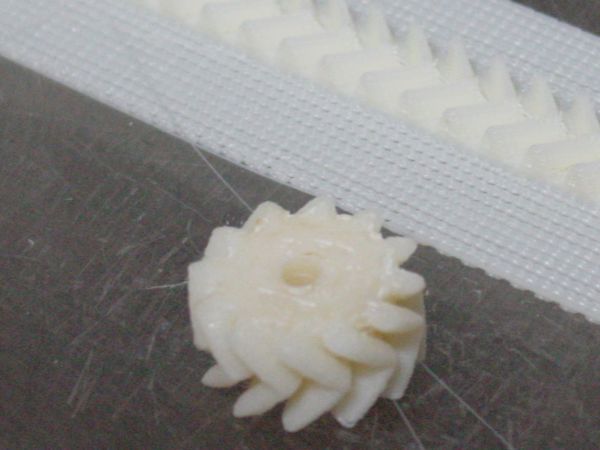

- Mold: We can make the molds for filled epoxy gears.

Hobbing

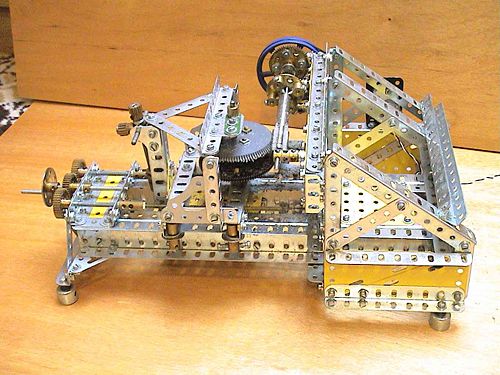

- Timothy Edward's build of a Meccano Gear Making Machine, technically a gear hobber:

via http://edwards.web.users.btopenworld.com/meccano/modelgear.htm

Wire EDM

- Forrest Higgs proposed this once.

Casting/Mouldmaking

- We can make molds for Filled epoxy