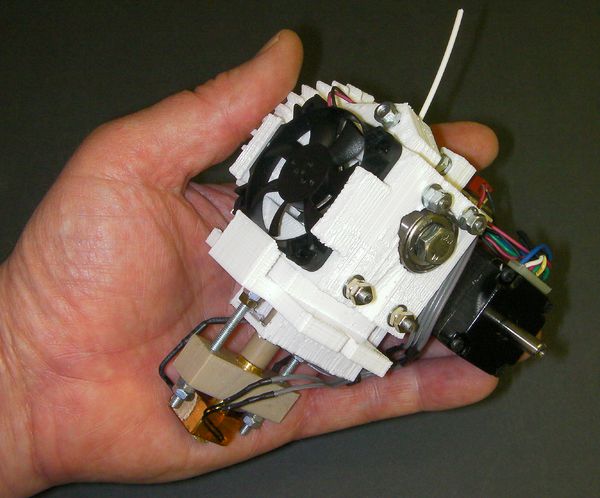

RepRap Universal Mini Extruder

Release status: experimental

| Description | A small extruder for 1.75mm filament.

|

| License | GPL

|

| Author | |

| Contributors | |

| Based-on | [[]]

|

| Categories | |

| CAD Models | |

| External Link |

Introduction

This printable extruder is intended to work on RepRap Mendel, RepRap Huxley, and virtually any other open-source 3D printer you can find.

It features:

- 1.75 mm filament

- Adaptable mounting plate to attach it to virtually any 3D printer

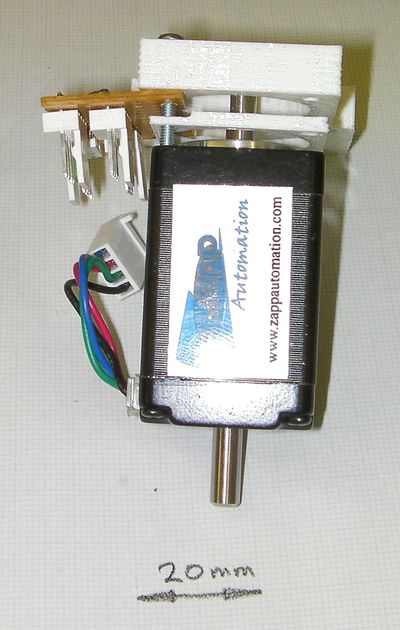

- Very compact high-torque NEMA 11 motor

- Active ducted cooling for high reliability

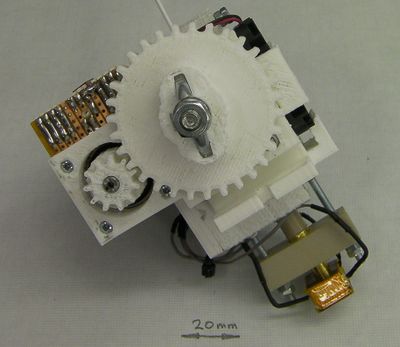

- Wade-style hobbed bolt filament transport

- Wing-nut drive to spread the torque loading on the plastic gears

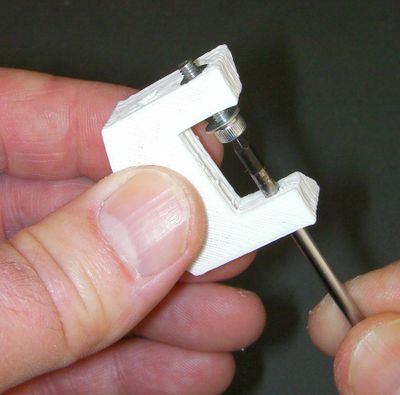

- Push-fit hot-end parts - no thread cutting

- Easily replaced PTFE liner for the hot end

- A single M3-threaded rod cut to lengths makes all the fixings

- Lightweight: 420g (about 60% the weight of this extruder)

- Compact design (110 mm x 90 mm x 80 mm)

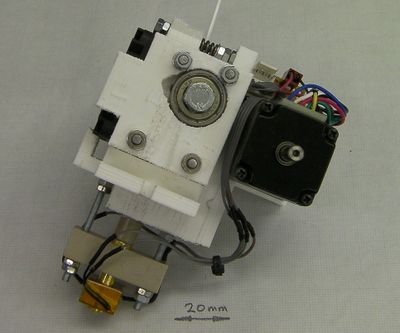

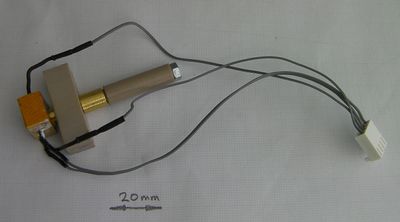

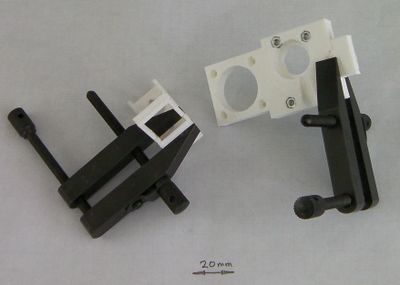

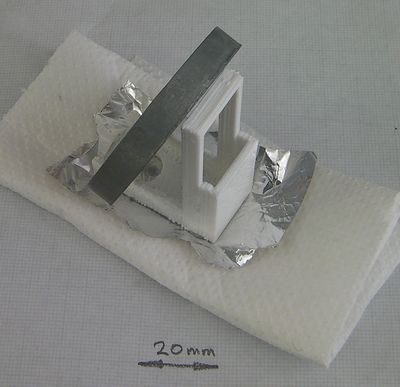

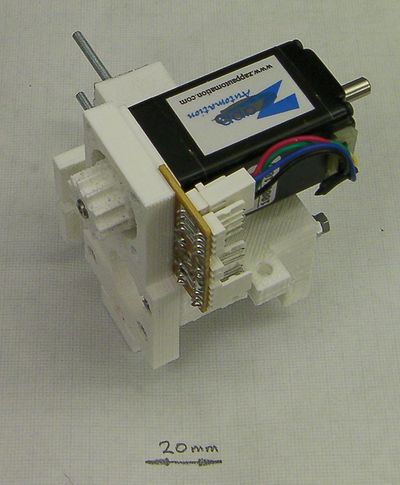

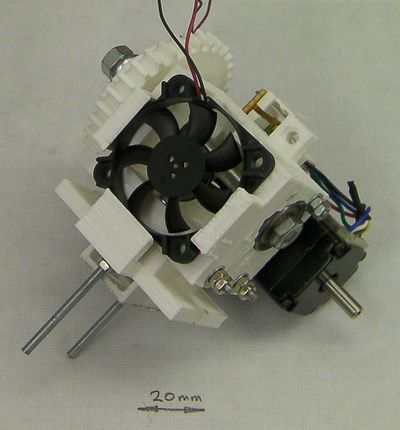

Front view

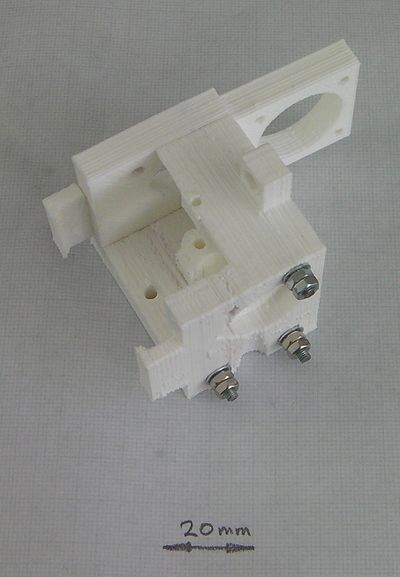

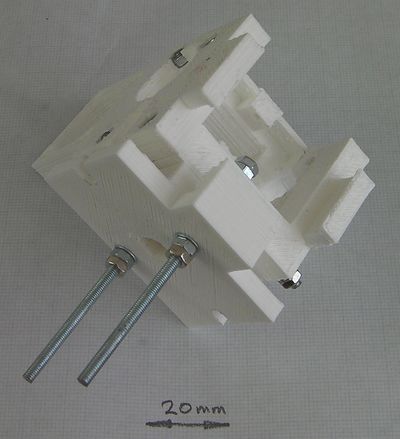

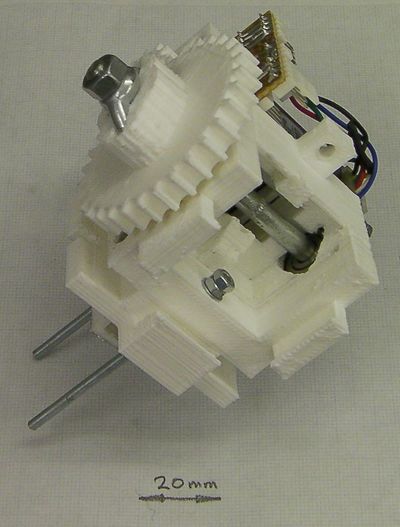

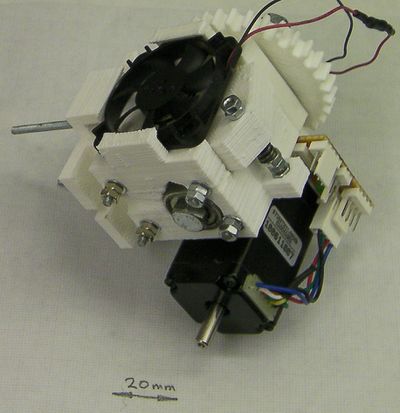

Rear view

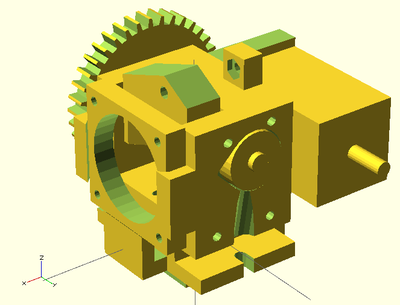

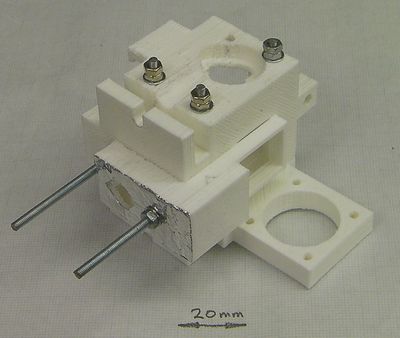

OpenSCAD design.

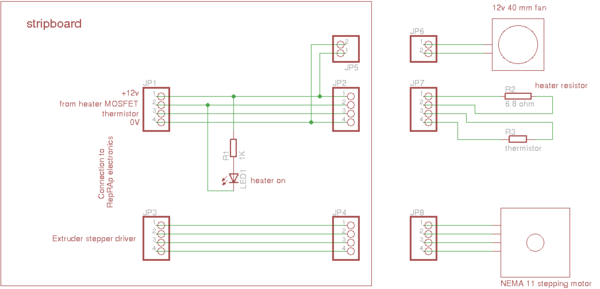

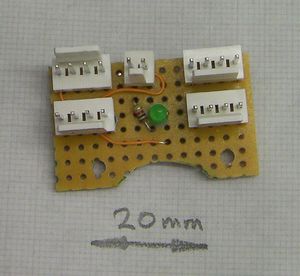

Bill of materials

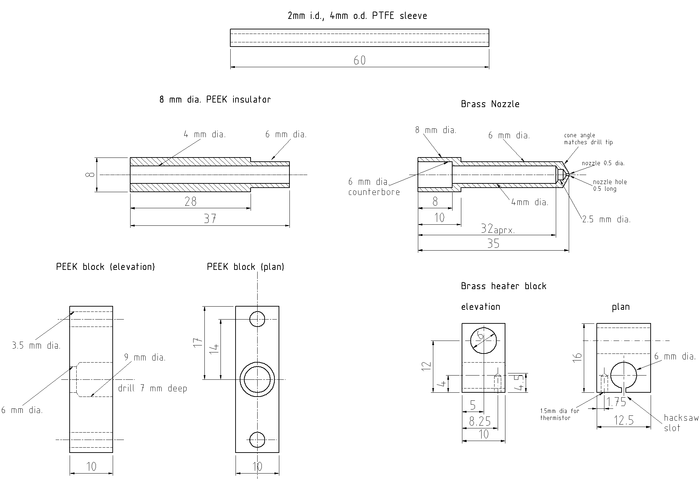

All the design files for the extruder are here in the repository. The OpenSCAD models are in the file universal-1.75mm-filament-extruder.scad, the (very simple) circuit diagram is in Design-drawings/extruder.sch and the drawings of the hot-end components are in Design-drawings/hot-end.dxf.

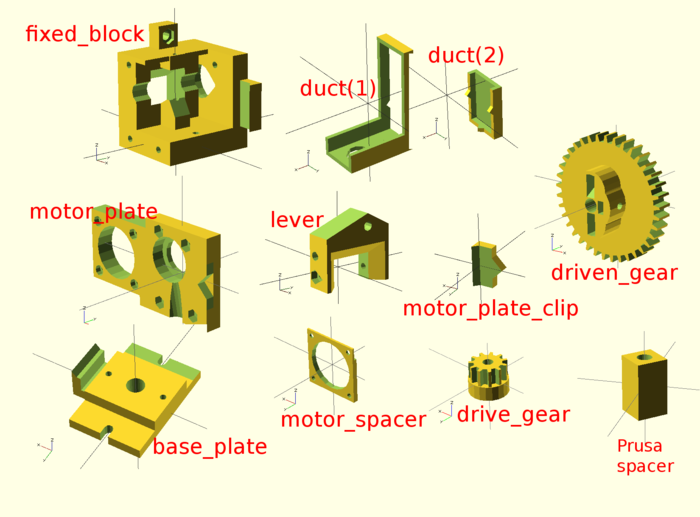

Here is the OpenSCAD rendering of the reprapped components. You will need one each of the above.

The base-plate design is for Mendel. It is easy to adapt for virtually any RepRap and RepRap-like machine, though. The only critical things from the extruder's perspective are the 8.5mm hole for the PEEK insulator, the two 3mm holes 28 mm apart for the tie-rods that retain the hot end, and the support clip for the fan. As long as those are in the right place, just about all the rest of the plate can be anywhere, with fixing holes wherever you like.

- Complete BoM here.

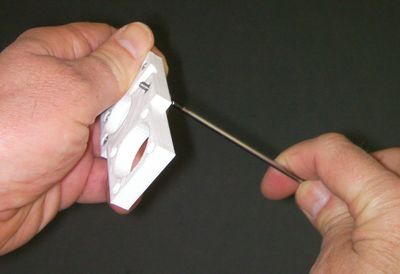

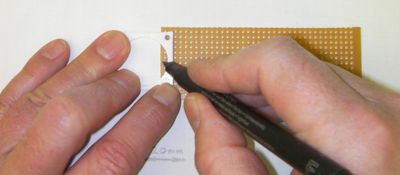

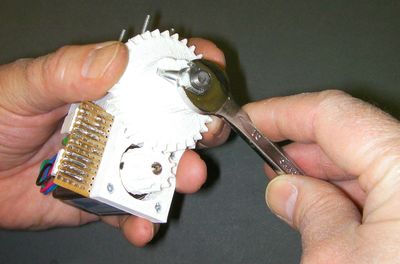

A useful tool

Most of the nuts in this design are in pairs as double lock-nuts. You will need spanners, of course. But most spanners are thicker than the nuts they fit. You may find it useful to get an old bit of sheet steel and cut your own spanner with a hacksaw. I used a straightened-out shelf bracket.

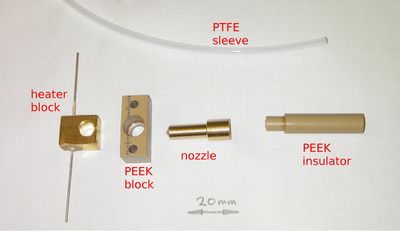

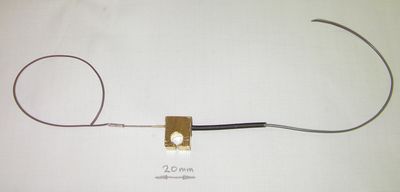

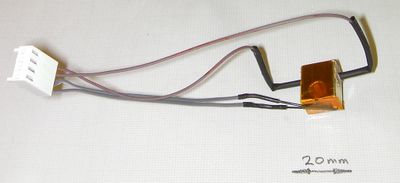

The hot end

Assembly

<videoflash type="vimeo">20596031</videoflash>