User:Powdermetal

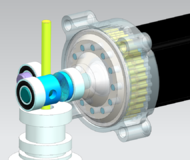

Cycloidal Extruder Drive

Release status: Concept

| Description | Gearbox for direct drive extruders, based on a cycloidal drive

|

| License | GPL

|

| Author | |

| Contributors | |

| Based-on | |

| Categories | |

| CAD Models | |

| External Link |

Contents

Intro

Running a delta printer with a Bowden-style type extruder, many people have been looking into alternatives for a more direct filament feed response (especially when using flexible materials) while still keeping the dynamics of a lightweight effector system. There are a bunch of options out there and each one has it's specific strengths...

Project Target

- Use a small, lightweight and powerful NEMA8/NEMA11-stepper to drive a filament drive gear (like MK8 or others)

- Minimize gearbox package through choosing a cycloidal drive system (gearbox ratio probably between 36:1 and 10:1)

- Setup a potential alternative to the outphased NMB PG35L-048

v0.1

Objective

Quickly check general feasibility using some existing components:

- StepperOnline Nema 8 Bipolar 0.6A 4Ncm(5.7oz.in) mini stepper motor 8HS15-0604S

- MK8 Drive Gear

- E3D v6 HotEnd - 3mm Direct (12v)

Design

- Gearbox ratio: Some simple engineering calculations based on required feed-forces for 3mm filament and comparisons with existing extruder solutions propose for the 4Ncm stepper a gearbox ratio of approx. 20:1. Having an existing CAD model of a small cycloidal gearbox with a ratio of 36:1, this one was simply adopted.

- STEP-files of the assembly with detailed components, simplified geometry for the core parts (for simplifying mods) and some tools/jigs which help you to assemble this thing: Media:CycloExtruder v01.zip

BOM

- Printed parts

- 1 x StepperOnline Nema 8 Bipolar 0.6A 4Ncm(5.7oz.in) mini stepper motor 8HS15-0604S

- 1 x MK8 Drive Gear

- 1 x E3D v6 HotEnd - 3mm Direct (12v)

- 3 x MR105-ZZ (5x10x4mm) Ball Bearings

- 2 x MR128-ZZ (8x12x3.5mm) Ball Bearings

- 1 x 5mm Stainless Steel Precision Shaft (or a 5mm aluminium shaft from your local hardware store - make sure you go shopping with your caliper: 4.97..4.99mm is sufficient if you are on a hurry)

- 12 x DIN6325 2x10 Steel Dowel Pins

- 4 x DIN912 M2x4 Hex Socket Head Cap Screws (for fixing the stepper)

- 2 x Springs

- Various DIN912 M3 Hex Socket Head Cap Screws

Make & Assemble (not easy...)

- Print the parts: PLA, 2 perimeters, 100% fill, go slowly for the gears (15mm/sec or less)

- Tune the excenter's bore to make it go gently over the motor shaft (!) and you can remove it gently again (this is a design weekness...), tune the excenter so you can assemble the bearings smoothly

- Press fit the bearings into the excenter gears, push the over the excenter

- Bolt the ring gear with M2 screws to the stepper

- Move the excenter/excenter gears oover the motor shaft as follows:

- Make the D-shaft look to the left side

- Align the marking dot of the lower gear exactly to the right side

- Align the marking dot of the upper gear exactly to the left side

- Make sure this position is kept, when the excenter gears enter the ring gear

Validate & Test

Results

Todo

v0.2

Objective

xxx