ThermoplastExtruder 2 0

Contents

ThermoplastExtruder Version 2.0

Under construction

Introduction

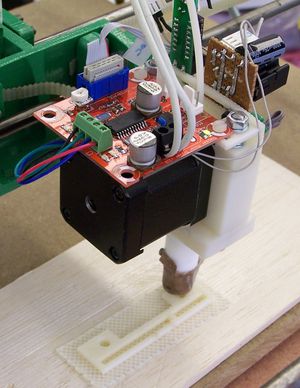

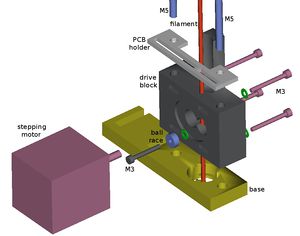

The thermoplast extruder is the central part of the RepRap machine. It takes a 3mm diameter filament of a polymer (usually ABS, polylactic acid, polycaprolactone, or HDPE; the white rod coming into the picture from the top), forces it down a heated barrel, and then extrudes it as a melt out of a fine nozzle. The resulting thin stream is laid down in layers to form the parts that RepRap makes. The extruder should work with most thermoplastics up to a temperature of 250o Celsius.

Improvements and Alternatives

This page describes the standard Version 2.0 RepRap polymer extruder. You may also care to check out the Extruder Improvements And Alternatives section of the RepRap Builders' Wiki for... well, improvements and alternatives.

What order do I do things?

Obviously you'll need all the parts and components first; the bill of materials is linked just there and below.

Start with the controller electronics, which you should have already made and tested if you have followed the order on the Main Construction Page. You'll need this to test and to use the finished extruder.

Next the mechanical parts need to be made.

Then make the heater.

Finally assemble the entire machine and test it.

Safety

%RED%OBVIOUS WARNING: the heated nozzle gets very hot (almost as hot as a soldering iron). It is a bad idea to touch it or the wires leading to it when the machine is working or has just recently been switched off.

LESS OBVIOUS WARNING: The motor drives the filament very slowly. It is well-nigh impossible to get one's fingers in the works, but if one manages to do so, the motor will just keep going and injuries will occur.

WARNING FOR NON-CHEMISTS: The nozzle is partially made from PTFE. PTFE is stable up to 250 oC. Above that it breaks down into various gasses, some of which are quite toxic. The extruder should not be operated above 250 oC.%ENDCOLOR%

Bill of Materials

This page gives a Bill of Materials for the ThermoplastExtruder Version 2.0.

Electronics

Non-rapid-prototyped mechanical parts

Making the reprapped parts

Assembling the extruder

Testing

Filament feeds

History

-- Main.AdrianBowyer - 22 Feb 2009