User:Powdermetal

Revision as of 08:27, 5 May 2016 by Powdermetal (talk | contribs)

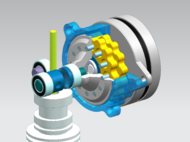

Cycloidal Extruder Drive

Release status: Experimental

| Description | Cycloidal gearbox for a direct drive extruder

|

| License | GPL

|

| Author | |

| Contributors | |

| Based-on | |

| Categories | |

| CAD Models | |

| External Link |

Intro

Running a delta printer with a Bowden-style type extruder, many people have been looking into alternatives for a more direct filament-feed response (especially when using flexible materials) while still keeping the dynamics of a lightweight effector system. There are a bunch of options out there and each one has it's specific strengths...

Project Target

- Use a small, lightweight and powerful NEMA8/NEMA11-stepper to drive a filament drive gear (like MK8 or others)

- Minimize gearbox package through choosing a cycloidal drive system (gearbox ratio probably between 36:1 and 10:1)

- Potentially setup an attractive alternative to the outphased NMB PG35L-048

Build v0.1

Objective

Quickly check general feasibility using some existing components:

- StepperOnline Nema 8 Bipolar 0.6A 4Ncm(5.7oz.in) mini stepper motor 8HS15-0604S

- MK8 Drive Gear

- E3D v6 HotEnd - 3mm Direct (12v)

Design

- Gearbox ratio: Some simple engineering calculations based on required feed-forces for 3mm filament and comparisons with existing extruder solutions propose for the 4Ncm stepper a gearbox ratio of approx. 20:1. Having an existing CAD model of a small cycloidal gearbox with a ratio of 36:1, this one was simply adopted.

- STEP-files of the assembly with detailed components, simplified geometry for the core parts (for simplifying mods) and some tools/jigs which help you to assemble this thing: Media:CycloExtruder v01.zip

BOM

- Printed parts

- 1 x StepperOnline Nema 8 Bipolar 0.6A 4Ncm(5.7oz.in) mini stepper motor 8HS15-0604S

- 1 x MK8 Drive Gear

- 1 x E3D v6 HotEnd - 3mm Direct (12v)

- 3 x MR105-ZZ (5x10x4mm) Ball Bearings

- 2 x MR128-ZZ (8x12x3.5mm) Ball Bearings

- 1 x 5mm Stainless Steel Precision Shaft (or a 5mm aluminium shaft from your local hardware store - make sure you go shopping with your caliper: 4.97..4.99mm is sufficient if you are on a hurry)

- 12 x DIN6325 2x10 Steel Dowel Pins

- 4 x DIN912 M2x4 Hex Socket Head Cap Screws (for fixing the stepper)

- 2 x Springs

- Various DIN912 M3 Hex Socket Head Cap Screws

Make & Assemble (not easy...)

- Print the parts: PLA, 2 perimeters, 100% infill, layer height 0.1mm, go slowly for the gears (15mm/sec or less)

- Tune the excenter's bore to make it go gently (!) over the motor shaft and you can remove it gently again (this is a design weakness...)

- Tune the excenter so you can assemble the bearings smoothly

- Press fit the bearings into the excenter gears, push them over the excenter

- Bolt the ring gear with the M2 screws to the stepper

- Mount the excenter/excenter gears over the motor shaft as follows:

- Make the D-shaft look to the left side

- Align the marking dot of the lower gear exactly to the right side

- Align the marking dot of the upper gear exactly to the left side

- Make sure this position is kept, while the excenter gears enter the ring gear

- Press fit the 5mm shaft into the output carrier (using the shaft-mask tool for perpendicular assembly)

- Press fit the 12 2mm dowel pins into the output carrier (the pin-mask tool and the pin-support-ring tool will help you)

- Assemble all the rest

Test & Validate

- Attached to an Azteeg X5, v1.1

- Motor current: 0.55A, 32 microsteps, 10500 steps/mm

- Retract: 0.5mm, 5mm/sec

- Speed: up to 80mm/sec, 0.4mm nozzle, 0.2mm layer height

- Did some very basic tests (10x10x5 blocks, Dia30 cylinders), in summary 1 hour printing

Results

- It prints

- No lost steps while extruding and retracting

- Some waivy surface appearance (compared to Bowden setup), probably related to poor tolerances

- Motor temperature: reasonable warm

- No specific noise

- No signs of gear wear after tear down - some normal surface flattening, running without grease

- Works basically - v0.1 objectives met

Todo

- Rethink the assembly process - it's a real pain

- Switch to a more effective 14HR05-0504S stepper recommended by Chri and others

- Evaluate tolerance stackup

- Switch to a hypocycloidal profile - build v0.1 uses arcs

- A lot more...

Build v0.2

Objective | Design | BOM | Make & Assemble | Test & Validate | Results

Links

- Wikipedia: Cycloidal drive

- Design of a Planetary-Cyclo-Drive Speed Reducer Cycloid Stage, Geometry, Element Analyses

- Building a Cycloidal Drive with SOLIDWORKS

- http://forums.reprap.org/read.php?1,617389 (This engineer claims 100 grams direct extruder)

- Build v0.1 album