PCB Heatbed

This page is a development stub. Please enhance this page by adding information, cad files, nice big images, and well structured data!

Release status: unknown

| Description | PCB Heatbed

|

| License | unknown

|

| Author | |

| Contributors | |

| Based-on | |

| Categories | addons

|

| CAD Models | |

| External Link |

About

MK2 Heatbed - Minor changes by Tony Lock

I liked Josef's original design but wanted to be able to use through hole components, have the thermistor poke through the middle and for it to look good on the 'back' with the silkscreen that Josef designed on that side as well.

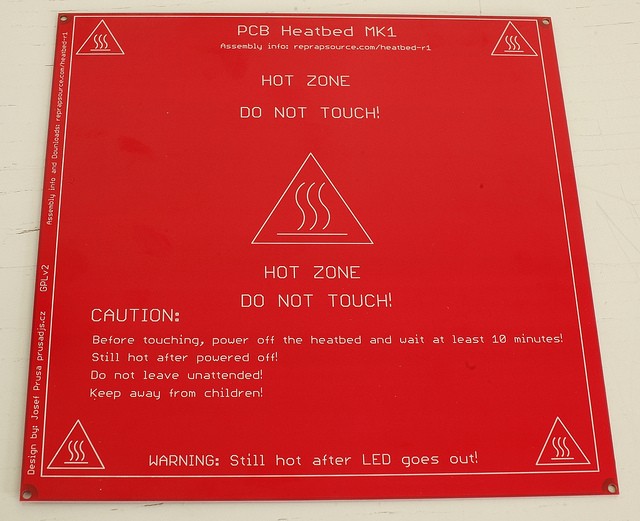

MK1 Heatbed - Developed by Josef Průša

PCB heated bed. I'm working on this idea for nearly six months, inspired by neufeld.newton.ks.us/electronics/?p=864 .

Printing

Cover the bed with kapton tape. Degrease it and print.

ABS temp: 110°C PLA temp: 50-60°C

MAKE SURE YOUR PSU HAS 10 MORE AMPS SPARE!!!

Mounting

MK2

The MK2 board can be mounted either side up and is designed to be mounted as Josef describes: http://josefprusa.cz/pcb-heatbed-final-mounting-and-wiring-solutio The glass protects the tracks from a head crash and is easily swapped out.

The board dimensions are identical to the MK1 design.

Insulation between the board and the thick plate should improve heat-up times and reduce energy consumption. An example is here:

http://reprap.org/wiki/Mendel_heated_bed#Thermal_Insulation

Caution, I have not tried this with the temperatures that the PCB bed can reach!

MK1

Known working solution, I (prusajr) use is Glass sheet (3mm) with glued on cork standoffs and on top of that is glued the heatbed. http://www.flickr.com/photos/prusajr/5410919911/ http://www.flickr.com/photos/prusajr/5410919707/

We are now working on simpler mounting solution! Josef, are you referring to this solution? - http://josefprusa.cz/pcb-heatbed-final-mounting-and-wiring-solutio

When mounted only using the four corners, the inherent warp of the pcb can be a problem, hence it is better to use the cork mounting system above (as the piece of cork in the centre helps to keep the pcb flat). Magnets can be used in replace of the cork, this makes the bed removable. However, I (mooneyj) have only tried this on a darwin type printer (where the build platform only moves in z). During fast printing, the darwin vibrates and it seems the heatbed magnets slide over each other slightly. The acceleration of the y axis on a mendel may cause the magnets to slide also. Perhaps a hybrid of magnet and bolt mounting would work well?.

Note: According to the Eagle file posted on Thingiverse, the M3 holes are spaced 209 mm

Sides

MK2

The PCB still has a side with the traces on and a side without but now the silkscreen is on both the top and bottom, this makes it look good even when 'upside down' under a layer of glass.

The LED, resistor and power wires can be mounted on either side of the board, with either surface mount or through hole components. If you are using through hole be careful when soldering to not have overhang on the other side of the board that could interfere with the glass and introduce a gap between the glass and the PCB.

There is a central hole in the board (similar to this one http://wiki.makerbot.com/cchb1). It is sized so a small thermistor (for example the EPCOS one: http://uk.farnell.com/jsp/search/productdetail.jsp?CMP=i-ddd7-00001003&sku=3878697 ) will fit though it allowing contact directly with the glass. todo: test efficacy of using heat sink compound to better thermally couple the thermistor to the glass

MK1

PCB Bed has two sides, one with the traces (bottom side) and one with silkscreen (top).

Printing on top side is safer, works great.

Printing on bottom is more effective and heats up quicker. (Though the LED, resistor and wire connections are liable to collision with the print head. Also the tracks could be damaged if the print head collides. Make sure your z-bed-springs are not to strong to prevent damage during a collision).

Connection

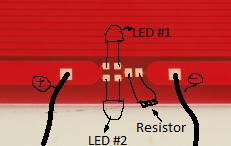

Polarity doesnt affect the pcb, however the LEDs have a polarity, so they must be oriented correctly.

LEDs

There is place for two leds you should put each of them in different direction so atleast one of them is lighten up, no matter what polarity you use.

RAMPS

There are two ways to power the heatbed: 1) You can omit the fuse on the board and use one of the mosfet outputs. 2) Plug one heatbed wire to the GND pin on the mosfet output on RAMPS and connect the 12V+ separately to your powesupply. (Better)

Its now in working state, Printed load of kits on it, working great.

Main Idea is to use resistance of pcb traces as heating element.