GranuleExtruder

Contents

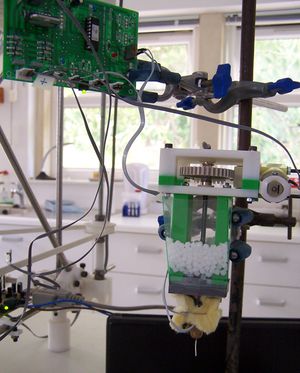

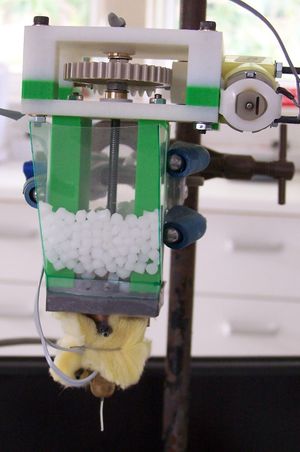

Granule extruder

Introduction

The standard RepRap polymer extruder works very reliably, is simple, and can be made almost all out of RP parts. But it needs a supply of 3mm diameter polymer filament. This is not hard to obtain (many companies can make it from polymer granules), but it does represent an extra cost and an extra process.

The School of Mechanical Engineering, University of Adelaide, in Australia has designed an extruder for Fab@Home that uses polymer granules directly. I was so impressed that I decided to pinch the idea - that's what open-source is all about :-)

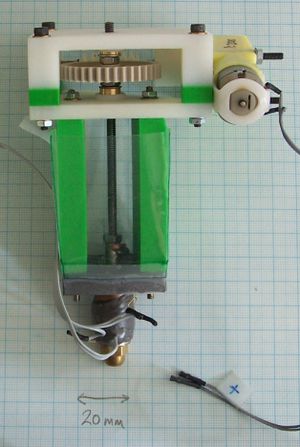

Design and construction

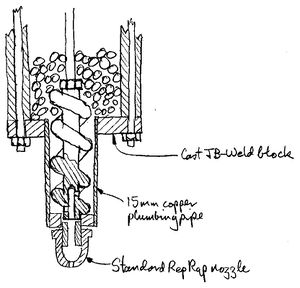

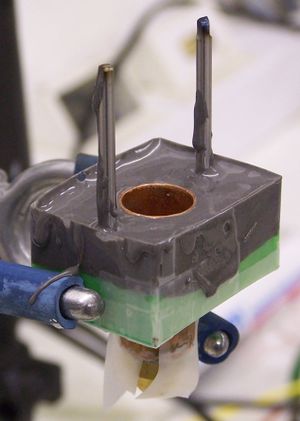

The device consists of a 30 mm length of ordinary copper plumbing pipe with a screw running down the middle. The screw is made from a 6 mm diameter brass rod. I twisted five 1.2mm diameter copper mains wires together to make a fat copper wire, twisted that round the brass to form a helix, and soldered it together. This was much easier than turning the helix in a lathe, and also allowed a variable pitch (finer at the bottom) to be made easily.

At the bottom (I was pleased with this idea...) the screw has a blind hole with side holes between the helical coil. This allows the polymer to flow out down the centre of the screw, down a short length of M6 brass with a hole, into a standard RepRap nozzle made from a brass M6 acorn (or dome) nut.

Testing

Results and conclusions

-- Main.AdrianBowyer - 09 Sep 2007