GUS Simpson assembly

Introduction | Bill of materials | Assembly | Electronics and calibration

Contents

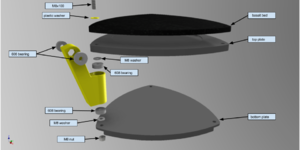

Base

- Start off by building the base. Slide plastic washers on the M8x100 bolts and insert them in the bed.

- Place the heated bed on the top plate, make shure it fits without any bumps, guide the wires through the hole.

- Now carefully slide bed, aligning nuts by hand to fit the holes. You should be able to get it stack with no gaps, if you ended up with gaps - check the heated bed is in place.

- Take 3 M8 washers and slide them on the bolts.

- Place 608 bearings in the Sholders. They should slide right in if you have a good printer, if they dont - carefully try a rubber mullet to get them in. If they still not fitting you should not force the bearings inside. Try heating up the parts in the oven on the lowest temperature and then slide them in.

- Slide shoulders on the bolts.

- Slide 3 more washers on the bolts.

- Slide Bottom plate on the bolts and fix it with nylock nuts. Shoulders must move freely, so dont tighten it up too much.

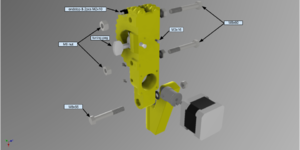

Hub

- Insert 608 and 6702 bearings in each hub part (Hub bottom, hub center, hub top).

- Screw hub screw into the hub bottom.

- Slide hub center, hub washer, hub top on the crew in this order.

- Screw lock nut on the screw, ring on it should face down.

- Screw bowden nut on the top.

- Push the hotend into the hub bottom and fix it with M3 bolts and nuts.

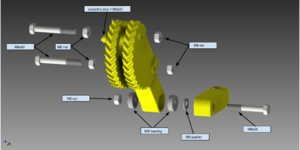

Arms

Before you start assembling arms you should carefully check all the corners of the gears and edges of the holes near the string to be smothe with no sharp pieces of plastic. It is recommended to sand all the inner corners.

- Insert 608 bearings on the arms.

- Start by assembling motor arm:

- Insert 2 M8 nuts into the slots inside the arm.

- Screw M8x60 bolts inside and make shire there is no gap between smoothe part of the bolt and nut.

- Fix these bolts with M8 nylock nuts from the other side. Do not tighten too much, you can break the plastic.

- Screw the spring to the back with M3x16 bolt, it should thread well into the plastic.

- Install the tuning peg, make shure it can be turned.

- Screw NEMA 17 motor on the arm, do not install pulley just yet.

- Assemble the slave arm by inserting M8 nuts screwing two M8x60 bolts just like you did with motor arm.

- Insert two M3 nuts in each pulley.

- Just barely slide the pulleys on the tip of the motor's shafts

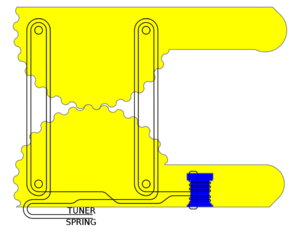

- Tie a string to the spring and string the arms using this illustration

- Cut the string and tie it to the tuner, do not tighten it just yet.

- Push the pulley on the shaft untill holes on the motor arm match the holes on pulley and thread 2 M3 screws into the pulleys in order to fix them solid.

- Tighten the tuner so the hand will stay together.

Finishing

- Insert M8x55 bolts in places on the hub and motor arms.

- Slide a M8 washer on each bolt.

- Join the parts so the motor arms are on top.

- Slide a washer on each bolt again and fix them with M8 nylock nuts.

- Screw essentric stops and limit switches on the arms using M3 and M2 bolts.

- Unscrew the bowden nut from hub, insert a bowden tube through the hole on the nut.

- Screw two M4 nuts on the ends of bowden tube and drill the tume with 2mm drill from the ends.

- Place a nut into the slot on the hub screw and fix it with bowden nut.

- Slide the second nut in the extruder.