FuseBox

FuseBox

Release status: working

| Description | An affordable aluminum-framed CoreXY printer.

|

| License | |

| Author | |

| Contributors | |

| Based-on | |

| Categories | |

| CAD Models | |

| External Link |

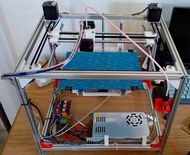

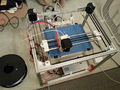

FuseBox is a cheap CoreXY 3D printer that uses an aluminum extrusion frame.

Contents

Goal

To design an affordable, RepRappable 3D printer using CoreXY kinematics that offers high speed and quality.

Features

- Aluminum structure based on Misumi 1515 extrusions and printed brackets

- Uses a stacked variant of CoreXY that eliminates belt crossing

- Total materials cost under $350

- 210x160x200mm build area

- Capable of 0.5mm layer height and 100 mm/s printing

- Mostly RepRappable parts and easily hackable/upgradeable

- Provision for direct and Bowden extruder setups (Bowden currently preferred due to frame rigidity issues)

- Low moving mass—all motors stationary except extruder motor in direct-drive version

- Portable—all hardware and electronics (except for filament spool) are integrated within the frame

- No specialized tools or equipment necessary for assembly

Bill of Materials

Development

Version 1.0

Initial variant. Uses a non-intersecting CoreXY design to eliminate belt crossing issues.

Issues

- Z-axis issues—slight wobble and linear bearing binding

- Slight rigidity issues caused by weak corner joints

- Extruder grip issues leading to inconsistent extrusion

- Untidy wiring

Todo

- Endstop integration (possibly with inductive z-probe)

- Cooling fan addition to improve bridging and top speed for small parts

- Bowden option for lower moving mass (will retain direct extruder for flexible materials)

- Diagonal aluminum braces on sides

- Reduce clearances for additional build area

Version 1.1

Changes'

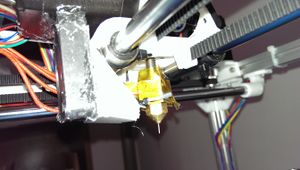

- New compact extruder design with more solid hot end mount and fan duct addition

- Bowden extruder carriage designed; cold end still in development

- 608 bearing idler replaced by a 625 idler

- XY-gantry made more compact, resulting in ~18mm increase in maximum z-axis height

- Z axis changes: bar spacing reduced, additional reinforcement for z-nut crosspiece

Issues

- Slight z-wobble

- Rigidity

Todo

- Additional bracing

- Endstop inregration

Video

<videoflash>I3xibPxbO2s</videoflash>