Creality CR-10 Diamond

Release status: Development

| Description | Creality CR-10 Diamond

|

| License | |

| Author | |

| Contributors | |

| Based-on | |

| Categories | RepRap Color 3D printing

|

| CAD Models | |

| External Link |

Diamond Hotend upgrade guide for the Creality CR-10 family

This is the official build guide intended for those who wish to modify a Creality CR-10 for the Diamond Hotend.

The guide cover the family of Creality CR-10 (CR-10, CR-10S, CR-10 S4, CR-10 S5)

A little warning: this procedure will most likely void warranty on your device, so before proceeding please read this guide thoroughly and be sure you know and understand what you are about to do.

Contents

Part list

These are the parts needed for upgrading with the Diamond Hotend. For printed parts see the Thingiverse link at the bottom of this page.

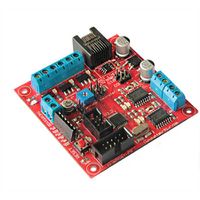

Electronics

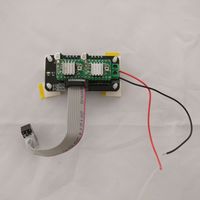

- 1 x Stepper Expander X2

- 2 x Stepstick

- 3 x Stepper Motor

- 2 x Stepper Motor Cable 1200mm

- 1 x Fan 12V

- 1 x Blower 12V

3D printed mount kit

Diamond Hotend

- 1 x Diamond Nozzle 1.7 mm version

- 3 x E3D Lite6 heatsink with bowden fitting

- 1 x Diamond Hotend Insulators

- 1 x Creality Diamond Hotend Upgrade Special Parts

Extruders

- 2 x Creality Extruder

- 2 x Creality Extruder Drive Gear

- 3 x Bowden tube

Assembling

Hardware

- Dismount the original extruder.

- Unscrew the fan mount and cut the wires for the fans. Cut them close to the fans as we need the original fan wires to solder onto the new fans. Please make a note of which wires go to the heatsink fan and which go to the print blower.

- Unscrew the original hotend and release the heater cartridge and thermistor for the hotends heat block. We need the heater cartridge and thermistor to insert into the Diamond Nozzle. Do not cut the wires but if the heater cartridge and thermistor is not fitted with connectors, we recommend to add them for ease of installation, but it's not necessary.

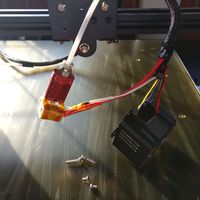

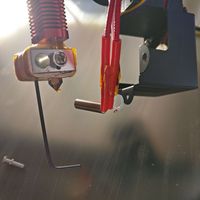

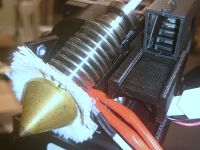

- Mounting the Diamond Hotend.

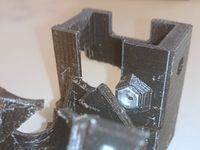

- Insert two M3 nuts into respective slots of the 3D printed mount. One on each side.

- Feed the heater cartridge through the insulators center hole (you can use all 3pcs insulators for extra insulation, however 1pcs can do it), feed the thermistor through the insulators small hole.

- Add heat paste to the tip of the thermistor and the sides of the heater cartridge. Do not use too much heat paste, as it can be hard to insert the heater cartridge fully into the nozzle.

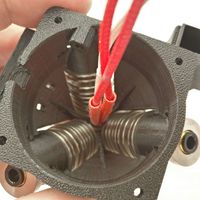

- Insert the heater cartridge fully into the center hole of the nozzle and insert the thermistor all the way into the bottom of the small hole of the nozzle. It's important to have the heater cartridge fully inserted or else the heatsinks can't be mounted correctly

- Before screwing in the heatsinks, we recommend to use some liquid gaskets or PTFE tape on the threads, to prevent leaking.

- Carefully put the thread through the insulator and screw it into the nozzle. Make sure each heat sink will not touch the side of the heater cartridge but they will overlap it and prevent it to fall out. If the heatsink touches the side of the heater cartridge, it's because the heater cartridge is not inserted fully into the hole or it's longer than 20mm. Tighten each heatsink with a plier. Do not overtighten as it can break the neck of the thread

- Fix the wires from the thermistor with the wires from the heater cartridge with a zip tie. Make sure the thermistor is fully inserted into the bottom of the nozzle.

- Feed the wires into the 3D printed mount and carefully slide in the nozzle with heatsinks.

- The heatsinks will click into the mount with a firm push. It takes quite some force to click the heatsinks into place and i have two techniques i use. You could use the palm of your hand to press on the tip of the nozzle but it is painful. Another technique is to use a large nut or similar item for the nozzle tip, to avoid using force directly onto the tip. Never use any force directly on the tip of the nozzle, as it will deform easily

- Inspect each heatsink if its fully inserted into the 3D printed mount.

- Fix each heatsink with a zip tie through the 3D printed mount.

- Fix the heater cartridge and the thermistor wires with a zip tie through the holes in the 3D printed mount.

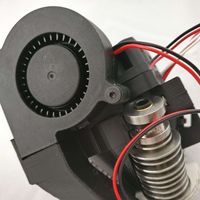

- Use 4pcs M3x20mm countersunk screws to fasten the fan on top of the 3D printed mount. Feed the heater cartridge and thermistor wires out the slot in the back. Make sure the fan is oriented as the picture to ensure the airflow to go into the mount

- Use 1pcs M3x20mm countersunk screw to fasten the blower to the side of the 3D printed mount.

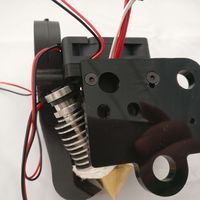

- Use 2pcs M3x20mm countersunk screws to fasten the lasercut hotend mount to the 3D printed mount.

- Use 1pcs M3x10mm screw to fix the complete Diamond Hotend assembly onto the X-carriage.

- Solder the wires for the fan and the blower. Make sure the wires for the original heatsink fan will connect to the new top mounted fan and the wires for the original side mounted blower, will connect to the blower fan. The red will connect to red wire and the black to black. Sometimes there will be a blue and yellow wire for the blower fan and here the yellow will connect to red and the blue wire to the black.

- Dismount the original extruder from the frame and remove the original extruder motor. The motor will be replaced with a more powerful motor.

- Unmount the drive gear from the original extruder and mount it on one of the new and more powerful motors. Mount the 2pcs extra drive gears on the remaining motors.

- Mount the 2pcs extruder motors onto the left side of the laser cut extruder mount. Use 1pcs M3x12mm countersunk screw, 1pcs M3x20mm screw and 2pcs M3x12mm screws to fix them.

- Mount the extruder assembly plate underneath the metal frame and insert the 3. extruder motor from underneath and the extruder from the topside. Use 1pcs M3x16mm countersunk screw, 1pcs M3x25mm screw and 2pcs M3x16mm screws to fix them (please note the screws are longer for this extruder, to compensate for the extra metal frame in between)

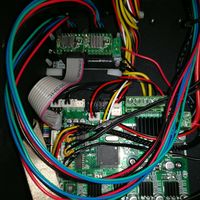

- Now for the electronics. Put the electronic controller box on it's side and unscrew the 4pcs screws (the screws will fix the power supply inside the box).

- Flip the box upside down and unscrew the 5pcs screws holding the bottom plate.

- Release the power supply and move it aside. No need to dismount the wires.

- Your cooling shield should now look something like this.

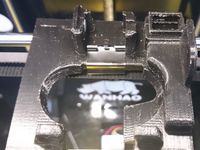

- Grab the x-carriage part and mount the two M3 nuts into the slots as shown on the pictures below. If they are too loose you may glue them into place and if they are too tight to fit you may heat them into place using a soldering iron like described on the Diamond Hotend page step two.

- Align each end of the belt onto the S2M beltclamp and glue these parts together using cyanoacrylate glue. Then align the linear bearings with the x-carriage and press it onto the bearings. After aligning the S2M beltclamp with the x-carriage (see picture) put a bulldog clip around the parts so that it holds the belt in place. Lastly pinch to remove each of the clip handles.

- Mount the top part onto the x-carriage using three M3x10 countersunk bolts. Please observe that the thermal insulations does not get stuck anywhere between the two printed parts.

- Unscrew the Z-endstop switch and reinstall it onto the adapter using two M3 nuts and two M3x8 countersunk bolts. Make sure that the endstop switch is touched by the bed when it is at top position (in case it doesn't you can use the spacers from the original endstop mounting). *Replicator or Creator Pro. No need for endstop spacer, just slide the endstop 2-3mm down.

- Assemble the bowden extruders (following the steps on Diamond Hotend).

- Mount the extruders on the top rear edge of the printer.

- See "Attaching the bowden tubes" as well as Bowden tube hints section on the Diamond Hotend page.

Electronics RAMPS

These instructions will guide you briefly around removing the Mighty Board and install a RAMPS plus a Stepper Expander X1

Beware: Make sure that your RAMPS board and the Arduino MEGA can take the 24 volt from the original power supply of the Duplicator without releasing the magical blue smoke.

- First turn the printer on its side and remove the lid of the electronics compartment.

- Unplug all plugs from the Mighty Board and note where each of them goes

- Unmount the Mighty Board by unscrewing it from the frame of the printer.

- In order to align the USB socket of the RAMPS with the corresponding hole in the frame (6-8 mm) you may need to first glue a couple sheets of eg. acrylic in place. You may be using adhesive pads for this.

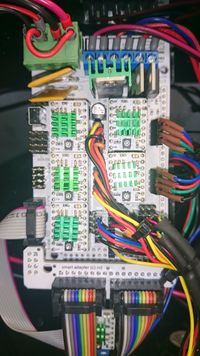

- Mount the RAMPS on top of the acrylic using adhesive PCB spacers.

- Mount the Stepper Expander X1 (or pb ExtrudrBoard) again using the adhesive PCB spacers.

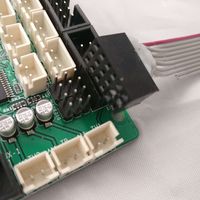

- Connect The Stepper Expander (or pb ExtrudrBoard) to the RAMPS AUX-2 using the 2x5P IDC cable.

- Move the power wires from the Mighty Board plug and connect them to the RAMPS

- Add the power wiring from terminals on the Stepper Expander (or pb ExtrudrBoard).

- Cut the motor plugs and solder on 4-pin female headers, remember to insert each wire through a piece of heat shrink prior to soldering, and carefully crimp it using a lighter flame.

- While observing orientation insert five stepsticks in the vacant positions of the RAMPS board and the remaining stepstick into the Stepper Expander. (The trimpot on a standard A4988 driver should be closest to the power terminals on the Stepper Expander).

- Adjust the extruder stepsticks (or the motor drivers on ExtrudrBoard) to output 1.2 Ampere. See the link section for a separate guide on the subject of current limiting.

- Cut the 120 cm braided sleeve into 40 and 80 cm.

- Feed the extruder motor cables through the 40 cm braided sleeve.

- Also feed the Thermistor Heater and Fan wires through the 80 cm braided sleeve (80 cm).

- Secure the braided sleeves at the rear of the printer

- Tie all wirings in the electronics compartment so that no wires are blocking the airflow from the cooling fans to the stepper drivers.

- Finally attach the optional display to the front.

Electronics RUMBA

These instructions will guide you briefly around removing the original electronics and install the RUMBA electronic

- First turn the printer on its side and remove the lid of the electronics compartment.

- Unplug all plugs from the original electronic board and note where each of them goes.

- Unmount the original electronic board from the frame of the printer.

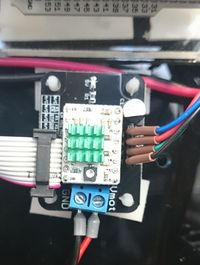

- Mount the StepSticks into the RAMBO and beware of the correct orientation.

- In order to align the USB socket of the RAMBO with the corresponding hole in the frame (6-8 mm) you may need to first glue a couple sheets of eg. acrylic in place. You may be using adhesive pads for this.

- Attach the +24V power wires to the RAMBO in both the POWER IN and HEATBED IN screw terminal and add the Hotend heatsink fan to the +24V.

- Cut the motor plugs from the stepper motor wires and screw each into the screw terminals of X, Y, Z, E0, E1 and E2. Make sure you will have a motor coil (low resistance) in pin 1+2 and pin 3+4.

- Attach the Hotend thermistor to T0

- Attach the Hotend heater to HE0

- Attach the Hotend blower fan to FAN0

- Adjust the StepSticks to output 1.2 Ampere for all Extruder motors. See the link section for a separate guide on the subject of current limiting.

- Cut the 120 cm braided sleeve into 40 and 80 cm.

- Feed the extruder motor cables through the 40 cm braided sleeve.

- Also feed the Thermistor Heater and Fan wires through the 80 cm braided sleeve (80 cm).

- Secure the braided sleeves at the rear of the printer

- Tie all wirings in the electronics compartment so that no wires are blocking the airflow from the cooling fans to the stepper drivers.

- Optional you can add +24V and GND (R,G,B) to the LED strip.

- Finally attach the optional display to the front.

Sources

Part files

- "Diamond mount for Replicator/Duplicator" on Thingiverse - http://www.thingiverse.com/thing:899168

- Z-endstop_holder.stl

- MK9_wide_right.stl

- S2M_beltclamp.stl

- Wanhao Diamond cooler shield ver3.stl

- Wanhao X-carriage ver3.stl

- Flashforge Creator Pro LCD panel front.stl

- Diamond Hotend Insulator - http://www.thingiverse.com/thing:720520/#files

- diamond_thermal_isolation.dxf

Links

- This guide - http://reprap.org/wiki/Duplicator_Diamond

- Diamond Hotend general guide - http://reprap.org/wiki/Diamond_Hotend

- Stepper Expander - http://reprap.org/wiki/Stepper_Expander

- Adding more extruders - http://reprap.org/wiki/Adding_more_extruders

- Current limiting your stepper drivers, see section "current limiting" - http://reprap.me/pololu.html