Thermal

Release status: Stub

| Description | Laser Etching, Drill and 3dprinter

|

| License | Attribution - Non Comercial - ShareAlike

|

| Author | |

| Contributors | |

| Based-on | |

| Categories | |

| CAD Models | |

| External Link |

idea's:

-vaneer sheet's, stanless steel pipe's as rail's, at proto parts MAHONGY tree but part's can be printed from ABS as well

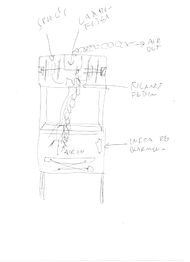

-increase and stabilize object temperature while printing, this done fully closed system whit INFRARED heating, first test whit single 300W ceramic

-keep filament material's clean space

-active circulation of cooling and warm air + filtering inside and out, dust free printing

-collecting hazardouze gas and filtering it before release outside

-laser etching process for PCB prototype production

-drilling small hole's to PCB

-multi head printing

-my perosnal note's: [1]

First proto:

-work area 1000 x 500 x 500, effective work area about 980x480 , device 1000 x 2000 x 500

Motion's

-X linear open linear ball bearing two D=20mm rail's 1000mm

-Y linear open linear ball bearing two D=20mm rail's 500mm

-Z non linear "lab Jack style" elevating table, SFU1204 Ball Screw Ballscrew

-Z2 there will be fast speed Z movment at drill tool

-step motors: I'am testing suitability os Y NEMA17/extruders , X,Z axis NEMA23 2A-4A and

difrent drivers

Electronics:

-four colour touch screen

-at proto mechanical switches, but real version hal

-IR temperature sensors sensing object temperature

-ULTRA SOUND collision prevention

-small line laser's to fast visual calibration of X,Y,Z trough USB CAMERA

Laser for etching:

-ideas development: [2]

-trying perhaps 500mw blue ?

-2W optically guided ideal but expensive

Firmware:

-open question, merlin or teacup or reprappro, i will start whit DUE and reprappro

Lab jack proto:

Building platforme chassis:

3 storage housing:

2:nd waiting chasis

my tidy electronics lab,.. there is allways project open: