Stix

Release status: Experimental

| Description | Motion Component Concept

|

| License | |

| Author | |

| Contributors | |

| Based-on | |

| Categories | Experimental

|

| CAD Models | |

| External Link |

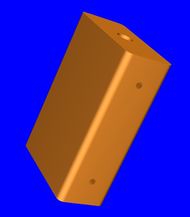

The Stix concept puts two electric motors and two end travel sensors with a leadscrew and a leadnut carrying magnets in a rectangular or square hollow tube. A linear potentiometer element may be included. The connection to the driven part is magnetic through the wall of the tube. The concept aims to make long lasting linear motion elements which resist contamination, stay lubricated, can self-document through printing on the outside (Alumiphoto would resist abrasion), and leverage the invested time and effort to provide a long lasting payback period. I am actively experimenting with this.

One thing I'd like to try is a combined resolver and end travel sensor. Since it's dark inside the tube, two emitter / sensor pairs could be fitted in on the far side of the motor from the leadscrew and short optical filaments led past each motor to diagonally opposing positions near the motor face. A white/clear dual extruded disc over the leadscrew would be the resolver and the leadnut would be white; as the leadnut approached the filaments resolving would degrade, indicating an end travel condition--a soft stop. There are no missed stepper motor steps or need for a linear potentiometer with this refinement and it is a closed-loop control.

The wires can be brought out most inexpensively to an RJ45 connector with nonstandard assignments but the self-documenting feature takes care of any concern about the nonstandard usage. A plug hanging off the end is cheap and the tab can break. It can be fitted with a coupler to protect the tab. The coupler can fit in the tube as an option.

The mating parts would probably be printed or cut from extrusion in angle channel form with four magnets each. It seems the internal lead nut would carry eight magnets for a square tube. A convention of North out seems reasonable for the leadnuts.

The leadnut shouldn't be the same material as the tube or the leadscrew; like-to-like welding would accelerate wear there.