Selective laser sintering

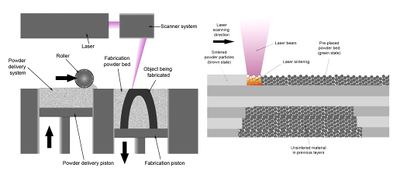

Selective laser sintering (SLS) is an additive manufacturing (AM) technique that uses a laser as the power source to sinter powdered material, aiming the laser automatically at points in space defined by a 3D model, binding the material together to create a solid structure. Direct metal laser sintering (DMLS) is a form of SLS used to create metal objects.

Components

- Build chamber: The chamber around the SLS system used to keep the area heated and to stop laser light escaping

- Heaters: heats the build chamber to just below the temperature needed to fuse the powder

- Powder delivery system: provides powder to the printer

- Recoater: adds layers of powder on top of the model to be fused

- Laser: fuses the printing medium together, the heated build chamber allows the use of a lower powered laser

- X-Y scanning mirror: directs the laser light to the correct place

- Build platform: The platorm which objects attach to as they are built

- Overflow bin: stores excess print powder which is produced as each new layer of powder is added before the laser sinters the layer.