Roboro

Release status: Experimental

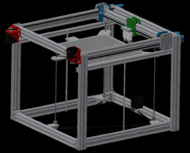

| Description | Roboro is a CoreXY design by tjb1

|

| License | |

| Author | |

| Contributors | |

| Based-on | [[]]

|

| Categories | |

| CAD Models | |

| External Link |

Contents

Introduction

The Roboro is a CoreXY kinematics printer. It uses Openbuilds V-Slot as the main component with custom made brackets that allow interfacing with the Openbuilds V wheels. The main design considerations were the 300x300mm print area, height is only a factor of vertical extrusion, smooth rod and threaded rod length. Many components are symmetrical to lower build complexity and have been designed to utilize the extrusion profile as efficiently as possible. The current design has enough travel to take 4 - E3D hotends completely off every side of the bed to allow future modifications like a purge/wipe area. Only 2 of the hotends are currently shown but the carriage can be mirrored around the X extrusion.

Specifications

- Printed Parts: 20 (Rough Number)

- Non-Printed Parts: Unknown at this time

- Material Cost: Unknown at this time

- Cost: Estimated to be near $700-$800, some parts are custom at this time

- Printing Size: 300mm x 300mm

- Precision: Unknown at this time

- Speed: Unknown at this time

Development

No parts have been released at this time as they are still undergoing major rework as the design progresses.

Future files may be hosted on Thingiverse and Github.

Drive

The X-Y drive uses 6mm GT2 belts with 30t pulleys on the motors, all idlers are currently 608 bearings. The 30t pulleys are required as they place the belt perfectly in the extrusion profile. I am investigating the use of crowned bearing covers to use with 688 bearings. SDP-SI Synchromesh is also being investigated as a possible replacement that would allow easier placement in the extrusion. All idler/drive (top of stepper shaft is supported by MR105 bearing) locations are fully supported to allow adequate tensioning without altering belt direction/travel.

Z-Axis

The Z axis is currently unfinished. Drive mechanisms are still being considered but three drive screws is the current design, a belt driven Z is currently being researched but looks to be a poor candidate due to the weight of the bed which may be plasma cut from steel. The three screws will be linked by a 6mm GT2 belt to one stepper to allow easy leveling (using screws) and maintain synchronization.

The Roboro is still in early development with prototyping to begin 1/15/2014.

Development Pictures

Printed Parts

No parts have been released at this time as they are still undergoing major rework as the design progresses.

Future files may be hosted on Thingiverse and Github.