RepRap project FAQ/de

|

English • العربية • български • català • čeština • Deutsch • Ελληνικά • español • فارسی • français • hrvatski • magyar • italiano • română • 日本語 • 한국어 • lietuvių • Nederlands • norsk • polski • português • русский • Türkçe • українська • 中文(中国大陆) • 中文(台灣) • עברית • azərbaycanca • |

Question: Why is this in English?

Team reprap-dev deutsch is just getting started translating this into German. Ongoing discussion

Question: Where should we start?

By translating this stuff from the General FAQ into German.

Question: What about stickies in the reprap-dev-deutsch foum?

If you've got that many stickies, some of them should be "official documentation", (wiki pages) and some of them need to be ongoing conversations.

Contents

- 1 Wie man in's Wiki schreibt - ganz einfach

- 2 General introduction

- 3 Community

- 4 Overall composition of the RepRap

- 4.1 Tool Heads

- 4.2 Mechanical 3D robot

- 4.3 Electronics

- 4.4 Firmware

- 4.5 Software

- 4.6 Additional tools

- 4.7 Project organization

Wie man in's Wiki schreibt - ganz einfach

Im Wiki zu schreiben ist nicht schwerer als im Forum auch. Wenn man angemeldet ist, gibt's ganz oben auf der Seite und rechts von jeder Überschrift "Edit"-Links. Die einfach klicken und in dem dann erscheinenden Textfeld schreiben. Formatierung ist erst mal zweitrangig, das kann man auch später noch einbringen.

Überschriften stehen in einer eigenen Zeile und werden durch Gleichheitszeichen eingerahmt. Je mehr Gleichheitszeichen, desto kleiner die Überschrift: =Überschrift= ==Unterüberschrift== ===Unterunterüberschrift=== . Links werden in rechteckige Klammern geschrieben: [http://...]. Das ist auch die einfachste Form, Bilder einzubringen.

Texte anderer Leute zu löschen kommt oft schräg rüber, daher eher was zusätzlich schreiben, was die ursprüngliche Meinung ergänzt. Seiten Anderer zu ergänzen ist dagegen ausdrücklich erwünscht (Naja, ausser der Wolfstrap-Seite ;-) ).

Wer mehr lernen will kann einen einfachen Trick anwenden: Eine Seite suchen, die das, was man haben will, schon macht, dort auf "Edit" klicken und einfach abschreiben oder Rauskopieren. Dass man da "Edit" angeklickt hat merkt niemand, so lange man nicht unten "Save Page" klickt. Also einfach Fenster schliessen und auf der ursprünglichen Seite weiter machen.

It can be a bit daunting to get started working on and with the Reprap, this page is an attempt to provide an introduction to the general topics related to the project.

General introduction

Adrian Bowyer has provided a rather good introduction to the overall goal of the reprap project, which can be found on the main page of the project. Reprap is a very interesting project because it contains a vast number of fields of expertise. software, electronics, firmware, mechanics, chemistry and a whole range of other fields of study. The RepRap community has developed several 3D printers including Darwin, Mendel, and Huxley. There are several supported RepRap Options.

Adrian Bowyer hat eine sehr gute Zusammenfassung des Ziels des RepRap Projektes formuliert, welches sich auf der Hauptseite des Projektes befindet (Englischsprachig). RepRap ist ein sehr interessantes Projekt, weil es über viele verschiedene Themengebiete geht. Software, Elektronik, Firmware, Mechanik, Chemie und einige weitere Studienfelder sind bei einem Reprap Projekt zu erwarten.

Die Reprap Gemeinschaft hat mehrere 3D Drucker entwickelt, unter Ihnen die Typen Darwin, Mendel und Huxley. Weiterhin gibt es unterschiedliche Optionen (RepRap Options).

Community

Dieser Abschnitt listet verschiedene Seiten auf bei welchen die Community verschiedene Resourcen bezieht sowie verschiedene Links (Foren, Blogs, druckbare Objekte). Der wichtigste Teil der Community sind die RepRap Nutzergruppen (RUG=RepRap User Groups). In diesen Nutzergruppen finden die RepRap(und RepRap-Ableger)-Nutzer zusammen um Teile zu tauschen und neue RepRaps zu bauen. Vielleicht ist auch eine Nutzergruppe in deiner Nähe.

Objekte

Die Objektbibliothek enthält Gestaltungdaten von Objekten welche gestaltet und veröffentlicht sind. Du solltest die Lizenz von jedem Teil prüfen befor du es ausdruckst. Viele Objekte haben keine Restricktionen bezüglich der Nutzung, das heißt es bestehen keine zusätzliche Bedingungen, Ansprüche, etc. Andere Vorraussetzunegn gelten wenn das Objekt geändert wird und dann veröffentlicht werden. Noch andere begrenzen deren Nutzung auf Nichtkomerzielle Anwendungen.

| gedruckete Objekte | Fotos von einigen gut gelungenen Objekten welche mit RepRap gedruckt wurden |

| The RepRap Object Library: Die RepRap Objektbibliothek | Diese Bibliothek ist Teil der RepRap Projektes und enthält für RepRap-Maschinen druckbare Objekte |

Wiki

Die folgenden Seiten enthalten Beschreibungen von Modifikationen und Änderungen welche mit dem RapRep durchgeführt werden können. Diese enthalten Links zu Seiten welche Bauanleitungen für: völlig unterschiedliche Maschinen, alternative Werkzeugköpfe, diverse Objekte welche die Nutzung des RepRap einfacher machen. Diese Projekte befinden sich in unterschiedlichen Stadien, einige sin zu 100% fertiggestellt während andere sin in der Entwicklung befinden. Diese Seiten sind der Ort um sich Anregungen für die Verbesserung des eigenen RepRaps zu suchen.

Forums/Mailing Lists

Das User-Forum ist ein sehr aktives Forum in welchem Entwicklungstipps getauscht und neue Designvorschläge diskutiert werden.

Blogs

Es gibt einen Hauptblog für das Projekt, welcher hauptsächlich für das präsentieren von neuen Entwicklungen an RepRap genutzt wird. Ausserdem haben die meisten aktiven Authoren zusätzlich einen privaten Blog, in dem sie ihre Aktivitäten dokumentieren. Die Informationen der privaten Blogs werden ständig versucht ins Wiki zu übernehmen. Diese Blogs sind außerdem eine gute Quelle für Informationen über individuelle Entwicklungen an RepRaps.

Einige Blogs beinhalten detailierte Recherche über die verschiedenen Einzelteile des Repraps, und andere beschreiben die Konstruktion von RepRaps. Die Qualität der Informationen, Häufigkeit der Updates, usw., sind wie bei jedem anderem Thema auch, von Blog zu Blog unterschiedlich. Die meisten Blogs beinhalten dennoch sehr gute und solide Informationen, und sind es definitiv wert, untersucht zu werden.

Links (Englisch):

Overall composition of the RepRap

Tool Heads

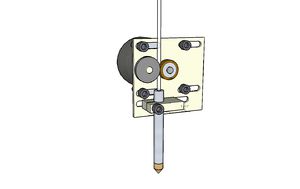

Die verschiedenen Toolheads sind das Herz des RepRap-Projektes. Sie sind das Bauteil, welches RepRap von anderen CNC-Maschinen unterscheidet. Theoretisch kann fast jede Art von Werkzeug mit dem 3D Roboter verbunden werden, dennoch beeinflussen die Struktur und Drehkraft des Motors die Toolhead-Kompabilität. Es gibt im Moment 3 (?) Arten (irgendwelche fräsköpfe? [Dremel?]) von Toolheads, die in Benutzung und Entwicklung sind, mit einer Vielfalt von Varianten. Der bei weitem Beliebteste Toolhead ist der thermoplastische Extruder, oder einfach Extruder/"plastruder".

See: Category:Toolheads

Thermoplastischer Extruder

Wie bei fast allem anderem auch, gibt es eine Vielzahl von verschiedenen Extruder-Designs (Der Mutationsteil von Adrians Vision wurde definitiv Realität). So gut wie alle Extruder arbeiten auf dem Prinzip, dass ein 3 mm Plastikstab durch eine 0,1 bis 0,5 mm weite Öffnung gedrückt wird. Dennoch wird an einem Extruder gearbeitet, welcher stattdessen Plastikgranulat verarbeitet (Granulat ist wesentlich preiswerter).

See: Category:Extruders

Klassifizierung

Die Plastikstangen-Extruder können in zwei verschiedene Typen unterteilt werden, basierend darauf, wo der Motor, welcher das Plastik drückt, plaziert ist.

Klassisch

Beim klassischen Extruder ist der Motor direkt neben der Hitzekammer. Diese Anordnung macht es sehr einfach einen Extruder zu gestalten, welcher mit Steifen und Brüchigen Plastikarten drucken kann. Allerdings erfordert sie, dass die Hitzekammer und die Mechanik für das Einführen des Plastiks als eine Verbundene Struktur gebaut werden, was das Gewicht des Druckkopfes erhöhrt.

Pinch wheel vs. Worm gear vs. direct drive

Die zwei gängigsten Methoden, um das Plastikmaterial in den Heizkörper und aus dem Plastruder zu schieben sind der pinch wheel-Mechanismus, und der worm gear-Mechanismus.

Pinch wheel

Im Pinch Wheel-Design hat die Achse des Motors entweder eingebuchtete rillen, oder ein sehr kleines Zahnrad, welches den Plastikstab fasst. Der größte Vorteil dieses Designs ist die einfachheit, auf kosten den motor langsam laufen lassen zu müssen, und dem Drehmoment benötigt, um den Plastikstab direkt zu manipulieren.

Worm gear

Der Worm Drive überwindet viele der Probleme des Pinch Wheel-Designs. Wegen des Zahnrads kann der Motor auch auf höheren umdrehungen pro minute arbeiten, wodurch weniger Drehmoment benötigt wird. Der Nachteil ist, dass dieser Mechanismus mehr gedruckte Teile benötigt.

Direct drive

This type plastruder is starting go out of commission, due to the improved designs mentioned above. It is listed here more out of historical interests. It suffers from a number of draw backs, like complexity of the design, difficulties with starting and stopping the flow of plastic, causing printed objects to look like porcupines, with small pieces of leftover plastic protruding everywhere (A problem sometimes referred to as "incontinence"), further more it is difficult to mount the vertical drive screw to the axle of the large gear, causing frequent breakdowns.

Bowden Cable

The Bowden cable design separates the mechanism for pushing the plastic rod from the heater element using a bowden cable. This reduces the overall weight which needs to be moved by the 3D robot, at the cost of not being able to print very stiff plastics and a need for slightly more powerful motor and/or gearing.

Common Characteristics

All heaters use electrical resistive components in order to heat the melting chamber, either power resistors for nichrome wire which most people are familiar with in electrical hairdryers/blowers.

The heating of the melting chamber is controlled using closed loop feedback, either PID or bang bang.

Paste Extruder

The paste extruder is largely experimental. There has been discussion of this tool head ultimately being used to print ceramic slip, plaster, and other materials for mold production purposes. Solder paste could potentially be used to print circuit boards.

[balloon & bottle] [syringe direct] [syringe gear] [some other design]

SpoolHead

This tool head is still under development, the goal is to make it possible for the RepRap to layout a section of wire, the current experiments are focused on copper wire, but the principle behind the SpoolHead should make it possible to layout other types of wires as well.

Some of the potentials of this tool head is laying out wires for circuit boards, wiring of spools for motors, both linear and rotratry.

See: SpoolHead

Milling Toolheads

Milling wood, PCBs(electronics) and metals.

See: Category:MillingToolheads

Pen-Holders

Drawing and painting with the carthersian bot.

See: Category:PenHolderToolheads

Others

laser-cutting, pick and place or adapters to mount the toolheads of RepMan, Cupcake or other printers.

See: Category:Toolheads

Mechanical 3D robot

Main article: DriveTrains.

Cartesian Co-ordinate system

At first I was a bit confused about the labeling of the X, Y and Z axis. On the Mendel and Darwin -generation, when standing in front of the machine, you push the bed back and forth in the Y direction, I had expected that direction to be X. That took me a bit by surprise, but upon a little reflection, it makes perfect sense. The coordinate system used by the RepRap is right handed, with the Y axis being the axis going from front to rear of the printer, the X axis going from left to right, and Z axis going vertically up and down.

Polar Co-ordinate system

In contrast: other machine designs rely on the. polar coordinate system Since most 3d printing software generates G&M code which assumes a cartesian coordinate system, an interpreter may be necessary to translate the cartesian positioning information in to polar coordinate instructions. Beaglefury and Galaxyman are two users on the forum currently working on the related math.

parallel manipulator systems

- Delta and Stewart platform:

- Delta Robots and Stewart platform forum http://forums.reprap.org/list.php?178

- The Category:Delta currently lists the Delta, the TRap, the B&TRap, and the Helium Frog Delta Robot. (Is there a more general wiki category for parallel machines?)

- Current version of Delta firmware: http://deltafimware.googlecode.com/svn/trunk/

- Is there a name for the configuration of the "A Hybrid Type Small 5-Axis CNC Milling Machine" by Seung-Kil Son 2002, MIT thesis ?

- Drexler Arm with 6 degrees of freedom

- CNC Hexapod

- Viktor's tripod repstrap demonstrator

- ParalleMIC: the parallel mechanisms information center

RepRap/RepStrap/McWire/HydraRaptor/WolfStrap/and friends

The machines used in the project can generally be divided into three groups, RepRappers, RepStrappers and commercially available forks.

RepRap machines

- Main page: RepRap Options

These are the officially released machine designs, currently either a Darwin or a Mendel, however due to the relatively high mutation rate, there are minor differences between individual machines of the same class.

The Darwin (generation 1)

This is a box like machine, where the Z axis slides up and down using threaded rods in each of the four vertical corners of the box.

Although variations exists, Darwin machines generally all share:

- a box like shape and

- a threaded rod in each of the four corners.

On the Darwin and it´s offsprings like the RepMan the tool head moves along the X and Y axes and the bed moves up and down along the Z axis.

The Mendel (generation 2)

This machine features a more triangular shape when viewed from the side, the bed moves along the Y axis, and the tool head moves along the X axis.

The motion along the Z axis is controlled using two threaded rods, X and Y axis motion is performed using belt mechanisms.

RepStrap machines

Unfortunately it is still a little hard to purchase or get the plastic parts (RPs) needed to build a Mendel or a Darwin. Quite a few end up building a "bootstrap" machine, known as a RepStrap in order to print their first RP parts. All of these machines are frequently built from materials readily available in the local area, leftover scraps of wood and iron rod, with a few select items purchased over the Internet. There is even a kit-build printer called the Makerbot Cupcake ment to be just big enough to print Darwin or Mendel parts.

The project website sponsors a few standard layouts. The McWire seems to be the most popular choice. (Yes the page suggests that you visit another page, because the 1.2 is no longer being actively developed, but the new page isn't really up to speed yet, so this link points to the old page)

Almost all RepStrap machines look very different, on account of the very different materials people have on hand when building a RepStrap. But most share a common trend in that they use threaded rod for motion in all 3 dimensions.

In order to build large object at a reasonable speed the machine needs to be able to move fast in the X and Y dimensions. Unfortunately threaded rod is not ideal for rapid motion; so the RepStrap machine should only be seen as a temporary thing, used only to help create the RPs needed for building a real RepRap machine and then be scraped for other purposes (like becomming a CNC milling machine, where threaded rods perform better against vibration).

Some even suggest that the threaded rod RepStrappers are so slow, that the first things created on a RepStrap should be things which can help to make the RepStrapp move faster, like pulleys for belts, improved extruder heads etc.

Some people end up investing so much time and effort improving their original RepStrap machines, that they prefer their own creation to the Darwin/Mendel they originally set out to create.

RapMan, BfB and other commercial offerings

Since building a RepStrap machine takes time and requires a little mechanical and electrical skill (not much, but a little) some opt to purchase ready made or pre-assembled kits, like the BitsFromBytes RapMan/RapMan Pro or the Makerbot Cupcake machines.

Both commercial offerings appears to be forks off the Darwin (generation 1). Although the machines does not have the latest mechanical features available on the Mendel they are definitely capable of producing the RP parts needed to build a Mendel. The RepMan is even known to be more sturdy and reliable then the Mendel.

Sources of Motion

Belt Driven

This is the current de facto motion technology in use on the Reprap. It is faster than leadscrews which is ideal in a 3d printer.

Screw Driven

Lead screws of various types have been used including:

-all-thread

-ACME

-ballscrews

-wood

Lead screws offer mechanical advantage, however at the expense of speed.

Hydraulics

Hydraulics are powerful, fast, but expensive. Some work is being done on Hydraulics in the RepRap community. Their primary advantage is similar to the Bowden Extruder (Erik's Bowden Extruder, Ed's Bowden Extruder) the ability to isolate the linear actuators(lightweight) from the pump.(heavy)

Pneumatics

Pneumatics suffer from inherent inaccuracies related to the compressible nature of gases. They are fast, powerful, but cannot easily achieve .001 mm precession without taking advantage of a pantograph mechanism of some sort.

Linear Motors

These are very expensive. They could possibly be fabricated from accurately recessed pockets with cemented permanent magnets, however not much is being done on this front ATM.

Electronics

The circuit boards of the RepRap, like most everything else has undergone a rapid series of updates and upgrades. The electronics can be divided several categories

Main board

The main board is responsible for co-ordination between all the sub components of the electronics as well as interacting with the PC driving the RepRap. The primary feature of the main board is a microcontroller. The micro-controller executes a program just like the CPU of a computer does, but instead of using a keyboard and a display as an output mechanism, input/output is done via either sampling the current on one of the pins of the IC or sending out current one of the pins. Which pin is use for input and output is under complete, and the state of output, current/no current or anything in between is under control of the program executed by the microcontroller.

The first version of the main board featured a PIC microcontroller, whereas more recent designs feature the AVR microcontroller. In order to make as wide a range of microcontroller brands available, the firmware of the RepRap has been designed to be compiled by the GNU GCC compiler tool chain. In fact, some people are looking into using the ARM processor.

The shift from PIC to AVR was motivated by the Arduino microcontroller board. The Arduino is an open source hardware project, just like the RepRap, The goal of Arduino is to make it simple to work on custom electronics design using a simple microcontroller. The version 2.3 of the RepRap main board, features a slightly modified version of the Arduino as a part of the components on the circuit board, this slightly modified version was named the Sanguino. The Sanguino features a more powerful AVR microcontroller than the Arduino, both in terms of the number of pins which can be used for I/O and in terms of memory.

Stepper drivers

The Stepper Motor Driver board contains the circuitry to drive a stepper motor used on the RepRap, typically one of the cartesian planes. The current stepper motor driver, v2.3, is based around the Allegro A3982 motor driving chip. There are a number of alternative drivers which have been used by the community, so there is a good deal of flexibility. The official board is recommended due to it's ability to run up to 2 amperes and function without a heatsink. Alternatives have typically been sought because of availability problems.

For a RepRap, you will need at least three stepper motor driver boards, one for each cartesian direction. For stepper driven extruders you will either need another, or the DC motor driver board can be hacked to drive a stepper instead.

This page: Motor FAQ explores the various stepper driver options.

Extruder controller

Opto endstops

wires and connectors

Why do many RepRaps have RJ45 connectors?

People spend more time with wires and connectors than with all the rest of the electronic hardware combined.

The biggest difference in configuration is:([1]; PCB adaptions for Mendel)

- the Makerbot configuration: The extruder controller gets power (and data) through a single very thick cable (with RJ45 connectors) from the motherboard, and the motherboard gets lots of power from a big ATX power supply.

- the "reprap configuration" (is there a better name for this?): The extruder controller gets its power through the thick wires directly connected to the power supply (with clamp terminal connectors), and data through a separate thin wires (with 0.1 inch connectors) from the motherboard; the motherboard gets its power from the USB-TTL cable (which cannot supply enough power to drive the extruder).

- also, some people use big Molex connectors to carry power.

For any one connection, any of these techniques work fine -- RJ45, clamp terminals, Molex connectors, or 0.1 inch connectors -- and many people report success with a hybrid configuration that uses RJ45 to make some connections and the other techniques to make other connections.[2]

RJ45 patch cables and jacks are ubiquitous, versatile, robust, and cheap. If you have another source of high quality premade cables using any connector technology (that we have not already rejected) please bring it to our attention in the "premade cables" forum[3][4][5].

Others

Firmware

- Main page: Firmware FAQ.