RepRapPro Tricolour hot end assembly

|

English • العربية • български • català • čeština • Deutsch • Ελληνικά • español • فارسی • français • hrvatski • magyar • italiano • română • 日本語 • 한국어 • lietuvių • Nederlands • norsk • polski • português • русский • Türkçe • українська • 中文(中国大陆) • 中文(台灣) • עברית • azərbaycanca • |

Introduction | Frame assembly | Y axis assembly | X axis assembly | Z axis assembly | Heated bed assembly | Extruder drive assembly | Hot end assembly | Wiring | Power supply | Commissioning | Printing | Multi‑colour/multi‑materials | Colour Printing - Slic3r | Colour Printing - RepRapPro Slicer | Maintenance | Troubleshooting | Improvements

| A notice about these instructions! |

|

These instructions are open to editing by everyone and anyone. |

Contents

Goal

By the end of this stage you will have finished all the mechanical construction! All that will remain is electrical wiring and commissioning.

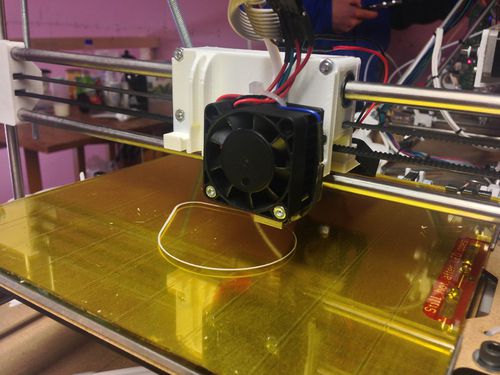

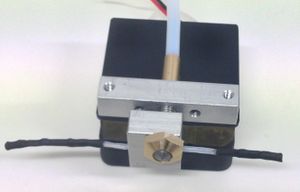

Your hot end will be fitted to your Mendel like this:

Tools

You will need the following tools:

- Allen key

- Small screwdriver

- Pliers

- Adjustable spanner

- Heat sources (small blowtorch plus hairdryer/soldering-iron)

- Bench vice

Parts

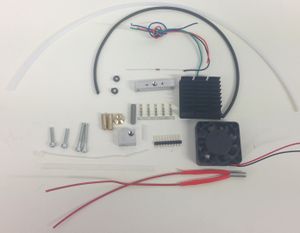

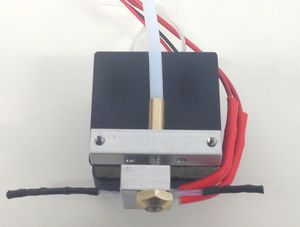

If you have a brass nozzle and separate stainless barrel or a power resistor instead of a heater cartridge like the pictures below, you will need to refer to the archived instructions [here], page 78.

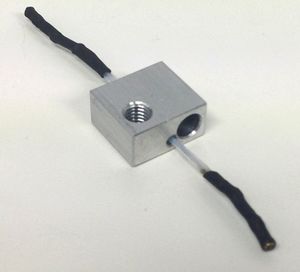

The heater cartridges for the Mendel/Tricolour has red leads as shown in the picture above, the huxley cartridge is similar but comes with white leads.

There are several stages in this construction where you have to trim pieces of PTFE. It is essential to clear any swarf created away and not to let it get into the extruder. PTFE swarf will travel to the nozzle and block it if it is allowed to contaminate the device.

Please note, in newer machines double coil spring washers shown on the left below have replaced the PTFE spacer for extra height adjustment when using multiple heads. These often lock together during transport. Double check your spring washers are separated

Step 1: The hot part of the hot end

The heater block

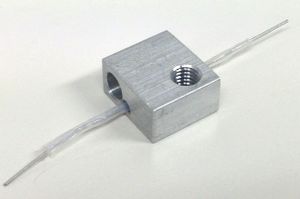

First fit the thermistor. For this step, you will need the axial thermistor, length of PTFE (clear) heatshrink and the heater block.

Cut the PTFE heatshrink such that when slid over the thermistor, approximately 5mm of the leads are bare at each end. With the PTFE heatshrink in position, use a heat source to shrink the PTFE around the thermistor bead and leads. PTFE heatshrink requires temperatures in excess of 300C to shrink. A naked flame will do for this. Keep the flame moving whilst shrinking the PTFE.

Take the sheathed thermistor, and slide one lead into the small hole in the heater block. With the thermistor bead up to the side of the heater block, the PTFE heatshrink should protrude form the other side of the block. Grasp the PTFE heatshrink with some pliers, and pull the thermistor through until the bead is roughly in the centre of the heater block.

Next you will terminate the thermistor leads. Crimp terminals onto the ends of the thermistor leads, then sheath those terminals using black Polyolefin heatshrink.

Set the heater block aside for use in a minute.

The nozzle

It is essential that the nozzle is free from contamination before assembly.

Metal swarf from manufacturing may still be inside it. The best thing to do is to rinse it in a degreaser, use a rolled up piece of tissue to pull out any large parts, rinse in Acetone, and blow air through from the nozzle end. Check you can see daylight all the way through it.

We will need a short length (about 10mm) of 3mm diameter PTFE tube to line the cold end of the one-piece nozzle.

Using a sharp blade, cut one end of the PTFE liner. Try to make the cut as square to the axis of the tube as possible. Push this into the counter-bore at the cold end of the one-piece nozzle. Again using a sharp blade, cut the PTFE liner flush with the cold end of the one-piece nozzle.

Take a 5mm drill and gently twist it against the end of the PTFE that you have just created to dish it slightly. Make sure you clear all swarf away. Now set the one-piece nozzle to one side.

Step 2: The cooling system

Now you will assemble the cooling system.

Take the free end of the extruder drive's PTFE tube. Use a pencil sharpener to make a small cone on about 2mm of the free end of the 4mm tube. Take care not to cut too far - PTFE is very soft.

Screw the brass union all the way onto the free end of the extruder drive's PTFE tube.

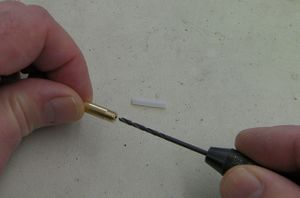

Screwing the tube in will have reduced its internal diameter slightly. Gently twist a 2mm drill by hand in the end of the brass to thin the tube where it is inside the screw thread. If you have a small hand-chuck this is made easier:

Push a length of 1.75mm build filament down the tube from the other end to clear out any PTFE swarf (see the warning above about leaving any behind). Make sure the filament runs freely down the tube and comes out of the far end without impediment.

Some heatsinks come with a sticky backing which you will need to peel off. This can be quite tough - you may need to pull with pliers.

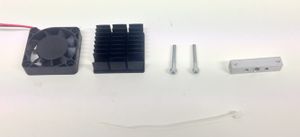

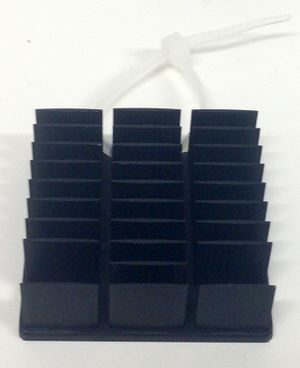

Take the heatsink and the cable tie. You'll notice that one edge of the heatsink has two holes for mounting. Insert the cable tie around one of the fins on the opposite end of the heatsink. This will be used to assist with wiring later.

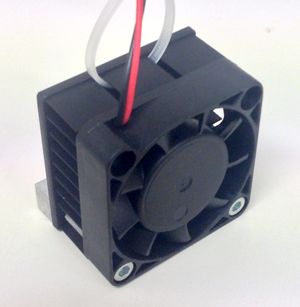

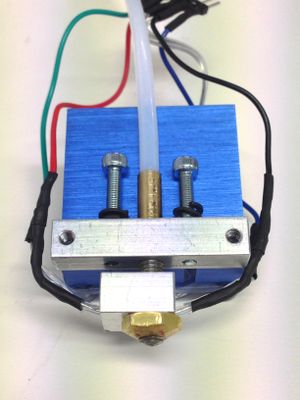

You can put a little heatsink grease on the aluminium cooling block if you like. Attach it to the fan with the two M3x25mm capscrews. Feed the screws in through the fan, through the heatsink and into the cooling block.

Now screw the brass bowden end piece (with the PTFE bowden tube screwed into it), into the Aluminium heatsink block (the long thin one with five holes in it).

Once fully screwed in, screw the free end of the barrel into the M5 hole in the Aluminium heatsink block until it meets the brass piece. Now unscrew the brass piece by 1/4 turn, screw the barrel in to meet it, and finally tighten the brass piece with some pliers. This will result in the barrel and bowden end pieces being locked together inside the heatsink block.

Step 3: Hotend final assembly

The final step is to assemble the hot part of the hotend with the cooling system.

Cut a small piece of Kapton tape and stick it to the bottom of the fan heatsink.

Now screw the heater block onto the one-piece nozzle, and follow it with the brass tapered nut. Tighten the brass tapered nut and heater block together tightly with spanners (more than finger tight!); this will ensure the threads make good contact with the nozzle, and heat transfers well. If you have problems with extrusion despite the temperature being reported correctly, it's worth checking that the brass tapered nut hasn't worked lose.

Next fit the heater cartridge, this just slides into the large hole in the heater block and is held in by friction. Run the wires up around the side of the heatsink and through the cable tie on the top.

The last components to fit are the double coil spring washers. Attach them as shown below using two M3x16mm cap head screws.

You can put an M3 washer above and below each double coil spring washer, if you wish. Using double coil spring washers allows the height of the nozzle to be adjusted individually, so that multiple nozzles can be leveled.

Step 4: Hotend wires

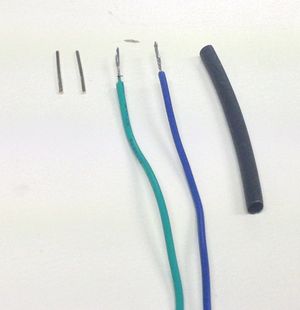

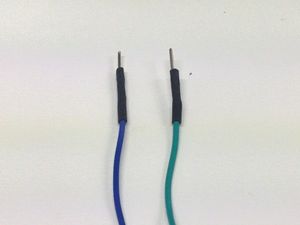

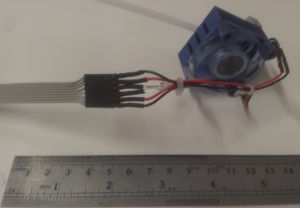

The hotend is designed to be easily removed for maintenance, so a wire connector should be used to connect the hotend to the ribbon cable. two Using 2 spare lengths of motor wire, each approximately 5.5 inches (14 cm) long. Use the green and blue wires so that they don't get easily confused with the red/black wires of the fan.

Solder a single header pin to each, and sheath using the black Polyolefin heatshrink.

These pins just push into the crimps on the thermistors.

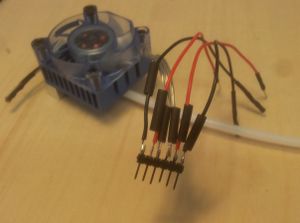

Solder these wires along with the fan and heater cartridge wires to six pins of the male header, in the following order:

- Heater Cartridge

- Thermistor

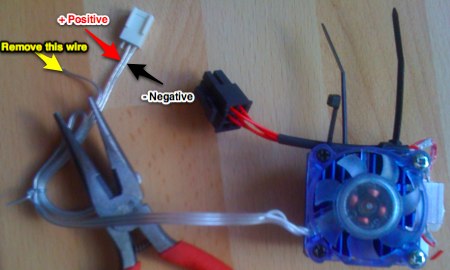

- Fan + volts (Usually red)

- Fan Ground (Usually black)

- Thermistor

- Heater Cartridge

On older fans(blue instead of black) one of the wires from the fan is not used, and the polarity of the wires is not indicated by colour.

Use two adjacent wires from the ribbon cable for each end of the heater cartridge - four in all. This is to increase the current capacity.

The wires across the ribbon cable in order go like this:

- Heater cartridge Wire 1

- Heater cartridge Wire 1

- Thermistor

- Fan + volts

- Fan Ground

- Thermistor

- Heater cartridge Wire 2

- Heater cartridge Wire 2

Heater wires 1 and 2 are arbitrary - the cartridge has no polarity.

This order is designed to minimise the risk of cross wiring the different circuits to the hotend. Since the fan polarity is important, this wire arrangement makes it easy to flip the +ve and ground wires to the fan.

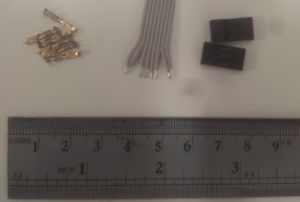

Crimp terminals onto the heater cartridge wire pairs, and onto the thermistor and fan wires.

This step is easiest with the correct tool, such as this one http://www.rapidonline.com/Tools-Equipment/Ratchet-Action-Crimp-Tool-Ht225d-85-0262 If you do not have such a tool, this advice is worth following http://www.youtube.com/watch?v=KEm2PuHBt4Y

Push the terminals into the female housings and fit these to the male header strip.

Connecting up

Bend the wires up the side of the heat sink. Do not pull them tight - they need a little slack to accommodate movement and expansion. Attach them at the top of the heatsink with two cable ties chained together, one of them running through the top slot in the heatsink.

Trim the excess off the cable ties.

Use a meter to check that the resistance between the wires and the aluminium block is infinite and that nothing is shorting.

Also check the resistance of the heater cartridge and the thermistor by measuring from the far ends of the wires. The Mendel heater should be just under 3 ohms or the Huxley just under 7 ohms. The thermistor should be about 100K at room temperature.

Step 5: Installation

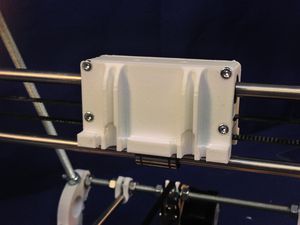

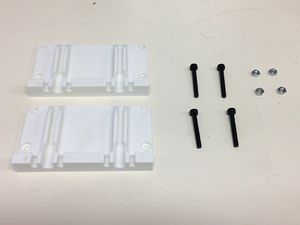

If you haven't already done so for another hot end, you now need to fit the nozzle mounting brackets:

| |

| Hardware | Quantity |

| M3x25mm Cap Screw | 4 |

| M3 Nuts | 4 |

| Printed Nozzle Mount Front | 1 |

| Printed Nozzle Mount Rear | 1 |

You'll notice the front and rear nozzle mounts are slightly different. One has circular holes for housing the head of the cap screw, the other has a hexagonal hole for the M3 nuts.

Insert the cap screws through the holes in the front nozzle mount, through the holes in the x carriage and secure using an M3 nut in the rear nozzle mount.

Then use the M3x25mm cap screws in the aluminium cooling block to attach the extruder hot end to the X carriage of your Mendel. The PTFE tube clips into the printed vertical channel in the X carriage. The springs should fir underneath the lip of the x carriage. Therefore the order is cap screws, x carriage, springs, heat sink block.

Put the free end of the PTFE tube back in the extruder drive and re-secure it with the tongue that you undid at the end of the previous page.

The tube runs outside the machine. It does not run between the threaded rods.

Twist the ribbon cable loosely round the PTFE tube to the top, as shown in the picture at the top of this page. Wrap it 10 turns. Do not pull it tight.

Attach the glass plate to the bed with the four foldback clips.

Screw the Z adjust screw so that about 4mm of it projects below the X motor mount.

Slacken the h bracket that holds the Z endstop switch. Position the Z endstop switch so that when the adjust screw hits it the extruder nozzle is about 1mm above the glass. Tighten the h bracket.

Multi-colour/Multi-material Mendel

If you are building the multi-colour/multi-material version of RepRapPro Mendel then you will need three hot ends in all. Build another two as described above and fit them to the remaining two slots on the X carriage. Twist their wires up the PTFE tube as you did for the first extruder, but wind them at the top and secure them with a little tape for use later.

Adjust the cap screws on the nozzle mounts that raise each hot end by deforming the spring washers so that the first live extruder is lowest and the other two are about 1mm higher