Prusa i3/pt

|

English • العربية • български • català • čeština • Deutsch • Ελληνικά • español • فارسی • français • hrvatski • magyar • italiano • română • 日本語 • 한국어 • lietuvių • Nederlands • norsk • polski • português • русский • Türkçe • українська • 中文(中国大陆) • 中文(台灣) • עברית • azərbaycanca • |

| |

Atenção página em processo de tradução |

Release status: working

| Description | Prusa i3 is a design by Josef Prusa.

|

| License | |

| Author | |

| Contributors | |

| Based-on | |

| Categories | |

| CAD Models | |

| External Link |

A Prusa i3 (iteração 3) precede a terceira versão (i3) MK2 que pode ser encontrada aqui: Prusa i3 MK2. A i3 incorpora a experiência adquirida com os dois projetos anteriores da Prusa, bem como outros projetos modernos e populares RepRap. Veja também Prusa Mendel (iteration 2).

| |

Derivações O modelo Prusa i3 possui um design muito popular, devido a sua popularidade muitas pessoas criaram variações. Catalogamos as variações mais conhecidas em Category: Prusa i3 Derivate. Verifique também A pagina de variações da Prusa i3, assim como a Pagina de desenvolvimento da Prusa i3 |

Contents

Especificações

| Itens | Quadro de uma placa | Quadro Caixa |

| Partes Plasticas (sem extrusor) | 26 | 29 |

| Partes não impressas aprox. | 337 | 293 |

| Custo em dollar | $300-1000? | $300-$800? |

| Placa controladora | Quase todas compatíveis com RepRap | Quase todas compatíveis com RepRap |

| Área Impressa | 200 x 200 x 200 | 200 x 200 x 270 |

| Motores de Passo | 5 x NEMA 17 | 5 x NEMA 17 |

| Material do quadro | Alunínio ou madeira 6mm | 12mm Wood |

| Manufactura do quadro | Corte a lazer, CNC, Corte com jato D'agua | Ferramentas basicas de trabalho com madeira |

| Pro | Facil montagem | XZ rígidas para conexão Y |

| Con | Ferramentas especializadas | Aparencia não tão profissional? |

Principais Melhorias

Abaixo uma lista das melhorias mais relevantes sobre o modelo Prusa Mendel Iteration 2

- Reforçada a rigidez do chassi precinindo assim qualquer folga no eixo x

- Fácil montagem

- Arquivos parametricos para multiplos tamanhos de rolamentos e/ou encaixes

Desenvolvimento

O desenvolvimento da Prusa Mendel está no github: https://github.com/josefprusa/Prusa3.

Historia

Prusa i2: Novembro 2011 [1].

Prusa i3: Primeiro commit no repositorio GitHub em Maio de 2012 [2]

Commit de 3 de Setembro de 2012 por Josef Prusa nomeado: Remontagem final completa [3].

Muitos commits nos seguintes meses , evidenciando o processo de desenvolvimento contínuo.

O número de commits caiu rapidamente após Agosto de 2013

No entanto, isso não é o fim do desenvolvimento da Prusa i3. Veja a pagina de desenvolvimento da Prusa i3.

Em Janeiro de 2014 Prusa moveu o desenvolvimento original para o repositório vanilla emGithub.

Em Maio de 2015 um kit oficial é lançado crado por Prusa.

Variantes

O fato de a Prusa i3 ser lançada sob a licença GPL e inúmeros outros fatores (seu baixo custo, mínimo BOM, procedimentos de montagem e calibração simples, mais do que a devida documentação, etc) têm incentivado o desenvolvimento de um número crescente de variantes da Prusa i3 em todo o mundo, com diferentes partes, materiais diferentes e diferentes processos de montagem, mas que no conjunto seguem à aparência geral, a montagem dos componentes, as dimensões e a funcionalidade da Prusa i3 original.

See the page Prusa_i3_Variants for an attempt to list the Prusa i3 Open Source variants along with their differences / improvements and "genetic lineage". Also check out the Category: Prusa i3 Derivate page which lists using the wiki tagging feature.

Printed Parts

The STL files to make the printer can be found at Clone_wars:_Prusa_iteración_3. and here zipped up: File:Clonewars.zip Please note that the zipped files are not compatible with holes for the Z axis brackets in the Prusa3ALU-*.dxf drawings, at least the ones in the old/ folder in github. Also, the models for Y-axis brackets are for M8 rods. Compiling your own and investigating the Prusa github packages is highly recommended!

To compile it yourself use the files from Github [[4]] (box style files) [[5]] (Single sheet style) Copy configuration.scad.dist to configuration.scad and fill custom settings section there

RP every .scad in this directory (except complete-printer) once.

Aim for 0.3mm layers and 2.2 extrusion width (width over thickness),

for 0.66mm stroke width. Printer is tested at this setting.

Using doc/complete-printer.scad as a visual clue and doc/manual.txt as a guide, build the printer.

Frame type

Most major Prusa i3 Frame Styles fall into two categories: the Single Sheet Frame, and the Box Style Frame. The Single Sheet Frame is designed to be manufactured through the use of a Laser cutter, WaterJet, or CNC Mill / Router Table. There are two current development tracks within the Single Sheet Frame, an Aluminium frame style, and a gusseted Wood frame style. Both are designed to support 6mm or thicker framing material. Both the EiNSTeiN variant and the i3 Rework designs use single sheet aluminum frames, as do most kits. The Box Style Frame, on the other hand, is designed to be easily manufactured at home with basic woodworking tools. The Y-axis for both frame styles is similar to that of the older Prusa Mendel Iteration 2.

Single Sheet Frame

This is a frame created from flat metal sheet, typically Aluminium, but can also be made from other material with a thickness usually between 3mm (0.125 inch) and 6mm (0.25 inch).

Pro:

- Looks professional (subjective)

Con:

- Requires specialized tools (e.g. abrasive water jet cutter, laser cutter, CNC router) or contracting out of cutting.

- Less rigid connection between XZ-frame and Y-frame part, however this can be somewhat rectified by the TwelvePro variant, which provides additional frame support.

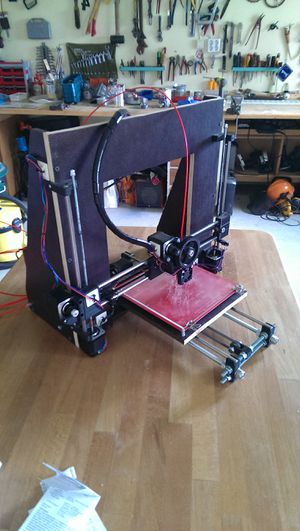

Wood Sheet frame

This is a version of the sheet frame that is designed to be laser cut out of wood or plastic (eg. acrylic) if you don't have access to a waterjet cutter. The only difference is that this version has support gussets on the back side of the vertical frame (the side that doesn't have the z threaded rods).

Construction is the same.

Laser cutting files can be found at github.com/sgraber/Prusa3_LC.

Pro:

- Looks professional (subjective)

Con:

- Requires specialized tools (e.g.laser cutter)

- Less rigid connection between XZ-frame and Y-frame part (Connects in the same way as the alu sheet frame)

Box Style Frame

This frame is created from 8 small sheets of wood.

Pro:

- Can be created with standard DIY tools

- More rigid connection between XZ-frame and Y-frame part

Con:

- Looks less professional (subjective)

Alternate Box frame

This is a version of the boxed frame that uses only 5 parts instead of 8. It requires a little more work when cutting out the parts but less work to assemble.

Blueprints for the box can be found Here[6]

Electronics

Stepper Motors

The Prusa i3 uses, including the extruder, 5 NEMA17 stepper motors. Two of these motors, the Z axis motors, are connected to the same stepper driver of the electronics. If using Wade's Extruder, its stepper motor needs a minimum holding torque of 40Ncm (0.4Nm). More information can be found on the Stepper Motor page.

Controller Electronics

About any RepRap controller works for the Prusa i3. Required features: 4 stepper drivers, 1 thermistor input and 1 heater output for the extruder and optionally another thermistor/heater pair for the heated bed. Choosing the best one for your printer is mostly a matter of taste. For comparisons, see List of electronics, Comparison of Electronics and Alternative Electronics.

Extruder

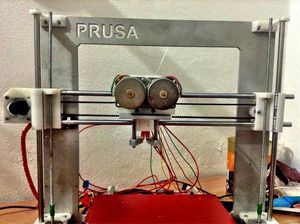

On November 12th, 2012 Josef Prusa (@josefprusa) tweeted a picture of his metal frame i3 with a custom dual extruder mounted.

Previous posts on Prusa's twitter feed reveal that Sound (Slic3r's Developer) inspired Prusa to attach a dual extruder.

In may 2015 was published the &makers single direct drive extruder named &struder, was designed to use on Wood multitool and now is adapted to use on prusa i3.

Heated Bed

The Prusa i3 includes a Heated Bed which allows for the use of materials such as ABS and nylon which can experience significant warping if printing on a cold platform.

- MK3 heating bed, aluminum plate thickness of 3 mm, uniform heating, fast, back has good heat preservation, high temperature can be heated to 120 degrees

Filament Holder

For Sheet Style,

- http://www.thingiverse.com/thing:60720

- http://www.thingiverse.com/thing:68329

- http://www.thingiverse.com/thing:153792

For Box Style,

- http://www.thingiverse.com/thing:104557,but I recommend using threaded rod and bearings with this thing, like this

- http://www.thingiverse.com/thing:111157

Videos

- Montando la Prusa Mendel i3 (Spanish) http://www.youtube.com/watch?v=-31Zn7wY7jk

- Aluminium Body i3 (Spanish) Video montaje completo por capítulos (OverCraft3D)