Pick-n-Place Feeders

See also: Pick and Place ToolHead

Contents

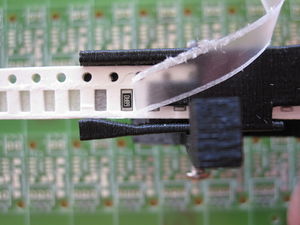

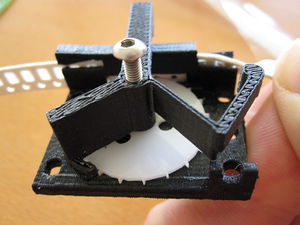

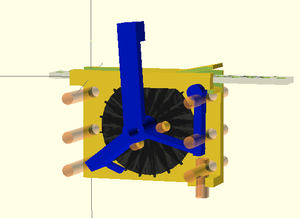

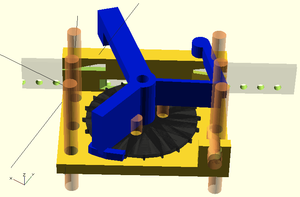

Reel/tape feeder

Erik designed an SMT tape feeder (files available on Thingiverse). Feeders are available commercially Pneumatic Feeder or Electric Feeder. Pneumatic Feeder CL8*2, CL8*4 Made in China is around 80-100 US Dollars which is widely applied in DIY SMT or Desktop Pick and Place Machine in China, electric feeder tends to cost hundreds of dollars each, while the majority of the parts can be printed for less than 20 cents. It is a parametric design that can be easily adjusted for various sizes of SMD tape. The gear will also be adjusted depending on the pitch of the tape and components.

This video shows an explanation of how it works:

Servo Control

The head can be used to move the lever to dispense a new part but can also be done with a micro servo. The micro servos can be controlled individually via the motherboard using serial commands such as 1, 2, or 3. The code is modular and easily expandable up to 12 servos using a Atmel328 running modified firmware with the arduino bootloader. Using an Atmel1280 or Atmel2580 there can be 48 servos. The servos would require a separate 5v supply. Here is some code for testing 3 servos. More code, schematics, and pcbs are to soon follow.

3 Servo Code: http://smt-pick-n-place-system.googlecode.com/files/Pick_and_Place_Componet_Dipenser_Firmware_pde.pde

Tube/stick feeders

Easier to mechanically advance them all, as you can vibrate a whole platform and they will slide forward. Because of variations, a (visual) bottom camera is useful to calibrate for correct part placement. Any epicentric weight on a motor will probably work? Perhaps the part should smash onto it. Another alternative is to have a piezzo induced vibrator.

Manual tape feeders

We're interested mostly in automated fabrication, but these are useful manual systems: on ebay.

Tray feeder

Needs a good camera calibration for adjusting for offset errors (like the stick feeder). Needs to software to remember the empty/filled status of various positions (or allow it to scan for parts!). Feedback on the vacuum pressure at the nozzle tip should also be a way to detect if a part was grabbed.