Mendel Y-axis

Mechanical: Overview | Mendel solid model files | Procurement | Preparation of materials | Assembly notes | Extruder | X-axis | Z-axis | Y-axis | Circuit boards | Frame | Squaring the axes

You may find the Mendel assembly data sheet useful during assembly.

This video shows the working principals of the Mendel Y axis, it may be useful for you understand how it performs:

Contents

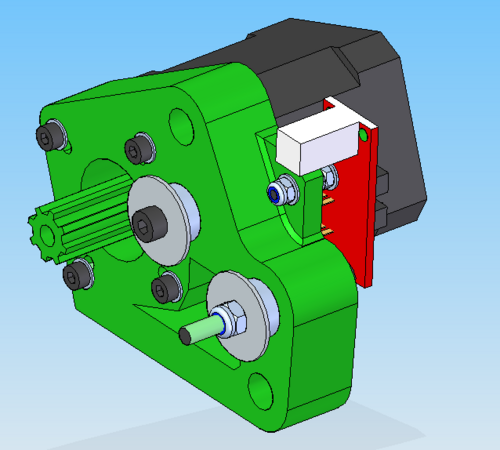

Motor bracket

BOM

Total # of assemblies: 1

| Name | Qty/assembly | Total Qty | Type |

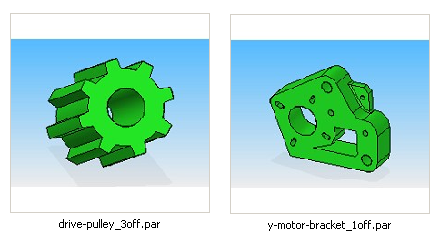

| drive-pulley_3off (alternative #1 #2 #3) | 1 | 1 | RP |

| y-motor-bracket_1off | 1 | 1 | RP |

| opto-endstop-v2-1-pcb | 1 | 1 | PCB |

| m3-capx20 | 5 | 5 | Fastener |

| m3-nut | 2 | 2 | Fastener |

| m3-nylock | 1 | 1 | Fastener |

| m3-washer | 8 | 8 | Fastener |

| 624-bearing | 2 | 2 | Bearing |

| m4-nylock | 2 | 2 | Fastener |

| m4-washer | 6 | 6 | Fastener |

| m4x40-cap | 2 | 2 | Fastener |

| m5-mudguard-washer | 2 | 2 | Fastener |

| stepper-motor-nema17-fl42sth47-1684A-01 | 1 | 1 | Motor |

Printed parts

Assembly

Optoswitch pcb is spaced with two M3 nuts. If your optoswitch connector is on the other side of the PCB to that shown here, turn the board over so that the connector is at the bottom. The M3 screw still goes through the hole nearest the middle of the board.

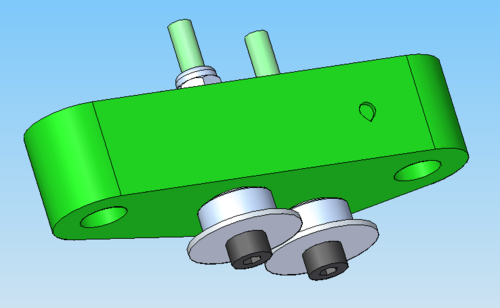

Idler bracket

BOM

Total # of assemblies: 1

| Name | Qty/assembly | Total Qty | Type |

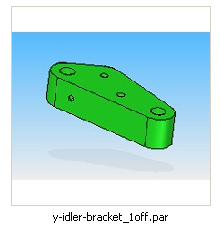

| y-idler-bracket_1off | 1 | 1 | RP |

| 624-bearing | 2 | 2 | Bearing |

| m4-nylock | 2 | 2 | Fastener |

| m4-washer | 6 | 6 | Fastener |

| m4x40-cap | 2 | 2 | Fastener |

| m5-mudguard-washer | 2 | 2 | Fastener |

Printed parts

Assembly

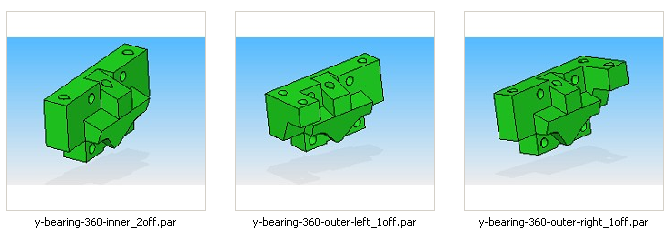

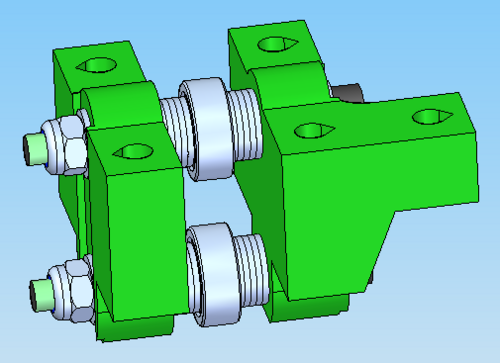

Y bearing 360

Two pairs needed, one with a ‘left’ outer and the other with a ‘right’ outer.

BOM

Total # of assemblies: 2

| Name | Qty/assembly | Total Qty | Type |

| y-bearing-360-inner_2off | 1 | 2 | RP |

| y-bearing-360-outer-left_1off | 1/0 | 1 | RP |

| y-bearing-360-outer-right_1off | 0/1 | 1 | RP |

| 624-bearing | 4 | 8 | Bearing |

| m4-nylock | 6 | 12 | Fastener |

| m4-washer | 28 | 56 | Fastener |

| m4x40-cap | 6 | 12 | Fastener |

Printed parts

Assembly

Before this assembly it's important to understand the key mechanical concepts of how the axes work. If you haven't already, check this video out:

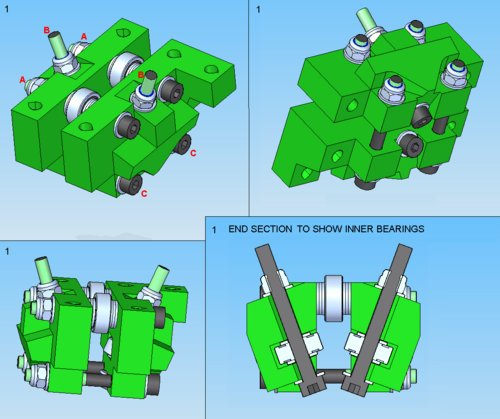

The Y axis is adjusted on the machine to get the bearings running true. The adjustment is accomplished by a number of the screws that hold it together. The picture immediately below shows the axis as assembled, but before it is put on the machine. The nuts with the red spots should be tight. All the others should be loose to allow adjustment.

While you are assembling these, check that the internal bearing (on screw 'B' below) can rotate freely and does not rub on the back of the reprapped part. If it does rub, take it out and scrape away a little of the plastic at the back with the point of a blade.

Once assembled, clamp the ‘A’ and ‘B’ bolts tight. Set the 360° fit by inserting a ø8 mm bar (e.g. Y bar) into the bearing assembly. Initially, there should be about a half-mm gap between it and the bottom two bearings when the bar is running on the top two. If this is tight, add extra washers either side of the top two bearings; if it is too loose take some away.

When the entire assembly is complete (see below) you will tighten/slacken the two lower adjuster bolts (‘C’) until all the bearings just touch the rod and smooth running is achieved.

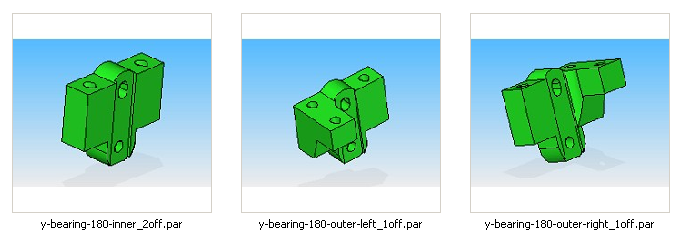

Y bearing 180

Two pairs needed, one with a ‘left’ outer and the other with a ‘right’ outer.

BOM

Total # of assemblies: 2

| Name | Qty/assembly | Total Qty | Type |

| y-bearing-180-inner_2off | 1 | 2 | RP |

| y-bearing-180-outer-left_1off | 1/0 | 1 | RP |

| y-bearing-180-outer-right_1off | 0/1 | 1 | RP |

| 624-bearing | 2 | 4 | Bearing |

| m4-nylock | 2 | 4 | Fastener |

| m4-washer | 24 | 48 | Fastener |

| m4x40-cap | 2 | 4 | Fastener |

Printed parts

Assembly

5 washer stack either side of bearing. Once assembled, insert a ø 8 mm bar in between the bearings and clamp the slotted bolt to achieve a smooth run. Ensure all bearings rotate when the bar is slid up and down.

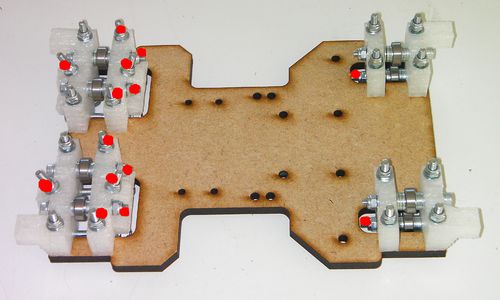

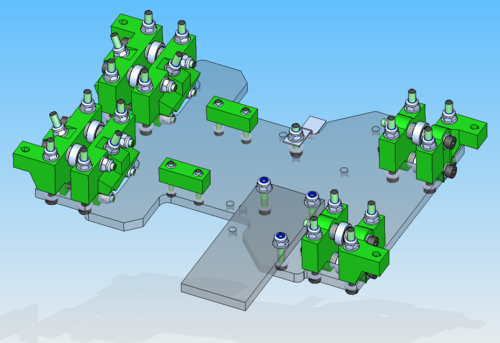

Chassis

BOM

Total # of assemblies: 1

| Name | Qty/assembly | Total Qty | Type |

| purge-plate | 1 | 1 | Sheet Image, DXF |

| y-chassis | 1 | 1 | Sheet Image, DXF, PDF (8.5x11), SVG |

| y-flag | 1 | 1 | Thin sheet |

| y-belt-clamp_2off | 2 | 2 | RP |

| y-bearing-180-left | 1 | 1 | Assembly |

| y-bearing-180-right | 1 | 1 | Assembly |

| y-bearing-360-left | 1 | 1 | Assembly |

| y-bearing-360-right | 1 | 1 | Assembly |

| m3-capx20 | 4 | 4 | Fastener |

| m3-nut | 4 | 4 | Fastener |

| m3-washer | 4 | 4 | Fastener |

| m4-nylock | 20 | 20 | Fastener |

| m4-washer | 40 | 40 | Fastener |

| m4x16-cap | 4 | 4 | Fastener |

| m4x40-cap | 16 | 16 | Fastener |

Printed parts

Assembly

Ensure all bolt heads sit on the underside of the chassis and bolt shanks point up. This guarantees that the chassis assembly will not collide with any of the frame structure it moves in.

Put the Y-axis ground rods through the bearings before tightening them. This ensures everything is aligned.

Bed will be attached later.

Back to Mendel mechanical construction root.