Metal Mendel

Release status: unknown

| Description | efforts towards a metal Mendel RepStrap

|

| License | |

| Author | |

| Contributors | |

| Based-on | |

| Categories | |

| CAD Models | |

| External Link |

Contents

Context

Note: Mendel is optimized to be printed. Eiffel, ORE-Bot, and the T-Slot bots are optimized to be made from metal. If you're making a machine from metal, consider one of those, or perhap an aluminum WolfStrap. And then make a Mendel from metal anyway, for aesthetics and love of the art. --Sebastien Bailard 03:26, 22 July 2010 (UTC)

Working Notes

Project Lead(s): swighton et. al.

Follow ups: thenoviceoof

Wiki-maintainers and Helpers:

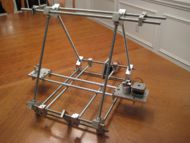

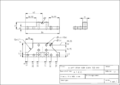

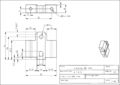

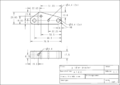

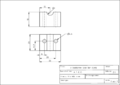

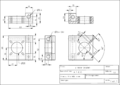

Photos and Drawings

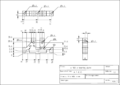

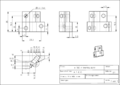

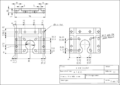

The photos below appear to be blueprints for the 3D printable parts on Mendel. If you can machine the parts below out of aluminum, you can almost build a regular Mendel. The other parts you'd have to get would be the gears that go on the motors. I have no idea where you could get or make those. Also, I know for sure I saw a printed part somewhere on Mendel that acts like a spring. That would have to be replaced with a metal spring.

Notes on the part blueprints

- all units are in millimeters.

- the little circle thing with the line through it means hole diameter.

- frame_vertex_diag notes:

- seems to have an unnecessary hole through the middle

- missing width measurements - has to be trigged out

- Mendel Part Diagrams

It addition to the above prints, there is a bunch of PDFs I found on this website in the zip file File:Mendel Drawings.zip. All units are in inches, with the occasional metric drill size. At first glance, they seem to be the same as the above pictures but on close inspection, they're a little different and some parts are missing.

Note

Metal/Mendel is cross-fertile with Eiffel and is probably part RBS. It's one big whirling gyre of intercompatible design concepts. Forum thread: http://dev.forums.reprap.org/read.php?4,29852,29852

Version 1 Errata

- Corner bracket depth is 0.8 inches

- x-axis belt clamp holes are tapped 2-56 and drilled for clearance of 2-56 screws

- x-axis carriage bottom width is 2.362" wide

- y-axis pulley block is 5/16" thick (not critical)

Tooling

You'll want a drill press, band saw, and lathe at minimum. Having a mill and cold saw are also nice.

Some drill numbers are not marked on the swighton's drawings (for those imperial unit users keeping up), so you'll have to reverse engineer them. Some are easy, like .375, while some aren't, and you'll have to guess. Choose the nearest drill size you have.

Process

The process is depends pretty heavily on having access to a machine shop and a bunch of metal: if you are using swighton's drawings, then you can probably get by with a bandsaw, drill press, and a lathe: having a mill and a coldsaw are also nice.

Basics of Machining in 5 Minutes

Insert vehement disclaimers here.

Drill Press: Secure your piece with some space/wood beneath it. Mark the piece with a point and hammer, or go in first with a center drill (this is so the drill won't 'walk' as much). Gently push the drill down into the piece, sometimes reversing to break off the fluff or clear the drill. When using bigger drills, be sure to slow down the drill speed.

Bandsaw: Push the piece through the blade. Use a proxy (such as a wood block) if the piece is small. Usually use it for rough cuts.

Lathe: Center the piece, usually some sort of rod, and move the cutter around.

Mill: Secure the piece, ensuring it is flat, and go over it a few times to shave material.

Flat

To create a part, first, you take a hunk of aluminum of the thickness that you want. If you don't have some of the desired thickness, then you'll have to take a coldsaw or bandsaw and cut your hunk down into the thickness you need. To get a good, flat piece, then you might want to go over it with a mill or a fly cutter. You might also want to square out the piece with a mill.

After getting a nice, square, flat piece, then you usually will drill all the holes, and tap the holes that need to be tapped.

If the final shape is not square, then you usually just want to mill it out.

360-bearing

Using the lathe, center a rod, and cut it down to the desired diameter. Drill out the center hole on the lathe, bandsaw it to the desired height, and mill out the notches. Drill the rest of the holes, with some counter-sink mill jobs.

Notes

Swighton's got a pretty good writeup, so he'll probably just copy it here. But don't hold your breath, he's a very busy guy. Feel free to ask him questions through his blog, though.