Development:RapMan Patches

Please do not add to this page. (It is slightly overcrowded as it is.)

This Page Contains multiple RepRap development projects and should be split up. Each individual project/design/improvement should have its own development page within an encompassing category.

| Description | Various patches for the RapMan RepStrap.

|

| License | |

| Author | |

| Contributors | |

| Based-on | |

| Categories | |

| CAD Models | |

| External Link |

Rapman is a most ingenious Repstrap kit so my thanks and congratulations go to the BfB development team! Thanks god there is still some room for improvements … would not be half as much fun without!

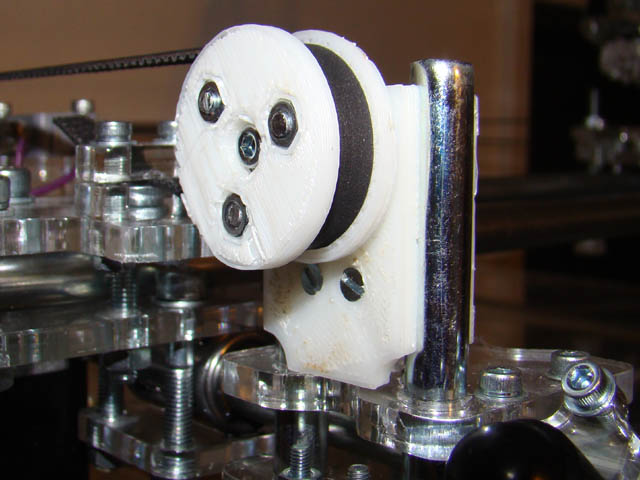

If you experience problems every other day with your printer producing parts like the upper one in the picture below (a replacement for the acrylic 10107) the reason may be the washers in the y-axis, which are fixed relative to timing belt and ball bearing.

So here is my solution to the problem, printed on rapman

I also have successfully fitted the z-axis with a similar solution.

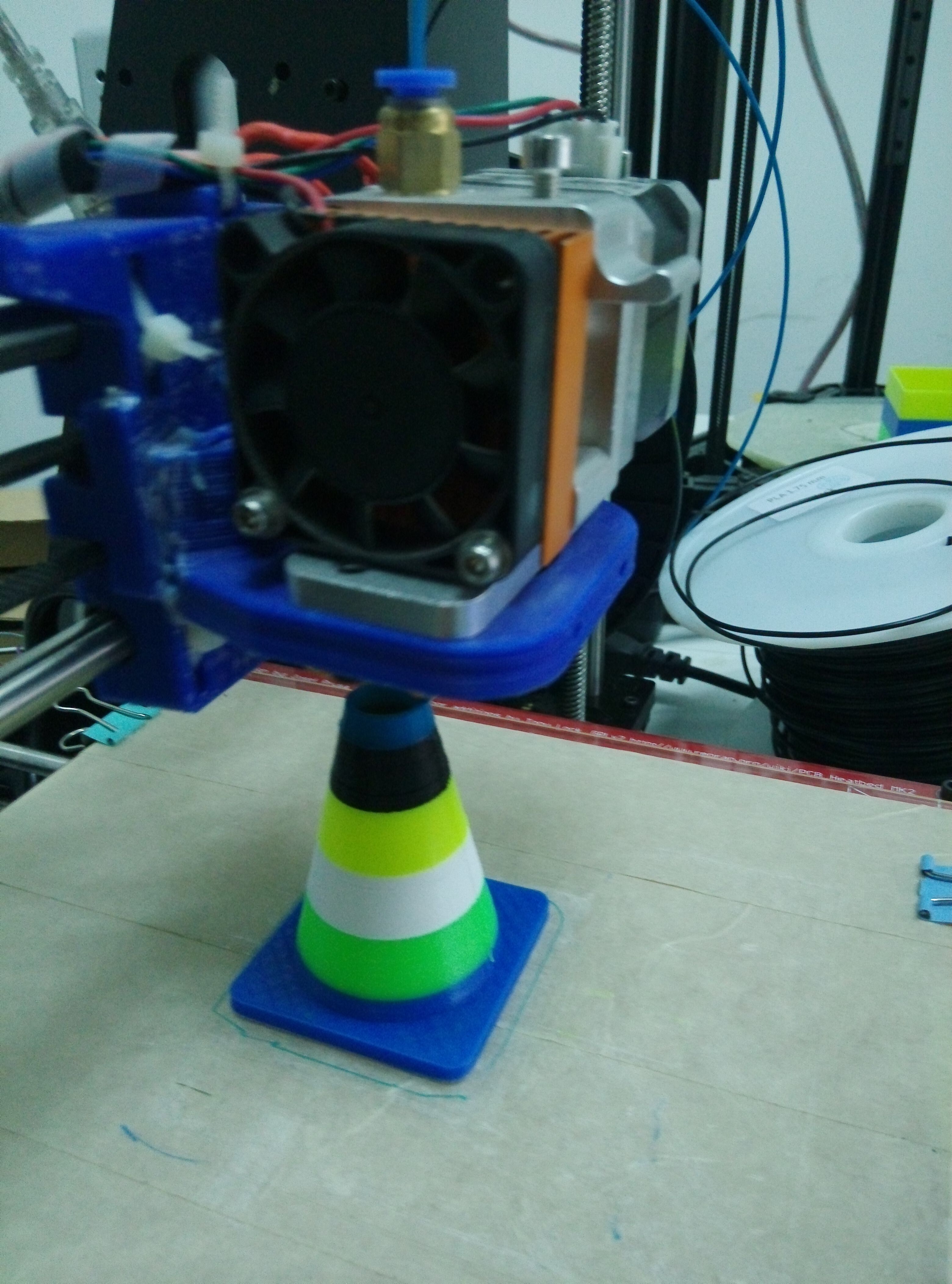

Also don't fall in despair if suddenly ABS mushrooms appear on your extruder nozzle like the one shown below after a few prints:

Let you inspire by the latest findings of nophead et al and try your luck with your own creation. Hint: try to avoid PTFE and PEEK, these are thermoPLASTS, so not really mechanically stable at temperatures an ABS extruder works. The body is essentially an M6 stainless filament guide tightly screwed to an aluminum nozzle with an integrated 7W high temperature resistor and thermistor. It is working for more than 100 parts now. Keep the aluminum part compact (i.e. max height 8 mm) and you will have no problem!