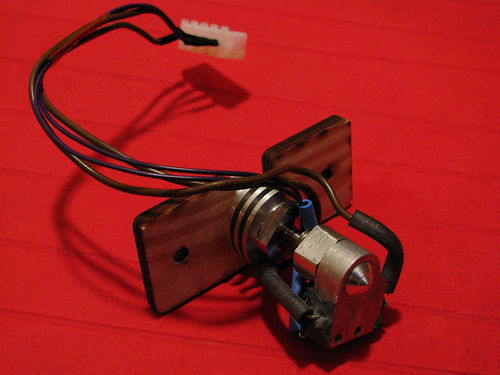

Arcol.hu Hot-End Version 4

Release status: working

| Description | An all-metal Wade-compatible hot-end

|

| License | unspecified

|

| Author | |

| Contributors | |

| Based-on | |

| Categories | |

| CAD Models | |

| External Link |

Contents

OpenSCAD Files

| IMAGE | FILE | DESCRIPTION |

|---|---|---|

|

arcolv4.scad | This is an openSCAD model of the hot end |

Main features

- All metal, robust to over-heating

- Compact

- Exchangable nozzle provided ptfe tape is used around the threads.

Original Informations

Original blogpost on blog.arcol.hu

Hot End

Hot end of this extruder consist of 4 parts.

- Nozzle

- Heater block

- Heating element

- Temperature probe

Nozzle

Nozzle is made out of aluminium and comes with 0.35 and 0.5mm orifice. The outside of the nozzle is threaded so it can be easily screwed into the heater block.

There are 2 important features of this nozzle

- orifice

- threads to attach rest of the extruder

Orifice on this extruder is "long". Much longer then on standard extruders. The reason for the short orifice channel usually is that it is very hard to drill long hole with a very small drill. Drilling 0.35mm hole 2mm in length is a seriously nasty task that requires special tools. What this feature provides is zero turbulence. If we go back to basics of fluid dynamics we'll find that to remove turbulence caused by pushing liquid trough reduced diameter pipe length of the pipe must be 5 times longer then radius of the pipe. This means that if we need to completely remove turbulence for 0.35mm nozzle we have to have 0.35mm channel be at least 1.75mm long, and for 0.5mm nozzle we need this to be 2.5mm. As same piece is used for both the 2mm channel length is selected. There is a downside to this long channel too. The longer channel increases the force needed for the filament to be extruded, but considering that other design choices reduced the force needed my opinion is that this is worth it.

The acceptor on the nozzle is threaded with self-closing thread - M10x1

Heater block

Heater block is just a piece of aluminium 10mm thick with a threaded hole for nozzle and 2 smooth holes, one for heating element and another for temperature probe

Heating element

Heating element used is 4R7 5W axial resistor.

Temperature probe

Depending on the electronics you use this extruder with, you need to use appropriate temperature probe. If you use it with RapMan you need GT204 100K NTC, if you use standard genX you need 200K NTC, some custom electronics use J or K type thermocouples ...

PTFE

PTFE tube goes into the heatsink.

Steel heat barrier

Steel barrier act like a barrier to prevent heat rising from the heater.

Heat Sink

Aluminium heat sink.