3-D printable photovoltaic module spacer

|

By Michigan Tech's Open Sustainability Technology Lab.

Wanted: Students to make a distributed future with solar-powered open-source RepRap 3-D printing and recyclebot recycling. |

|

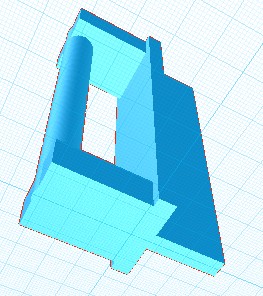

RepRap 3-D printing has already been shown to be a versatile tool for fabricating novel photovoltaic racking designs, however, they can also be useful for installing conventional PV modules on conventional racking. In order to ensure appropriate spacing and well oriented array these open-source photovoltaic spacers can be printed. The design has been created to be parametric in OpenSCAD so this design can be used for any conventional array.

The concept and testing of the design was performed by SolarUP

The device is 100% 3-D printable and should be printed with a reasonable infill as this is a tool that will be used on a construction site. PLA is fine although other materials can be used.

Source Code

OpenSCAD

You can help Appropedia by contributing to the next step in this OSAT's.

All measurements in mm

- s=6.35; //1/4 inch spacing

- l=12.7; // 1/2 inch lip

- d=25.5; // 1 inch down

- x=127; //5 inch length

- $fn=100;

- union(){

- cube([l+l+s,s,x], center=true); //lip

- translate([0,-d/2-s/2,0])cube([s,d,x], center=true); //spacer

- translate([0,d+5,0])cylinder(r=s, h=x, center=true);// handle

- translate([0,d/1.5,d*2.25-.25])cube([d,1.5*d,d/2], center=true);// handle connector

- translate([0,d/1.5,-d*2.25+.25])cube([d,1.5*d,d/2], center=true);// handle connector

- }