Wildseyed Simple Hot End

Release status: Working

| Description | Wildseyed Simple Hot End

|

| License | GPL

|

| Author | |

| Contributors | |

| Based-on | [[]]

|

| Categories | |

| CAD Models | |

| External Link |

Design Goals

When I began building my first RepRap, I found that many of you were experiencing problems with the hot ends, either because of design flaws, or the difficulty of manufacturing. I then convinced myself that there was plenty of room for improvement. I began with the following goals to guide me:

- Simple construction with readily available tools and materials

- Reliability

- Easy Maintenance

- Low Cost

Tools Required

- Drill Press

- Drill Bits

- Hack Saw

- Tap and Die Set

- Large Pliers or Vice Grips

- Flat File

- Caliper

- Scissors

- Soldering Iron

- Barrel Crimp Tool

- Small Brush or Cotton Swab

Materials Required

- Aluminum Block - 1" x 1/2" x 1/2" (LxWxH)

- Brass Coupling - Air Hose Type Female 1/4"

- Copper MIG Type Welder Tip - 0.025/0.6mm

- Set Screws - M4x5mm(1), M4x10mm(4)

- PTFE Rod - 1.5" x 1/2" (L x D)

- Thermistor - 100k, Glass Bead

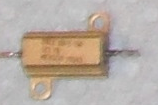

- Power Resistor - Aluminum Encased, Dale 5 Ohm 1% 5 Watt

- Kapton Tape

- Emergency Tape

- Heat Sink Compound

- Crimp-on barrel connectors - Small

- Small Alligator clips

- Insulated Wire - Teflon preffered, but any will do

- Plastic Ties

Assembly in Seven Easy Steps

- The Aluminum Block

- The Brass Coupling

- The MIG Welder Tip

- The PTFE Rod

- The Thermistor

- The Power Resistor

- The Wraps

Step One - The Aluminum Block

Using a punch, and a 5/16" bit, drill a hole through all, from the top of the aluminum block. The hole should be equi-distant from the three nearest edges. For example, if the block's top dimensions are 1" x 1/2", the the hole should be centered at 1/4" x 1/4". Next, widen the top half of the 5/16" hole using a 7/16" bit. Finally, use a M3.5 bit to drill a hole for the set screw. Tap it with a M4 bit.

Note: When drilling the aluminum block on a drill press, holding the block using pliers will help eliminate troublesome vibrations.

Step Two - The Brass Coupling

Drill down through the small end with a 7/32" bit to widen the opening. Drill down again, but only half way, using a 1/4" bit. This will allow the MIG welder tip to slip onto the coupling freely, but still provide grip when press fit later.

Step Three - The MIG Welder Tip

When the small opening of the coupling has been widened, insert the MIG welder tip into the coupling, and place it on a hard, smooth surface, or anvil.

Making sure that the MIG tip and coupling are aligned, use a smooth-faced hammer to tap the MIG tip into the coupling. It should only take three or four strikes to accomplish this step. Observe that the MIG tip hole gets smaller with each hit. Resist the urge to make really tiny holes. This will usually result in a clogged tip.

Once the MIG tip is attached, mount the male coupling in the drill press, and screw the female brass coupling onto it. Using the flat file and drill press, grind away the MIG tip at 45 degrees, until the taper produces a fine tip with a small flat surrounding the extrusion hole.

Step Four - The PTFE Rod

Cut the rod to length (40mm - 45mm). Insert into the drill press and drill a 3mm hole through all. While still attached to the drill press

Step Five - The Thermistor

The thermistor is the most likely cause of failure in any hot end. It is very fragile, and subject to shorts if not installed properly. Careful installation will ensure reliable operation, and accurate temperature measurements.

For this step, you will need a 100k Thermistor, and several lengths of Kapton tape. The goal is to encase the thermistor in several layers of capton tape, to insure that the leeds are insulated and supported, while still exposing as much of the glass bead as possible to direct contact with the heated surface.

Step Six - The Power Resistor

in progress...

Step Seven - The Wrap

in progress...