Volumetric Dimension settings

Overview

Skeinforge 40 introduced some changes based on the Volumetric 5D skeinforge plugin. With 40, skeinforge calculates how much plastic, by volume, is entering the top of the extruder per step, and therefore how much plastic is being pushed out the nozzle per step.

In other words, if 1 cm^3 enters the extruder, 1 cm^3 must exit the extruder.

(Some plastics like ABS don't appear to have a 1:1 relationship. There is ongoing research into why this is. 'Packing density' must be lowered for ABS)

The packing density could be a result of the melt density probably.. Have a look here: http://www.stelray.com/density_val.htm and http://www.natureworksllc.com/Technical-Resources/~/media/Technical_Resources/Properties_Documents/PropertiesDocument_Engineering-Properties_pdf.pdf (I dont have ABS for testing but I have inserted the ratio of molten density to regular density into FDPR and it looks good for the moment...(PLA))

So now we don't need to change feed/flow rate in order to get good prints. all we need to know is how much plastic is entering the extruder.

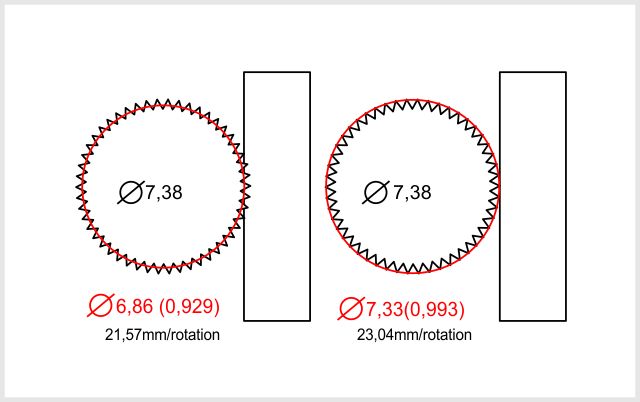

The biggest change that must be made is recalculating your E_steps_per_mm firmware setting. You need to know how many steps it takes to move the feedstock 1mm into the top of your extruder.

Basic Formula

Here's the basic formula:

micro steps per rev * gear ratio / ( pinch wheel diameter * pi)

- gear ratio: 39/11

- pinch wheel: 8mm hobbed bolt. probably between 7-5 mm

Accessible Wade's by GregFrost

- gear Ratio: 43/10

- pinch wheel: 8mm hobbed bolt. probably between 7-5 mm

- gear ratio: 59/11

- pinch wheel: 7mm

- gear ratio: 43/13

- pinch wheel: 8mm hobbed bolt. probably between 7-5 mm

- gear ratio: 31/11?

- pinch wheel: 8mm hobbed bolt. probably between 7-5 mm

Base values for comparison

Please list your e_steps_per_mm below, so that other reprappers have a data point for comparison:

- Wades w/ .9 degree stepper x 8 microstepping: 722 steps/mm --Buback 15:58, 15 March 2011 (UTC)

- Mendel Parts mendel : 367.355 (actually this is exact the half of what gives correct dimensions in Repsnapper (E.g extrude 10 extrudes 5mm but in skeinforge you can set flowrate same as feedrate then..) Try both settings (367.355 and 734.710 and see..)

- Wades w/ 1.8 degree stepper x 2 microstepping, and 75/9 ratio gears: 79 steps/mm. More details. --Ketil 22 March 2011

- Wades w/ 1.8 degree stepper x 16 microstepping, 39/11 gear ratio, dremelled (16x) bolt: calculated value 462.996 steps per mm. Experimentally determined value with 4042D yellow PLA: 503.443 steps per mm ~~Lanthan 03 August 2011

- Gen3 Tech Zone Remix. Wades: 140 steps/mm (not perfect). Adrians: 166 steps/mm Greg's Hinged Accessible Extruder: 165.24 steps/mm --Nudel 12:10, 23 May 2011 (UTC)

- Greg-wade with hobbed bolt, on FiveD Firmware : 619 step/mm experimentally found but without the hotend mounted (to don't waste plastic, and it worked) --Emmanuel 11:07, 4 August 2011 (UTC)

- Orca-V9 direct drive, on : 141 step/mm experimentally found by moving 100mm and 50mm --Emmanuel 11:07, 4 August 2011 (UTC)

- Greg-wade with hobbed bolt, on Marlin Firmware : 325,79 step/mm experimentally found --Emmanuel 13:25, 19 August 2011 (UTC)

- Techzone Huxley with Techzone monotronics - bowden cable extruder with huge wooden lasercut gear #define E0_STEPS_PER_MM 15.35 experimentally found by moving 100mm --Deuxvis 15:13, 9 October 2011

- MakerGear Mendel Prusa kit: 1258 step/mm experimentally found by moving 100mm and 500mm --Affy, May 15th, 2012