TinyCut

|

English • العربية • български • català • čeština • Deutsch • Ελληνικά • español • فارسی • français • hrvatski • magyar • italiano • română • 日本語 • 한국어 • lietuvių • Nederlands • norsk • polski • português • русский • Türkçe • українська • 中文(中国大陆) • 中文(台灣) • עברית • azərbaycanca • |

Release status: concept

| Description | a tansportable laser cutter

|

| License | |

| Author | |

| Contributors | |

| Based-on | |

| Categories | Laser

|

| CAD Models | |

| External Link |

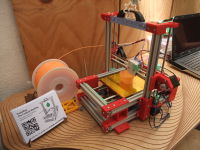

Now school project we want to develop, a transportable laser cutter. We base our work on the FoldaRap2 because we work in the same lab as Emmanuel.

Goals of this project: We want to develop this machine using off-the-shelves parts or existing projects and technologies. We want to be able in this project to create a tiny laser cut portable in less than 4 month.

Contents

Concurrence

Concurrence

With 600€ you go to an small laser cut http://www.ebay.fr/itm/High-Precise-and-High-Speed-USB-CO2-Laser-Engraver-Engraving-Cutting-Machine-/170934801974?pt=LH_DefaultDomain_3&hash=item27cc821636

Specifications

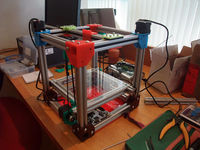

- Printed Parts: 20-21

- Non-Printed Parts: Laser tube, Power laser, optical part, laser water cooling, air boost,

- Cost: 400 €

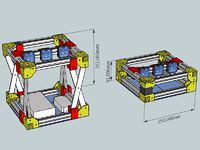

- Cutting Size: 200mm x 200mm

- Resolution : a voir ?? mm and ?? mm

- Speed: ?? mm/s

Special Features

- Mobile!

- Modular

- Innovative

- Based on standard/cheap 20x20mm aluminium extrusion (with 6mm slot)

- Easy to build, with few tools (the printed parts are based on a 20mm grid (for overall aesthetic and mostly to ease the design), are generally 3-4mm thick, and fit the beams in a way you have nothing to measure during the assembly

- Whith a real CO2 laser tube

- Little (the entire machine is going to be about 30*30*30)

- Big RED Power Security (my favorite detail ^^)

- Cut surface about 200 x 200 mm

- Easy to place on the material (it the machine witch go on the material, not the material witch go inside the small machine)

R&D

notre facebook

Inspiration

Some details that I found interesting or related or want to integrate to this idea of a portable laser cutter ...

External links, media/press, etc.

We like feedback from the community:

- marinosaurus page mention to be doing this project.

- User:Marinosaurus

History // forecast

- 2013/02: beginning

- 2013/03: Bills of materials, sourcing, buying

- 2013/04: Developing CO2 and printing test, Receving the part.

- 2013/05: Assembling work, and presentation of the project for our school.