TRap

Release status: unknown

| Description | Documentation of TRap development

|

| License | |

| Author | |

| Contributors | |

| Based-on | |

| Categories | |

| CAD Models | |

| External Link |

The TRap will be an alternate mechanical structure for the reprap project. Team TRap intends to make it an entry in the Kartik M. Gada Personal Manufacturing Prize. Before I go any further, I want to thank Team Columbus: I have used Isaac's basic layout for this page.

Contents

Overview

The Gada Prize

The main requirements of the Gada Prize are:

- Print at least three different materials, including one that is usefully electrically conductive.

- Demonstrate the ability to print electronic circuit boards.

- Any print beds must be of a material which may be reused with minimal refurbishment for at least 20 print cycles.

- Maintain a total materials and parts cost under $200.

- 90% of the volume of the device's components shall be printed.

- Demonstrate a build volume greater than 300mm[11.81in] x 300mm[11.81in] x 100mm[3.94in].

- The capacity to print a full set of components for a complete replica of itself within 10 days unattended save for clearing no more than one printer head jam.

- The ability to print autonomously without a PC attached.

- Uses no more than 60 watts of electrical power.

Current Status

I am currently brainstorming various ideas and configurations for use in the TRap.

Current Challenges

- I need a couple of team members. I could use a builder and a control person/programmer, but I don't think I'd turn down help from any interested party.

TRap Specifications

The table below outlines the specifications of the machine.

| Metric[Imperial] | |

|---|---|

| Manufacturer | Anyone |

| Model | TRap |

| Technology | FFF (Fused Filament Fabrication)/Thermoplastic extrusion |

| Price of all materials | TBD |

| Annual Service Cost | TBD |

| Size | 400mm[15.75in] x 400mm[15.75in] x TBDmm[TBDin] |

| Weight | TBDkg[TBDlbs] |

| Build Envelope | 300mm[11.81in] x 300mm[11.81in] x TBDmm[TBDin] |

| Materials | TBD |

| Material Cost | TBD |

| Speed | TBD |

| Accuracy | TBD |

| Finish | TBD |

| Volume of printed parts to replicate | TBD |

Design Philosophy

- The TRap will make use of a parallel manipulator

- The number of unique parts shall be kept to a minimum

- Parts shall be made as simple as possible

- Identical parts will be used wherever possible

- Orthogonality shall be preserved wherever possible

- Non printed parts shall be "Off-the-Shelf" (OTS) whenever possible

- Substitution of similar OTS parts should require a minimum number of changes to the design (i.e. a change of bearing size)

Nomenclature

Key Concepts

- Parallel Manipulator

Structure

- Concept 1 is out! see work log below.

Print Bed

Axes

- 3 Identical Axes assemblies

Extruder

- TBD, possibly Bowden due to the light weight.

- Eventually, a three material extruder needs to be developed.

Control Systems

- TBD, this will not be a trivial problem

Workbook

2010 September 01

- Registered team on the RepRap wiki

- Started concept generation

2010 September 02

- Created this wiki page; thanks again to Team Columbus, who provided the format.

2010 September 03

- Finished mocking up Concept 1.

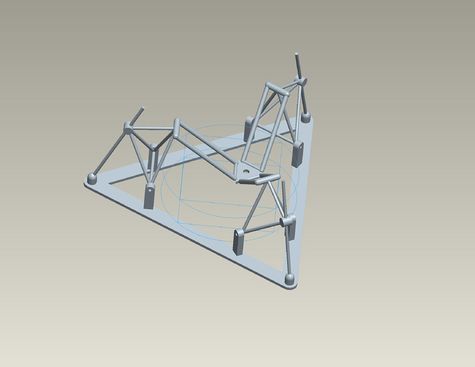

This is worth taking some time to explain. TRap is a manipulator with a parallel kinematic chain. I am using a variation on the normal delta robot design that is most often seen in "Pick-and-place" robots. This design approach has two major advantages: it can be very fast, as the arms manipulator platform has a very low intertia (servos are all stationary); and all three axes are totally identical, reducing part count. The major disadvantage is that the control problem is not trivial: getting the end effector to move with constant velocity along a straight line involves all three servos.

The major parts of this design are:

- Base Plate: This is easily the largest part, and will have to be split into several different (preferably identical) parts to be printable. In this concept, the build surface is not part of the baseplate, but can be places on top or, or underneath the base plate. This will probably change as the design is fleshed out more.

- Motorized axes: These are shown much simplified, and the details still need to be worked out. The gist of it is that they will pivot around their attachment to the base plate, and they will act to move one vertex of a tetrahedron.

- Tetrahedra: This is merely a force redirecting structure. It allows me to have much less structure than some other tripod designs. Three are required.

- Arms: A length of printed plastic with a universal joint at each end. Six are required.

- Platform: This is where the extruder will live. One required.

Note: The blue lines on the sketch show the desired working envelope. As yet, things still need to be scaled a bit to avoid mechanical singularities.

General Notes

In accordance with the official Gada Prize rules regarding documentation and transparency - as interpreted by the RepRap Core Team and others - all documentation for this project will take place here in this wiki. If there happen to be any "Other Spaces" out there that have documentation for this project, then such information is posted there only after it is posted here.

- The following notes help to keep this workbook in a neat and orderly condition and shall be generally adhered to throughout all levels of documentation.

- All dimension and temperature nomenclature shall include both SI and Imperial units. SI units shall be first followed by Imperial units in brackets. Examples: 100mm[3.94in] and 40°C[104°F]