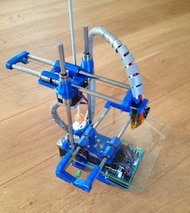

Smartrap mini

|

English • العربية • български • català • čeština • Deutsch • Ελληνικά • español • فارسی • français • hrvatski • magyar • italiano • română • 日本語 • 한국어 • lietuvių • Nederlands • norsk • polski • português • русский • Türkçe • українська • 中文(中国大陆) • 中文(台灣) • עברית • azərbaycanca • |

Smartrap Mini | How to Get Smartrap | Smartrap Build Manual | How to Use Smartrap | Smartrap Improvements

Release status: working

| Description | A small but strong RepRap designed to be really easy to build and maintain.

|

| License | |

| Author | |

| Contributors | |

| Based-on | |

| Categories | |

| CAD Models | |

| External Link |

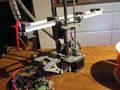

Video of version 0.3 printing. It's a little customized version. I removed the plate_X_bottom. It was straight enough eventually.

Note that there is now only 8 printed parts in this RepRap, which is great!

Vision: The Goal

This is a new design of a RepRap 3D printer. It is modeled after the Printrbot, designed by Brook Drumm, who is one of our best designers in my opinion. I tried to make the design it even simpler. (Maybe Brook would be up for a challenge? :) ) This design is made with mostly printed parts, so it's easy to reproduce. It's also full GPL, which means it's open for anyone to use.

The goal is for the Smartrap assembly to be easy enough for a 12-year-old to complete without complication. When assembling, the education part is very important. By building the Smartrap, the user should learn how each part is working in the system, so that the user will be able to find problems and fix them easily. In other words, the Smartrep will try to reach a wider audience of people who might not be ready to build more complicated models. The main goal is to help spread the word and introduce people into the world of replicative, DIY makers.

Other features in no order of importance are:

- Real Reprap: most of the structure should be printed, so it can easily print itself for machines. Only the common base should be bought at special shops (motors, hot end, controller, LM8UU linear bearings, endstops).

- Simpler assembly: There should be no need for special tooling, ultra precision cuts, drills or even adjustments. The ultimate goal would be an assembly with no screws, where (almost) everything snaps together in place.

- Open source!: Since it is GPL, you can build it, sell it, make a business of it etc. Everything is fine as long as you stay under the GPL licence.

- Cheap as possible: Currently working with fishing line, printed bushing(?) (not well working for me now), and less costly electronics (no heat bed, four motors, no fan).

- Optionally open to experimentation: I've tried so much configurations. For example, aluminium rails with 608zz, fixed axis with moving hot end, moving axis with fixed hot end, etc. (I should put them all online one day).

Features

Print size: From 150 x 150 x 150 to around 250 x 250 x 200. The first prototype is 200 x 200 x 150

PLA only: It's a political decision; even if ABS gives better results , the fumes and the ecological impact outweigh the pros. PLA can be composted and uses less power. (Open for discussion!)

Layer height: Not fully tested yet, but looks like 0.2 works well

Printed parts: 8

Screws: M6 x2, M3 x16

Non Printed parts: 6 smooth rods 8mm , 12 LM8UU, 1 M5 , 2 fishing lines 500mm , 4 nema17 motors, 1 hot-end j-head, 1 controller board , 3 mechanical end stops.

Assembly operations: There aren't many steps, but it's not entirely clear yet. Even though I've already assembled three versions, the process was not as smooth as it should be. The main design is ready, and we will now focus on details to make the assembly easier.

Practical Info: Tips and Tricks

Rod Lengths: Right now we have 90mm lost on the X axis and 70mm lost on the Y axis. It's too much, but I'm working on it for version 0.5. So if you want 200x200 you need 290mm rods on the X axis and 270mm rods on the Y axis.

For Z-Rods, the current recommendation is 250mm.

Gallery

- 045 4.png

Shorter plate_x, LM8 holders and new screw on Z axis for bed leveling