ScrewRap

This page is a development stub. Please enhance this page by adding information, cad files, nice big images, and well structured data!

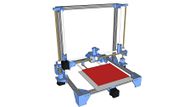

ScrewRap

Release status: Experimental

| Description | T-Slot reprap using leadscrews instead of belts

|

| License | unknown

|

| Author | |

| Contributors | |

| Based-on | [[]]

|

| Categories | |

| CAD Models | |

| External Link |

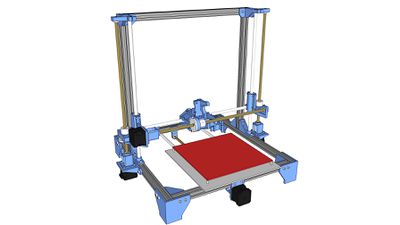

Design Goals

The following list summarise what the ScrewRap hopes to achieve:

- Minimal tools. I want assembly to be as easy as possible. The tools I'm thinking of are Allen (hex) keys, screwdrivers and maybe a drill. This list may increase as time goes on, but not by much.

- Cheap. Even though I'm using leadscrews, I still want the rest of the printer to be as cheap as possible.

- Accurate. To achieve this the design requires a sturdy frame and precise linear motion components.

- Easy to source. I want to avoid custom made parts as much as possible, and use standard parts such as T-Slot, Stepper motors, Bearings etc. Where specialised components are required they will be 3D printed. The leadscrews may be slightly more difficult in sourcing than the rest.

Specification

- Printed Parts: 37

- Non-Printed Parts: >88

- Material Cost: ?

- Cost: ?

- Printing Size: 250mm x 260mm x 280mm

- Resolution : XY = 6.25μm with 20mm pitch leadscrew; Z = 0.625μm with 2mm pitch leadscrew (1/16th microstepping assumed)

- Accuracy : 50μm positioning accuracy estimated

- Speed: ?

Parts list

Printed parts

TODO: Upload stl files, or use GitHub

| Part | Description | Quantity | Image |

|---|---|---|---|

| Top left support | 1 | ||

| Top right support | 1 | ||

| Z motor mount | 2 | ||

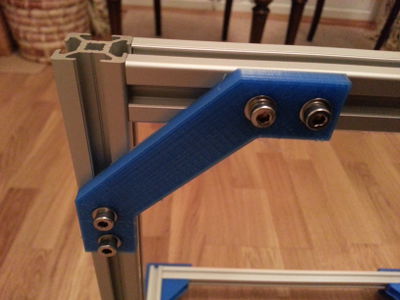

| Bearing holder | Holder for the Pillow bearings (or "skate" bearings) on all the axis motors | 4 | |

| Gantry brace | 2 | ||

| Z clamp | Clamp for the bottom of the Z smooth rod. Also includes opposite gantry brace | 2 | |

| Foot | 4 | ||

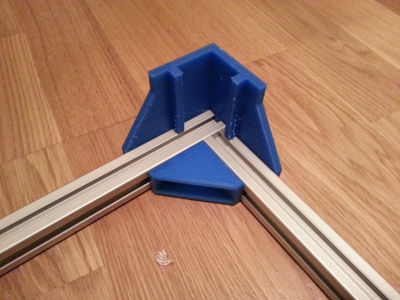

| Frame Brace | Corner braces for the lower frame | 4 | |

| Y clamp | Clamp for the Y smooth rods | 4 | |

| Y motor mount | 1 | ||

| Y bearing block | Holder for the Y axis pillow bearing. | 1 | |

| Y bearing holder | Holder for the Y axis linear bearings | 3 | |

| Y leadscrew nut holder | 1 | ||

| X end motor | 1 | ||

| X end idler | 1 | ||

| Z linear bearing clamp | 2 | ||

| Quickfit extruder | The Quickfit Extruder by RichRap | 1 | |

| Quickfit part A | The half of the quickfit mount with the leadscrew nut mount | 1 | |

| Quickfit part B | The other half of the quickfit mount | 1 |

Development

Here's a wall of photos showing the development of project. The top ones are newest.

Inspiration

The following list contains all the sources I've found inspiration or parts for this design (Currently incomplete):

- smartroad's Dual-Struder Fabricator. This is the foundation for my design, with everything else being built on top

- Jspark's Kid Mendel has the option to use leadscrews for all axes. He's also used threadless ballscrews which I may investigate in the future as a cheaper alternative.