SMT Pick-n-Place System

A SMT pick-and-place system is a machine that can be used as part of Automated Circuitry Making. To convert a RepRap 3d printer to be a multi-function machine has been the trend of another enthusiasm. There is a project known as OpenPnP. This machine picks up surface-mount electronics components and places them on a PCB (hopefully in the correct location and orientation).

A fully fledged SMT Pick-and-place system requires:

- Grippers or a picking toolhead (see below or see Gene Hacker's Pick and Place ToolHead)

- PCB holder(s) (see below this page)

- Component feeders

Optional subsystems include:

- Vision systems for compensating for variations in the pick-up of a component, and for detecting correct placement, calibrating against the circuit board dimensions, etc.

- paste Dispenser for placing solder paste on the PCB (although a squeegee and a solder paste stencil is probably faster if you're making more than one PCB)

- 3D printed holders

- Reflowing in-situ with a controlled hot-air stream.

- PCB changer systems

Code for this project can be found on Google Code, a project started by Erik De Brunjin.

FirePick Delta is intended to be a complete 3D printer that (more importantly) can , a project started by Neil Jansen, Karl Lew, Christian Lerchem, Thomas Kilbride, Dayton Pid, Dave Shanklin.

- FirePick Delta: $300 Pick and Place / 3D printer. Project logs at Hackaday.[1]

- FirePick Delta, the Open Source MicroFactory: Delta mechanism design and Frame construction.[2]

- FirePick discussion group.[3]

OpenPnP, the open-source pick-and-place project

Contents

Grabbing parts

Options are:

- Most gripper types rely on suction

- Mechanical grippers

- Ferromagentic parts (e.g. most resistors) can be grabbed with an electro-magnet.

Grippers

Vacuum grippers

Possible vacuum sources:

- A printed pump (such as this one by Madox, or this one)

- Peristaltic pump (such as Zach's)

- A positive pressure based on the Venturi-effect (can be printed)

- Simple off the shelf USB-vacuum

- A piston that is actuated with a motor (lego, fishertechnik, etc.).

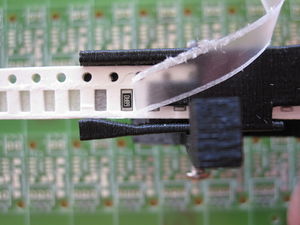

Rubber vacuum tips:

Mechanical grippers

Magnetic grippers

Pick-and-place machine made of printer, CD-ROM drive and floppy drive (Russian) Video (note: downloads a 8mb file)

Holding the PCB

- These kinds of studs with magnets are useful for holding PCBs.

It's pretty much impossible to repeatably hold the PCB at exactly the "correct" location. So most proprietary and most open-source pick-and-place systems rigidly clamp the PCB to some position within a few mm of the nominal "correct" position, then use machine vision algorithms to look at where the PCB actually is, and then compensate for small offsets and rotation of the PCB.

placing parts

After a person finishes a PCB layout, that person generates a bunch of "manufacturing files". One of those files lists, for each component on the board, an X,Y location and exactly what kind of component goes there. (It also lists the X,Y location of each fiducial.)

The pick-and-place machine goes to the component feeder holding exactly that kind of component, picks it up, and then moves to that X,Y location and puts it down. Simple, right?

Well, it doesn't go exactly to that X,Y location. Before picking up any parts, the pick-and-place machine moves to the X,Y location of each fiducial on the board, and uses a down camera -- rigidly mounted to the placement head -- to look at the board and measure the X,Y offset of each fiducial, which the machine uses to compensate for small offsets and rotation of the PCB. (This also helps prevent dropping a lot of parts on a board that is accidentally loaded upside down, or no board at all is loaded, or the wrong board is loaded in the machine, or the wrong manufacturing file is loaded for this particular board).

The down camera is also used to look for a part to pick up, so the machine can ask the humans for more parts when the part feeder or part tray is empty. After the part is found, the down camera looks at the top of the part and helps position the nozzle at the exact X,Y center of that part.

After picking up a part, many machines hold that part over an up-camera that looks at the bottom of the part (or holds it over a mirror that allows the down camera to see the bottom of the part as a reflection in the mirror, a virtual up-camera). Occasionally the machine discovers there is no part on the nozzle -- either it failed to actually pick up the part, or the part somehow fell off between the part feeder and the up-camera. (When this happens too often, the machine signals for some human to crank up the vacuum power or swap out a more appropriate pick-up tip or etc). Usually the up-camera sees that the part is not exactly centered on the tip, and has some unwanted rotation. The machine rotates the tip until the up-camera sees that the part is in the "correct" rotation. Then the machine uses the up-camera to figure out what X,Y compensation it needs to use to get the part to the correct location on the board.

After picking up and appropriately rotating a fine-pitch IC, the pick-and-place machine looks for the fiducials on the board *again* -- often the person who lays out the PCB puts 2 fiducials at 2 opposite corners of where the IC *should* go, which makes it easier for the machine to put that part in the correct location -- the geometric center of the part goes exactly at the geometric center of the 2 fiducials, etc. (compensated by the X,Y offset of the part on the nozzle as seen by the up-camera).

Other operations

Printing the component and work holders

To make the setup operations easier to perform accurately, the tool holders could be printed just before pick-n-place operations start. This ensures that the PCB is parallel to the XY plane of the cartesian bot.

Circuit making

If a circuit could be printed or milled in the same machine, this would save you setup time. This is discussed at: Pick-n-Place Feeders. See also: Printing electronics.

Reflow soldering

Usually reflow is done in a controlled oven and the temperature should follow a specific curve. This is to prevent sensitive devices such as LEDs from overheating and to still properly reflow the paste at every solder joint. However, I (Erik) have good experiences with a hot air stream that can be fed from the toolhead, meaning that you can also reflow the boards in the same machine. So far I've been using [this rework station] successfully.

Great resources

- RobotDigg OpenPnP

- Hack-a-day on Pick-n-place

- Adafruit's wiki

- OpenPnP, the mailing list for the open-source pick-and-place project

- Brian Dorey's DIY Pick and Place project blog; many of the hardware CNC files and software for this pick and place machine have been released under an open-source license at Brian Dorey's github account

- "Adafruit: SMT manufacturing" describes a variety of tools and tricks and shortcuts for putting parts on a PCB and taking them off.

- solder paste stencil tutorials.[4][5][6][7][8]