RepRapBreeding

Release status: Experimental

| Description | Documenting my simplification efforts of the Mendel

|

| License | unknown

|

| Author | |

| Contributors | |

| Based-on | |

| Categories | Mendel Development

|

| CAD Models | |

| External Link |

Description

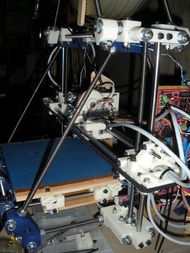

This page will document some changes I am planning to make to a version of Mendel that has the following properties:

- 1. as simple as possible, but no simpler

- 2. maximize build space

- 3. minimize print/construction time

- 4. minimize cost

The main focus is optimizing Mendel to increase possible reproduction rate while not losing any build volume and maybe increasing it. A big part of that focus will be simplicity (Not necessarily self-reproduction but ease of reproduction). Some quotes that inspire me:

- “Simplicity is the ultimate sophistication.” - Leonardo da Vinci

- “Everything should be made as simple as possible, but not simpler.” - Albert Einstein

- “Perfection is achieved, not when there is nothing more to add, but when there is nothing left to take away.” - Antoine de Saint-Exupery

Contents

Current Developments

File:RepRapBreeding Mendel-assembly-data-sheet.ods

Integrated Parametric RepRap

Mindel

Things Being Considered

This involves many designs already made by Vik and others currently working on the Mini-Mendel development. One area where I differ from the current Huxley/Mini-Mendel development is that there are certain design complexities in both that I would like to eliminate. (i.e. X-axis belt arrangement, all three axis bearings, etc...) It may involve some of the following:

- 1. reduction in number of bearings

- 2. adding more low cost ubiquitous vitamins

- R/C car gears for the extruder, springs for the bed, etc...

- (I know this is backwards from a lot of other development)

- 3. optimizing all parts for plastic volume, print time, etc...

- looking at fill patterns, hole shapes (square vs round), etc...

Related Links (what some others are doing along these lines)

- Vik's Mendel X & Z interface Bracket

- Vik's Mendel Simplified Y Bed

- Vik's Mendel Simplified Z Axis

- OpenSCAD rewrite of the Mendel Parts

- Prusa Mendel Remix

- RepRap Breeder: a similar attempt to design a fast-replicating RepRap from Spacexula

- Bonsai RepStrap: an attempt to make a fast-replicating RepRap with a much smaller build volume -- the two-stage lifecycle involves a tiny, highly portable RepRap that can be produced quickly, which produces a full-size Mendel as the next stage.