Recycler

Release status: experimental

| Description | research on recycling RepRap parts into powder and HDPE

|

| License | unknown

|

| Author | |

| Contributors | |

| Based-on | [[]]

|

| Categories | |

| CAD Models | |

| External Link |

Contents

Discussion

http://dev.forums.reprap.org/read.php?171,34188

Kitchen Food Processor

I've been thinking about trying a generic kitchen food processor - the appliance you use to turn 2 kg of carrots into shreds. I'll try it once I have a granule extruder built. --Sebastien Bailard 03:53, 22 February 2010 (UTC)

Freeze first

It may help to chill the plastic parts in a freezer first.

Lid System

Mason Jar

We can print a system that screws onto a large glass jar, or in some way uses a jar to store plastic.

Bucket

We can print a system that attaches to a large bucket.

Cyclonic System

If we're using a solid receptacle rather than a cloth bag, we may want to use a cyclonic-type seperator powered off a vacuum or tiny electric fan.

Crazy Talk

Cooling idea, requires compressed air feed. Probably unnecessary. http://en.wikipedia.org/wiki/Vortex_tube

Rotary Shaper

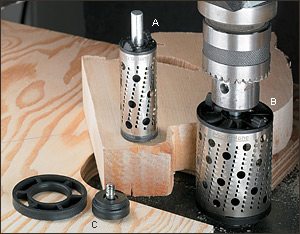

Forrest, if we can't solve the grit contamination issues with mechanical filtering, there's always a $10-15 microplane rotary tool that works with a drill press: http://www.leevalley.com/wood/page.aspx?c=1&p=53229&cat=1,42524

We can RepRap a machine built around the microplane rotary shaper and a corded drill, with an exhaust port. It would help to make it dishwasher proof.

Those rotary shapers are "discontinued - while stocks last" at that supplier. Maybe there's more milage in Surform plane blades which are cheaper and unlikely to disappear. The drawback is that they are flat, so would need a linear rasping/grating action. -MattyMatt

Old Paper Shredder

?

Grinder: Working Research Notes

I've got the curling on HDPE prints down to something quite manageable. Last night I decided that I could dress down the remainder if I only had a belt sander. A little while ago, I went into town and bought a nice little Makita belt sander. It wasn't the cheapest, but it would lay, belt-side-up, quite firmly, which is what I needed.

It took about 15 seconds to grind the raft off of Bogdan's corner block for Rapman and dress off a few other rough places.

I bought a new little drum sander for my Dremel {~$4.50} and cleaned up the seating for the z-axis bearing.

It also did a nice job cleaning up the hole for the z-axis threaded rod.

One added benefit which might be the Rapman or might be the HDPE or might be the Skeinforge settings is the roundness of the horizontal holes in the print.

None of this teardrop nonsense.

I'm beginning to think that HDPE is a very serious contender for printing Mendel parts. It's

- dirt cheap,

- readily available,

- strong,

- doesn't make nasty fumes

- AND now we know how to work with it.

I expect that polypropylene, which is cheaper still is going to be just about as good.

Now here is the serendipitous Christmas present. That Makita belt sander grinds HDPE a treat and puts it in a little bag, or a big one if you want to sew one.

Guess what? The problem of grinding plastic so that it can be recycled into filament has just gone away. Virtually any kind of extruder can eat plastic powder. It takes a heftier one to use 3 mm pellets or shreds of a similar size.

Build yourself a slope-sided hopper on top of that Makita and your grinding problems are solved. When you wear out your belt, go down to your hardware store and buy another. The Makita uses a 3" x 18" belt and it costs a bit over a dollar. No difficult-to-sharpen, never mind dangerous, macerating blades.

God Jul, everybody! :-D

(Writer: Forrest Higgs)