RBS

Contents

Working Notes

These are working notes, leading towards making models and then a formal proposal. It may be too early to talk this up in other places.

License

Documentation

This webpage, and more generally, the Library as a whole.

Action Items

- Ask Forrest to make 2 gears which mesh, and are both bolted to a perforated sheet of metal.

- Ask Forest to make up a set of pdf or SVG files I can use to make gears.

- Find a friendly laser cutter. I favor South End Boston Fab Lab because they can follow along.

- Make several hundred gears of all sizes.

- Make a 500 feet of plastic gridbeam using the CNC router at architecture.

- I want to move to an open source design system. I think blender is best because it is the open source modeling program with the most users and the biggest community.

- Prepare a proposal for the BRL-CAD people to design a gear-cad module for blender.

- First, see what has been done with blender.

- Eventually, may want benchtop jewelry-scale sheet bend and brake, to make my own RBS parts.

Motivation

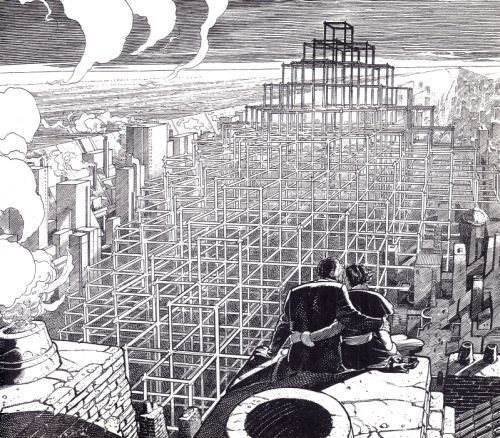

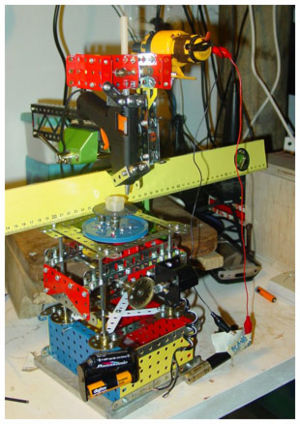

- Vik Olliver's Meccano-set based RepRap prototype.

- Merkur based apparatus for centrifugal casting of soft contact lenses by Otto Wichterle

- TriLap is an idea for making a RepRap using RBS for the parts.

Sourcing

Still an open question. Probably going to be Sebastien + drill press and jig.

RepRap Building System

This is a cross between grid-beam and old-fasioned erector_set, but we will make RepRaps and TriLaps from it.

The 'RepRap Building System', aka 'RBS', aka 'Building System' is made from grid-beam type perforated beams, store-bought fasteners, and RepRap-printed parts like gears and fittings to hold stepper motors and smooth rods.

For more information, see TriLap.

RBS is a key element in the Education RepRap Education Initiative. This will engage folk who work with their hands well, but are not computer oriented.

And it will be lots of fun.

Description

- TriLap will be a steel square-tube CNC router made with tri-lapping joints, aka Tri-Joints with Image:NEED-trijoint example.jpg Note that this is slightly similar to LumenLab's RogR, but will be cross-fertile with RepRap.

We can if we want try to extend this use of gridbeam and erector-set like technology into a TriLap/Building_System system that levrages RepRap to make lots of mechatronic systems using grid beam and grid sheet, and 3D printed gears, etc., but that's sort of beyond the scope of this project. (Step 2, technically)

Development Outline

- Make gears and beam to illustrate core concept.

- Sketch out a TriLap in gear and beam.

- Blog.

- Solicit domain experts for toy and model building systems. This means sending polite emails to Erector Set, Meccano, and Model Engineering geeks requesting critique. After further development, we will solicit user testing, i.e. 3rd graders and architecture students.

Motion Control

A:So what do you need? Besides a miracle. B: Gears. Lots of gears.

Entrepreneur-based research

If it is any good, we will have to make kits to test the ideas. This process will mean donating to 3rd graders. We have SETC fab lab do this; they are set up for it.

If you like this idea and want to get started, please buy a grid beam book.

Documentation

The primary documentation for RBS will be this wiki. Please share your ideas on thingiverse, google sketchup, and so on, but please first upload and share on this wiki. Thank you.

License

GPL.

Innovation - Why is this new?

Erector-set-like technology is old. But making 2' by 4' CNC routers from it, and making gears with it is new.

Also, this system will be cross compatible with old systems like erector-set,meccano, and the other European systems ??? and will be compatible with anything with the right hole spacing Vex, etc.

We could emulate Lego if we wanted, but Lego is not compatible with building systems like 10 foot long, 2 inch wide square steel tubing. And we need tubing like that to make our CNC routers.

Inventors

Gridbeam - ? Modular Building Systems - Eiffel. RepRap - Dr. Adrian Bowyer Erector Set - ?