Quad

Please do not add to this page. (It is slightly overcrowded as it is.)

This Page Contains multiple RepRap development projects and should be split up. Each individual project/design/improvement should have its own development page within an encompassing category.

//identifies pages under construction.

This page is a development stub.

Release status: Concept

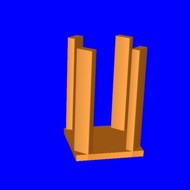

The Quad design intends to address three areas of concern. Instead of three columns, Quad uses four columns allowing effector tilting, which one day might be useful for milling but should certainly address the problem of hotend tip alignment and dragging that is worse when, say *four* hotends are in one effector; allowing a square, not round hotbed, which admits of laminated Peltier chip design, consequently if a range which is cold enough obtains, through differential thermal expansion, allowing part auto release without scraping. Part auto release could allow machine self replication = Quad also incorporates a new spider rod joint design also intended to have no backlash and it may be possible through some optimization of dimensioning and clearances to allowing milling such as of the hot cold bed cold side air channels.

Quad will probably have dual drives for each filament because some of the flexible filament for shoes and conductive work are quite unmanageable-they would be synchronized 2, 3, or even more points of engagement--and would have four hotends standard because of the effector tilt feature.

Drop shutters between a plate hanging from the spider arm drive blocks would contain the air near the hotbed and a fan above the base would allow flow or cooling to be gated between them, fighting the tendency of just cast material and aggregate cast material to cool and warp, forming a partial enclosure. Tensile members threaded with a bicycle spoke threader would stiffen the frame.

So the design is a testbed for more then one idea and you are free to adapt or run with any of them.

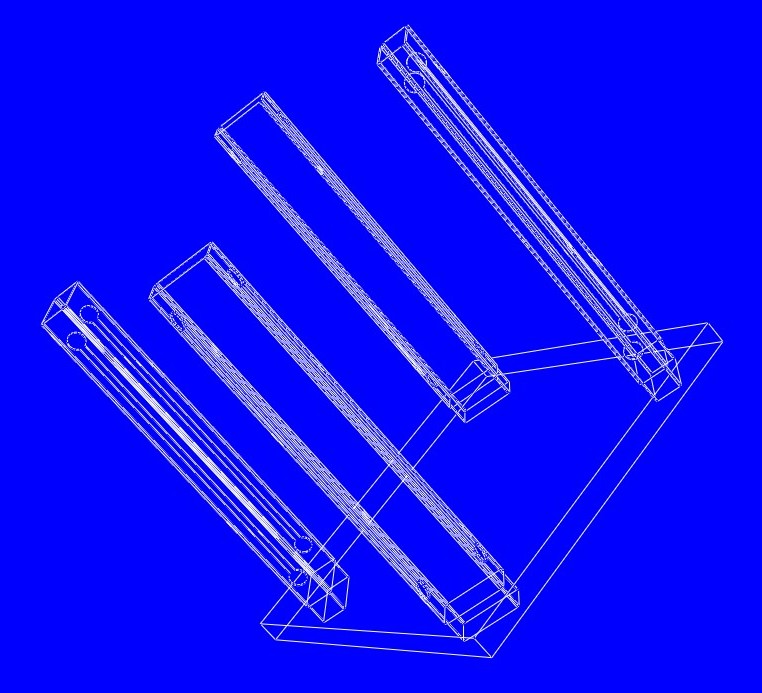

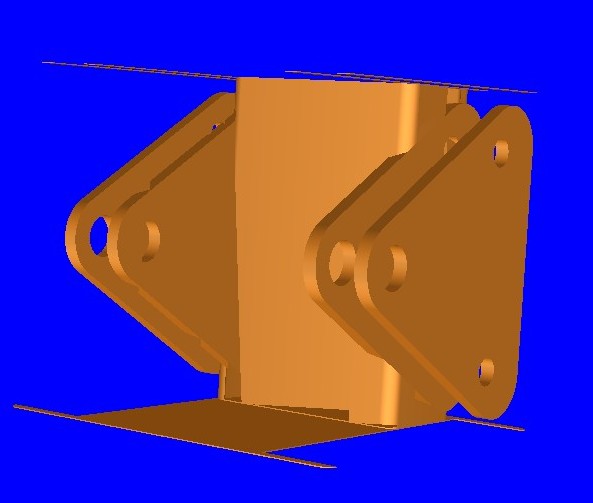

The way I'd build it would be hollow rectangular tubing with sliding blocks inside on leadscrews:

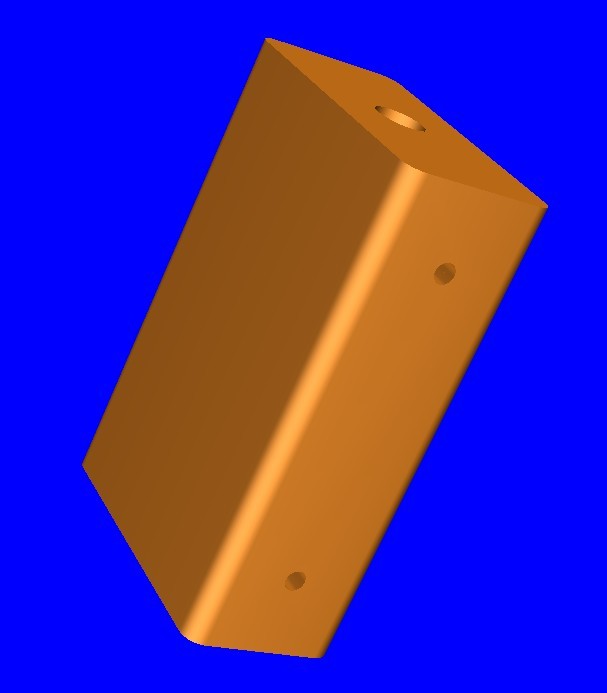

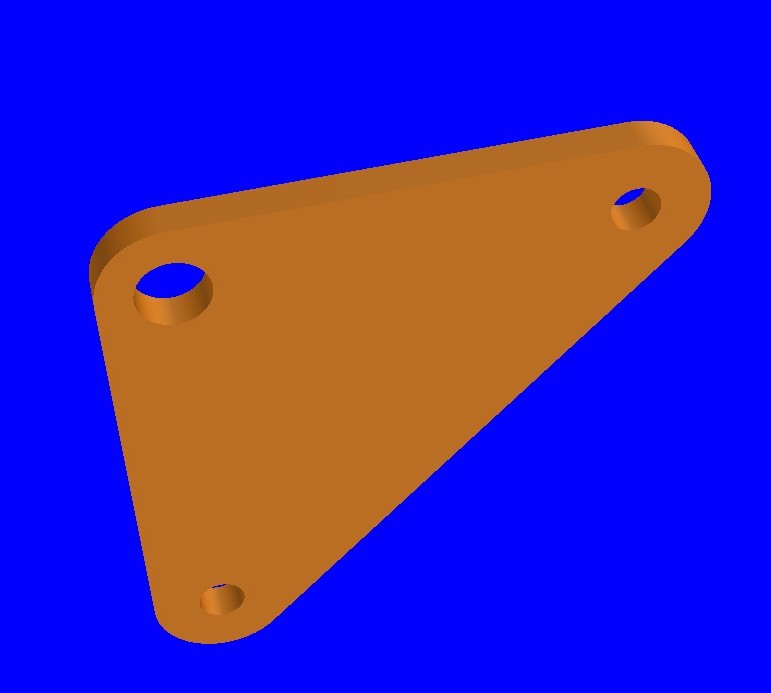

Each block would capture two plates on opposite sides spaced rightly.

Each pair of plates would capture one ball strut end.

The effector would likewise capture ball strut ends. Sophisticated sockets wouldn't be needed.

A wireframe base detail shows the slots.