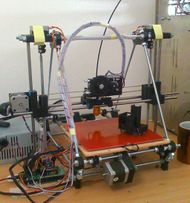

Prusa Mendel/es

Traducciones de esta página

Alemán: Prusa Mendel in het Nederlands

Release status: Funcionando

| Description | Prusa Mendel es una versión simplificada de una Mendel.

|

| License | |

| Author | |

| Contributors | |

| Based-on | |

| Categories | |

| CAD Models | |

| External Link |

- Si está construyendo esta máquita usando el sistema métrico inglés / Americano (o SAE imperial), véase también SAE Prusa Mendel.

Prusa Mendel es el Fort T de las impresoras 3D.

Al igual que el Modelo T, la Mendel Prusa mejora el diseño anterior al ser más ágil para la fabricación. La Mendel Prusa es un remix simplificado del original Mendel. Por defecto, se utilizan casquillos impresos en lugar de rodamientos normales, aunque las opciones para sustituirlos por cojinetes baratos lm8uu o de otro tipos de cojinetes o bujes están disponibles. La versión actual utiliza en total tres cojinetes de 608, uno para el eje X y dos para el eje Y. Los rodamientos de 624 ya no son utilizados.

El objetivo principal de Prusa es ser la impresora 3D más sencilla que usted pueda construir.

- Es mucho más simple de construir.

- Es mucho más simple de modificar.

- Es mucho más simple de utilizar.

- Es mucho más simple de reparar.

Debido a su complejidad, Prusa Mendel es un proyecto vivo en continua actualización. Esto, que es una característica única, debería ser la norma.

Contents

<videoflash>tyVM3-v84I0</videoflash>

Desarrollo

El desarrollo de Prusa Mendel está alojado en github: http://github.com/prusajr/PrusaMendel.

Puede seguir los cambios en Changelog.

También puede darse de alta gratuitamente en github y participar en el proyecto.

Historia

Lista de Materiales

Partes Imprimibles

Partes No Imprimibles("vitaminas")

Tenga en cuenta que las partes adicionales son necesarias para la extrusora, aunque algunas partes extrusora se incluyen en la tabla de abajo.

| Cantidad | Descripción | Tipo | Commentarios |

|---|---|---|---|

| 83 | M8 nut | Fastener | Buy a 100-pack to be on the safe side. |

| 93 | M8 washer | Fastener | Buy a 100-pack to be on the safe side. |

| 6 | M8×30 mudguard / fender washer | Fastener | |

| 2 | M4×20 bolt | Fastener | To mount the extruder |

| 2 | M4 nut | Fastener | To mount the extruder |

| 2 | M4 washer | Fastener | To mount the extruder |

| 22 | M3×10 bolt | Fastener | |

| 16 | M3×25 bolt | Fastener | Or eight M3×25 bolt plus eight M3x20 bolts. The M3x25 bolts are too long for the recent Prusa z-motor-holder and rod-clamp, and also for the Z motor couplings. See Section 8, steps 4 and 13 for details. |

| 4 | M3×40 bolt | Fastener | |

| 70 | M3 washer | Fastener | |

| 40 | M3 nut | Fastener | 8 optionally locknut / stop nut / nyloc |

| 2 | M3 grub screw / set screw | Fastener | M3x8 seems about ideal but anything 6mm or longer should do. If these are hard to get, additional M3×10 bolts will do the job instead. |

| 3 | 608 roller skate / inline skate / skateboard bearing | Bearings | |

| 4 | ballpoint pen springs | Spring | To fit over M3 bolts. Ballpoint pens are a common, cheap source of suitable springs. They are about 25mm long and compress to about 10mm. |

| 6 | M8×370mm | Threaded rod | 3 per side Note: The threaded rods can be cut from larger 6x1m pieces (see Threaded Rod Cut Order below). |

| 4 | M8×294mm | Threaded rod | front / rear |

| 3 | M8×440mm | Threaded rod | top / bottom |

| 2 | M8×210mm | Threaded rod | Z-leadscrew |

| 1 | M8×50mm | Threaded rod | or M8x30 or longer bolt for X idler. Take care: if the bolt is too long, it may not be threaded along a sufficient length |

| 2 | 8mm×420mm | Smooth rod | X-bar Note: 304 Stainless Steel or A2 Tool Steel are recommended for smooth rods as it can help to prevent friction from rust and manufacturing (straightness) standards are higher. Rust issues can be prevented on the normal steel rods by maintaining a coat of oil. The smooth rods can also be cut from larger 3x1m pieces (see Smooth Rod Cut Order below). |

| 2 | 8mm×406mm | Smooth rod | Y-bar |

| 2 | 8mm×350mm | Smooth rod | Z-bar |

| 1 | 225mm×225mm print top plate | Thick Sheet | |

| 1 | 140mm×225mm print bottom plate | Thick Sheet | |

| 1 | 840mm×5mm T5 pitch timing belt | Belt | Y axis |

| 1 | 900mm×5mm T5 pitch timing belt | Belt | X axis |

| 5 | NEMA 17 bipolar stepper motor | Stepper | Be sure to get ones with at least 20mm of shaft length. Shorter shafts require modifications to the X pulley assembly and Z motor couplers. One of the five motors, for use with the extruder, should be capable of creating a holding torque of at least 40Ncm, at the very least. |

| 50 | small cable binder / ziptie | Misc | |

| 1 | Wade's Geared Extruder | for 1.75mm filament RepRap Universal Mini Extruder; or any other compatible extruder for either | |

| 1 | Electronics + endstops | This can be RAMPS, Sanguinololu, Gen6, Gen7, Gen3, or any other Mendel compatible electronics. Endstops are either optical switches or microswitches (Recommended), and you need three, one for each of the X, Y, Z axes. |

| Quantity | Description | Type | Comments |

|---|---|---|---|

| 3 | 30mm×10mm Optoflags | Thin Sheet | if using opto endstops |

| 2 | 8mm ID spring | Spring | to eliminate backlash in the z axis |

| 1 | object with precisely 290mm length | for frame alignment | |

| 1 | object with precisely 234mm length | for frame alignment |

Note: You can combine the latter two by having a piece of thick sheet with dimensions 290mm×234mm. Make sure to mark which side is which.

Threaded Rod Cut Order (when cutting from 1m lengths):

Required: 6x1m Long 8mm Threaded Rods (or 5x1m pieces + 1x50cm piece) Rod 1: 370mm, 370mm, 210mm, ~50mm (The last piece will end up somewhat shorter than 50mm. ) Rod 2: 370mm, 370mm, 210mm, ~50mm ( Use it for your idler. Alternatively, an M8x30 or ) Rod 3: 370mm, 294mm, 294mm, ~42mm ( longer bolt can be used. ) Rod 4: 370mm, 294mm, 294mm, ~42mm Rod 5: 440mm, 440mm, ~120mm Rod 6: 440mm

Smooth Rod Cut Order (when cutting from 1m lengths):

Required: 3x1m Long 8mm Smooth Stainless Steel Rod Rod 1: 420mm, 420mm Rod 2: 406mm, 406mm Rod 3: 350mm, 350mm

The Prusa Mendel uses the 4 drivers in the standard Mendel electronics package to drive 5 motors by using two steppers wired in parallel to one driver [1].

Where To Purchase

See the Mendel Buyers Guide for information on where to purchase all of the parts needed.

Printing the Parts

Printing a Prusa on a Mendel

The pre-assembled build file is an easier option for printing Prusa parts from a RepRap Mendel. With this option you only need to print mendelplate.stl and pla-bushing.stl to get a complete set of printed parts for the Prusa Mendel:

- Mendel Plate (contains all printed parts except the PLA Bushings)

- PLA Bushing

Printing a Prusa on a CupCake CNC

There are also pre-assembled build files available to fit your CupCake CNC's build area (download using right click => save as)

Note:

- These plates are 85x95mm in size.

Plates for the MakerBot (the plates have changed, these print times are no longer accurate):

- Makerbot Plate 1=> 6 hrs 30 min

- Makerbot Plate 2=> ~2 hrs 30 min (needs retesting)

- Makerbot Plate 3=> 5 hrs 40 min

- Makerbot Plate 4=> 2 hrs 30 min

- Makerbot Plate 5 => 1 hr 50 min

Printing a Prusa on anything else

Last but not least, if you have a machine that doesn't fit into any of the previous options all the .stl files necessary to print a Prusa Mendel are available on the PrusaMendel Github where you can download them and print them individually.

Buy the printed parts

Mendel_Buyers_Guide#RepRapped_Parts_Kits

Assembly

- Assembly instructions >> Prusa Mendel Assembly.

- Required Tools

Media

- Two printers simultaneously - Prusa and shaper cube working side by side.

- Prusa homing using endstops

- Prusa development overview

- Prusa Y axis stress test

- Prusa Z axis stress test

- Early preview of the Prusa Mendel redesign

- Fumon's Prusa build session 1 - D1plo1d building Fumon's Prusa Mendel at Hacklab.to. Should give a hint as to how the Prusa Mendel parts go together.

Prusa Improvements/Hacks

- Rob's Auto-centering shaft coupler - designed to reduce shaft/motor vibrations (print 2/replaces 2x coupler). May require widening the openings on the z motor mounts to allow the rotation of the zip tie. Use a zip tie gun to get maximum compression on the coupling.

See Also

External Links

- Prusa's Blog

- Prusa Builder Blog Feed

- Assembly photo gallery

- Prusa Mendel Visual Instructions - A nicely formatted version of the assembly process in PDF.

- Paperback version the Prusa Mendel Visual Instructions, also available in color.

- Prusa Mendel Assembly Video Tutorial This video, the first of a series, provides an overview.