PonokoRepRapXMotorAssembly

Ponoko RepRap X Motor Assembly

| [PonokoRepRap Main Ponoko Page] | ||

| Prev Step | Next Step | |

| BOM for this page |

The X Motor assembly can be fitted with either a NEMA17 or NEMA23 stepper motor. With the larger NEMA23 design, the motor body itself is used to trap the X Carriage guide rails to the X Motor Bracket. With the NEMA17, the motor is screwed directly to its bracket and acrylic clamps are used to hold the guide rails in place.

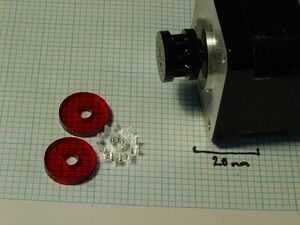

First, locate the size of rims and gear that (a) fits the shaft on your stepper motor, and (b) fits the type of ball chain that you have purchased. The rims and gear are cut for a 4mm and 6mm shaft. If you have a 5mm shaft, look for the larger ball chain gear. In its hole you will find a 5mm collet. Carefully separate the collet from the gear and use it to adapt your 5mm shaft into a 6mm shaft. If the gear or rim does not quite fit the spindle of the motor, file away on the interior flat surface of the gear or rim with a small flat file until it just fits. If you have no flat on your stepper motor, clamp it in the jaws of a vice and put one there with a 2nd cut file.

Once you have something that fits on, scrape the motor shaft with the file a bit to give it some edges to catch the epoxy, and epoxy the rim/gear/rim sandwich into place right at the end of the shaft. Make sure all is square before the epoxy sets.

Try not to fill the teeth of the gear with epoxy. If you do, try not to wipe it out with a solvent-soaked rag that dissolves the acrylic...

Some form of test on some scrap is in order.

Here is a complete set of parts for the X Motor Assembly, using a NEMA 17 stepper motor. For a NEMA 23 motor, two of the Rail Clamps and their fastenings will not be needed, but <part a="ifNEMA23">4 M5 25mm screw</part>s with <part a="ifNEMA23">8 M5 washer</part>s and <part a="ifNEMA23">4 M5 nut</part>s not shown here will be:

Put <part p="4 M3">washer</part>s on <part>four M3 16mm screw</part>s, and insert them into the X End Spacer as shown. Only use <part p="4 M3">nut</part>s, not washers on the other side as these nuts will become captive later.

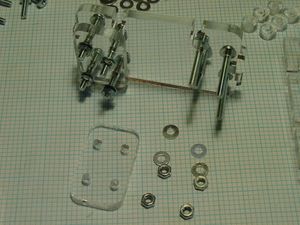

Locate these parts for assembling the X Motor Bracket from the 5mm acrylic sheet:

<repeat count="2"> (NEMA17 Only) Put <part p="4 M3" a="ifNEMA17">washer</part>s on <part a="ifNEMA17">four M3 25mm screw</part>s and put them through a rectangular Rail Clamp. Insert this into the matching four holes in the large X Motor Bracket and secure with <part p="4 M3" a="ifNEMA17">washer</part>s and <part p="4 M3" a="ifNEMA17">nut</part>s. Repeat for the matching Rail Clamp on the X Motor Bracket. </repeat>

Locate the parts for the X Motor Lower Bracket as shown here:

Take the X Motor Lower Bracket and attach the two Rail Clamps as per the X Motor Bracket, but insert the four M3 25mm screws into the Bracket first, not the Clamp. <repeat count="2"> Put <part p="4 M3" a="ifNEMA17">washer</part>s on <part a="ifNEMA17">four M3 25mm screw</part>s and put them through the Bracket first (not the Rail Clamp as you might have done for the X Motor Bracket). Insert this into the matching four holes in the Rail Clamp and secure with <part p="4 M3" a="ifNEMA17">washer</part>s and <part p="4 M3" a="ifNEMA17">nut</part>s. Repeat for the matching Rail Clamp on the other end of the X Motor Lower Bracket. </repeat>

The completed X Motor Lower Bracket Assembly.

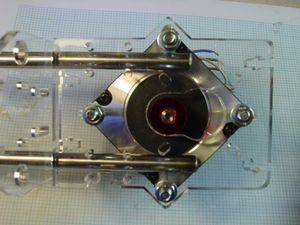

Assembling the Y Saddles is exactly the same as building the ones for the X Idler Assembly. Recapping: Assemble one Y Saddle with the 5mm chain clamp against one side, and a second with it on the other. The two clamps should be mirror images of each other. Use <part>4 M3 20mm screw</part>s, a pair of <part p="8 M3">washer</part>s each, and <part p="4 M3">nut</part>s.

Just to remind you, this is the order in which the Y Saddles are braced together. Put <part p="2 M3">washer</part>s on <part>two M3 40mm screw</part>s and slide them into the clamp side of one of the Y saddles. Slide on one or two <part p="4 M3">washer</part>s - the exact number depends on the thickness of your "8mm" and "5mm" acrylic. You might not need any.

Attach the Y Saddle Assembly to the End Spacer using <part>four M3 12mm screw</part>s with <part p="four M3">washer</part>s, and captive <part p="four M3">nut</part>s as with the X Idler Assembly. Do not tighten fully. Wait until the X Axis Assembly is mated with the Y Axis for that.

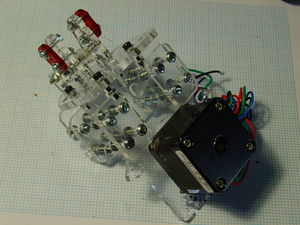

If you're using a NEMA 17 motor, fit it now. Don't know what kind you're using? NEMA 17 only fits the small set of 4 slotted holes, NEMA 23 only fits the larger set that extend into the little triangular "wings" on the X Motor Bracket.

(NEMA23 Only)If you're using a NEMA 23 motor, you will fit it later, using it to trap the Guide Rails against the X Motor Bracket as shown here:

If the NEMA23 motor appears unstable due to short rails or a strangely-shaped front on the motor, chock up the far corner with a piece of scrap 8mm acrylic.

When it's all put together properly, the X Motor Assembly (this one fitted with a NEMA 17 motor) looks like this:

Now put all the X Axis parts away safely and we'll move on to the [[[PonokoCornerAssembly|Corner Assemblies]].

| [PonokoRepRap Main Ponoko Page] | ||

| Prev Step | Next Step |

-- Main.VikOlliver - 07 Nov 2008