Paul Bunyan

|

English • العربية • български • català • čeština • Deutsch • Ελληνικά • español • فارسی • français • hrvatski • magyar • italiano • română • 日本語 • 한국어 • lietuvių • Nederlands • norsk • polski • português • русский • Türkçe • українська • 中文(中国大陆) • 中文(台灣) • עברית • azərbaycanca • |

Release status: unknown

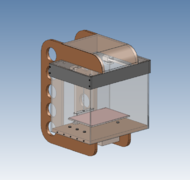

| Description | Large sturdy printer made from North American hardwood plywood

|

| License | |

| Author | |

| Contributors | |

| Based-on | |

| Categories | |

| CAD Models | |

| External Link |

This page represents an example development page and showcases many features that can be used in creating new development pages.

| |

This page is currently under development. Stop back when it's completed to read more about the printer. |

Contents

Design Goals

Most RepRaps are designed with many constraints, and the purpose of this RepRap is to fill a niche by maximizing certain features while completely ignoring some other constraints that I don't find are too important. If you are concerned with the constraints listed in the first category below, this RepRap is not for you. I'm going to discuss the following section informally as to show the reader the thought process behind the design.

Features I don't care about

Here are some design constraints that were largely ignored in favor of some more important features:

- Weight: I do not care about portability as the printer will very rarely move. As long as it isn't made out of concrete the weight won't be a factor.

- Size: Apart from those who live in a very small apartment, I don't see size being important. I'll obvious try to minimize materials used, but it is cost effective in this case to make a larger wood frame as opposed to a smaller aluminum one.

- Cost: I actually do care about keeping this printer fairly cheap, but I'm not going to cut corners and shave every single dollar off of the price tag at risk of compromising one of the aspects below. The idea is that this printer is for people who want an upgrade from a "lighter" RepRap and are willing to spend a little but more.

Key Aspects of Design

Here are the things I do care about and have tried to maximize in the design of the printer:

- Using local resources: This is the true inspiration for the project. From my time spent on longboard building forums I have learned that here in the Midwest we have better and cheaper access to good plywood than almost anyone in the world. Most RepRaps have been designed in the UK and Europe where these raw materials aren't as abundant. The goal of this design is to fully utilize that advantage. This is also where the name comes from: if you're not from Minnesota or haven't heard of him, read up on the legend of [Paul Bunyan](https://en.wikipedia.org/wiki/Paul_Bunyan).

- Integrity: The thick wood frame may be overkill, especially with the small metal frame holding the axis in place, but the next two features are very contingent on a sturdy frame.

- Speed: I want this printer to print fast. This means a robust frame, ultra-light carriage, CoreXY axis, and plenty of cooling at the hotend. The projected load on the axis motors is already under a tenth of that in the Prusa models.

- Precision: Both temperature and positional. The temperature control will be the most crucial aspect of the design- a thermocouple and heater in the enclosed chamber will keep the interior at an optimal printing temperature for the duration of the print. The axis will be framed in MIC 6 or a similar cast aluminum that is very very stable. Though plywood is also very stable it is in fact only wood, but the auto bed-leveling will take care of that.

Features I shouldn't care about but do

I realize that it looks a bit ridiculous, but aesthetics and novelty were core parts of the inspiration for the printer. Simply put, I tried to maximizes form without sacrificing any function.

Features

- Print Size: 8"x11" (200mmx280mm)

- Print Height: 10" (250mm)

- Resolution: 25 microns

- Auto bed Leveling

- Full enclosure temperature control

- AC powered heatbed Less than 90 seconds to 100C

- CoreXY axis setup

- Max. Print Speed: 200mm/s (estimated)

Pictures

Coming Soon.