Parallel extruder

This page is a development stub. Please enhance this page by adding information, cad files, nice big images, and well structured data!

very, very basic ideas so far here. Many people are talking of tool switching, which if i understand correctly would be removing an extruder (gears and all) from the machine and placing a new one, or at least rotating out the tools. Therefore i doubt that i understand it because that would be horrendously wasteful.

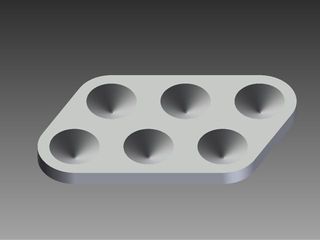

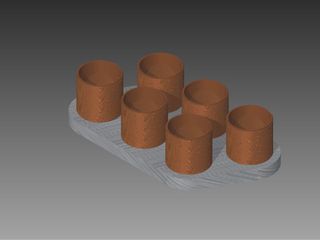

the distance between the actual nozzles on the aforementioned piece should be equal to one step (IE, one bead of melted plastic) so that if you DON'T need multiple materials, you can run say ABS through all 6, and print with 6x speed, since your moving 3 steps then dropping 6 beads, rather than move one drop one move one drop one.

Now the rest i haven't even sketched in Inventor yet, but basically place the extruder parallelogram next to the gear, with the stepper motor on the opposite side, then have each nozzle function as a bowden extruder.

excuse me for being incoherent,i've put off assembling my reprap until christmas break so it doesn't cut into schoolwork, so i have an academic understanding of all this, not a functional one.